Installation Waukesha Cherry-Burrell

®

Brand C-Series Pump

Page 14 95-03008-IEC 01/2019

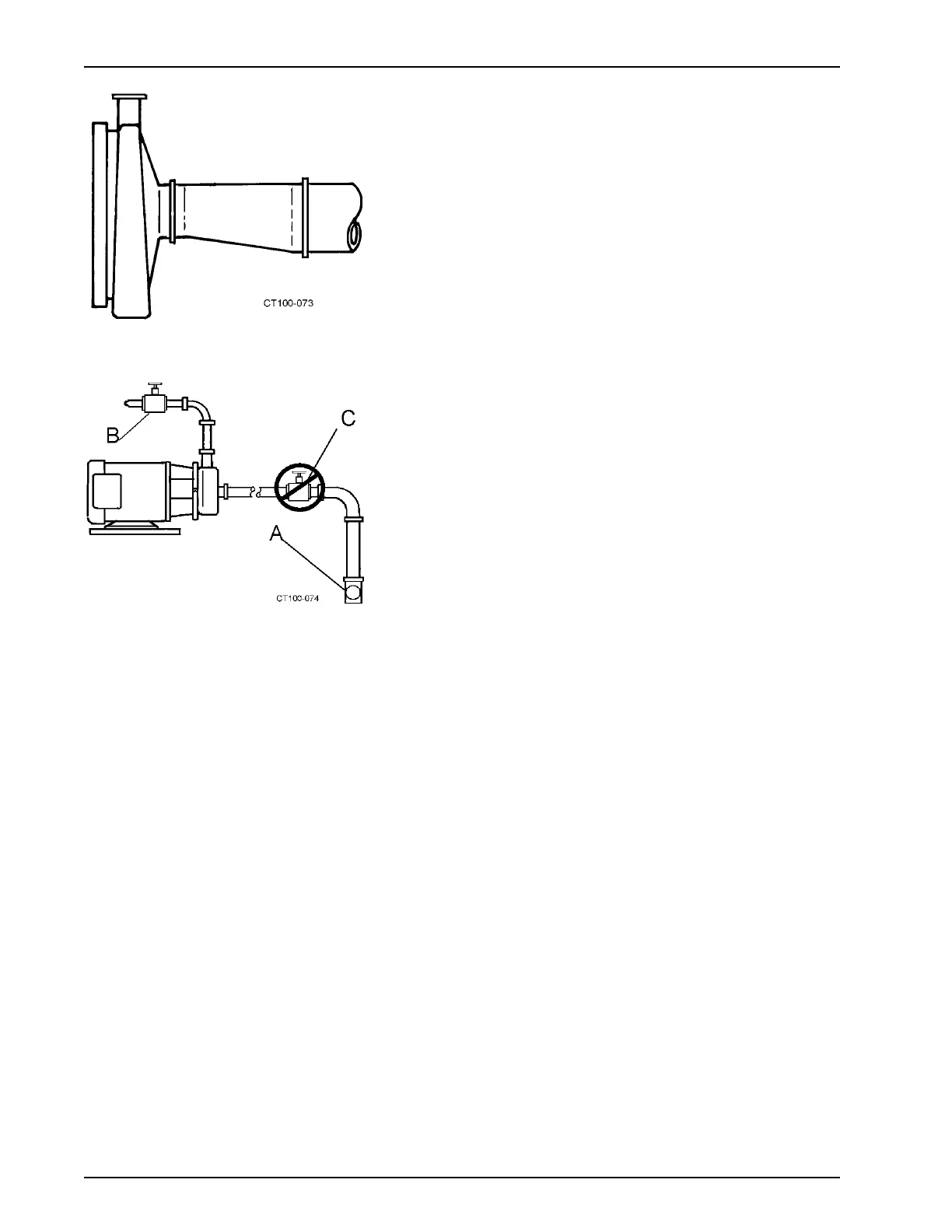

• If a reducer is connected to the inlet, use an eccentric type to

prevent problems due to trapped air. See Figure 6.

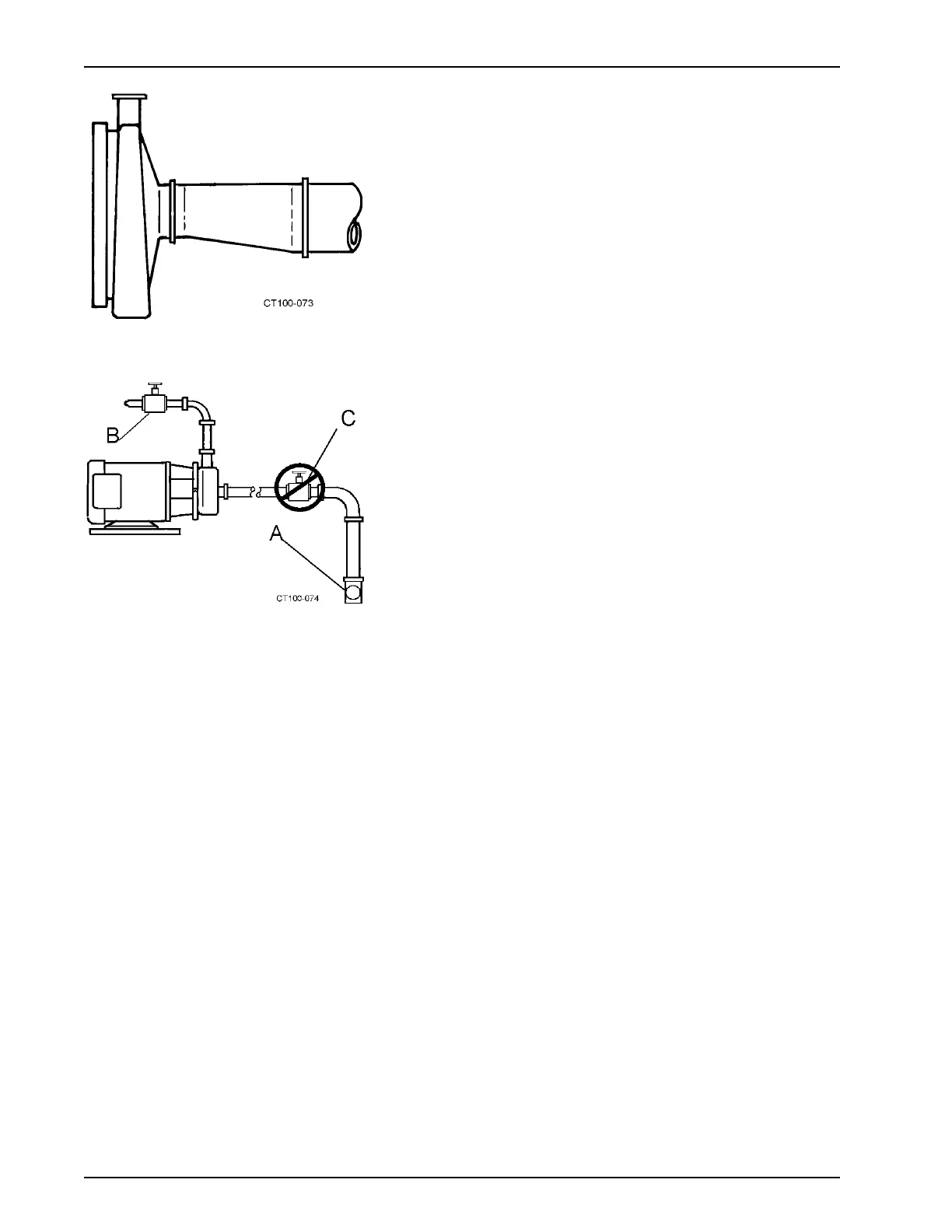

• This pump is not self-priming. If the pump is installed above

the supply liquid level, install a foot valve or other system

check valve (Figure 7, item A) to keep the system flooded for

priming.

• A throttling valve may be required to control the pump flow

ra

te to prevent motor overload. Always install a throttling

valve (Figure 7, item B) in the discharge piping and at least

10 diameters from the pump outlet. NEVER install a throttling

valve in the supply piping (Figure 7, item C).

Installations that may

cause operation problems

• Any system throttling valves or similar devices to control flow

rate must be installed in the discharge line. DO NOT install

any system throttling valves or similar devices to control the

flow rate in the supply line. (See Figure 7.) Restriction in the

supply line may cause cavitation a

nd pump damage.

• “Water hammer” in the system

can damage the pump and

other system components. Water hammer often occurs when

valves in the system are suddenly closed, causing lines to

move violently with a loud noise. One way to eliminate water

hammer is to slow down the actuation speed of the valve.

• Do not expose the pump to freezing

temperatures with liquid

in the casing. Frozen liquid in the casing will damage pump.

Drain the casing before exposing it to freezing temperatures.

Figure 6 - Correct Eccentric Installation

Figure 7 - Valve Piping Installation

Loading...

Loading...