9

TECHNICAL DATA

Manufactured Smokeless Fuel :

Max:

Nominal:

Room Water Total

5.5 kW 14 kW 19.5

5.0kW 10.6kW 15.6

Typical refuelling intervals to obtain nominal outputs: MSF 4 hours

Flue Gas Mass Flow: MSF 9.8 g/s

Flue Gas Mass at nominal output: 357

o

C

Gross Weight: 239 kgs

Flue Outlet: 150mm

Flue Draught: 12 Pa

Boiler Tappings: 1” BSP

Max Water Pressure: 2 Bar

Efficiency (obtained at nominal heat output) 76.1 %

WARNING: DO NOT OBSTRUCT PRIMARY AIR SUPPLY TO THE AIR DUCT AT THE RIGHT HAND

SIDE OF THE STOVE

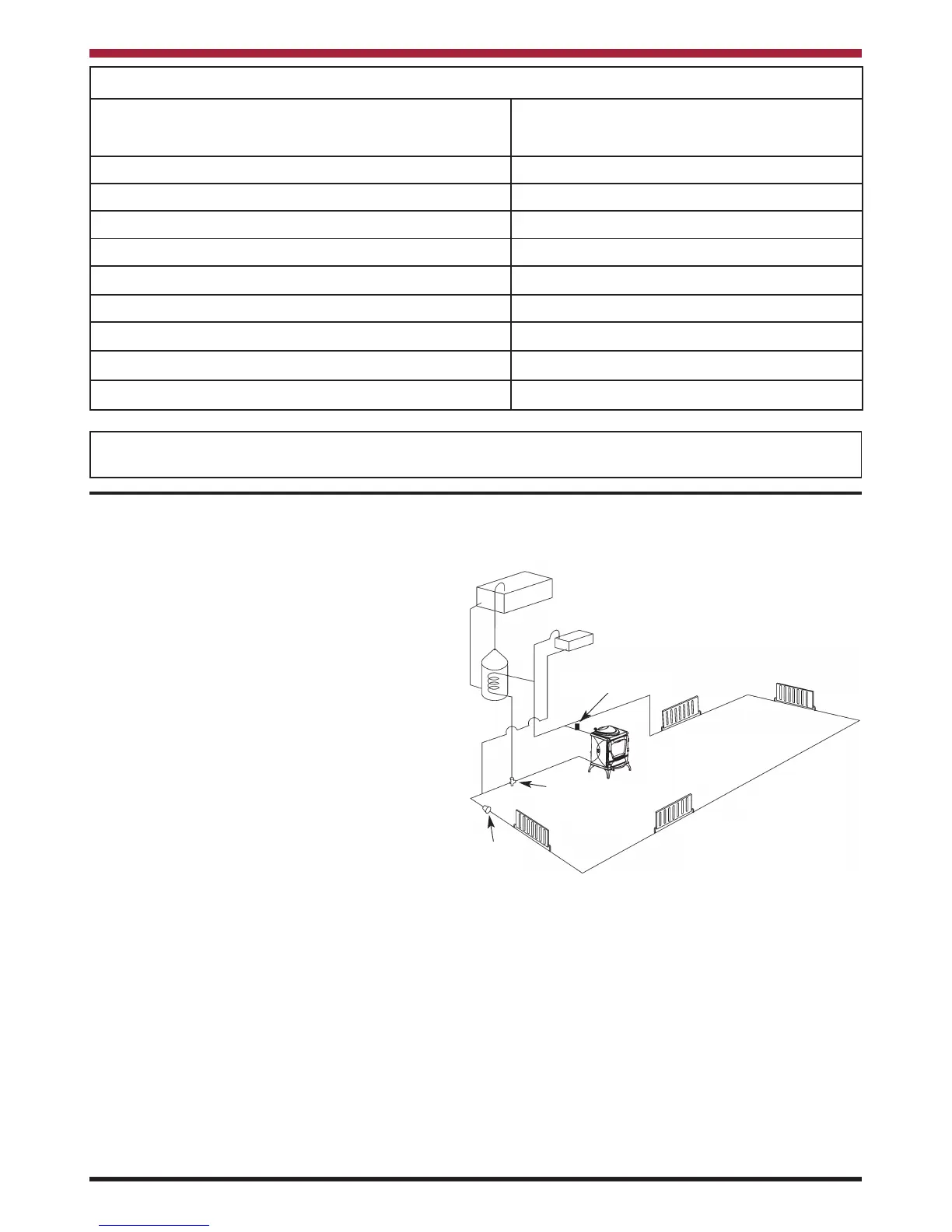

PLUMBING

REGULATIONS

The plumbing must be in accordance with all

relevant regulations and practices. It must include a

gravity circuit with expansion pipe, open to the

atmosphere. The central heating will normally be

pump-driven as with other types of boilers.

GRAVITY CIRCUIT

The gravity circuit consists of the domestic hot water

tank of 135 litres indirect cylinder, fixed in an upright

position, recommended for hot water storage and it

should be connected to the boiler by 28mm diame-

ter flow and return piping. The pipes should not

exceed 7.8 meters (25ft) in length and cylinder and

pipework should be fully lagged. The shorter the run

of pipe work the more effective the water heating.

There must be no gate valves on this circuit and it

must have an expansion pipe exhausting to

atmosphere. Cylinder and pipe work should be

lagged to minimise heat loss.

This diagram illustrates the basic principal of water

heating systems and must not be regarded as a

working drawing.

Fig.9

Pipe Thermostat

Injector Tee

Pump

INJECTOR TEE

Where the gravity and central heating circuits join

together to return to the stove we recommend the

use of an injector tee connection, situated as close

to the unit as possible. This type of tee encourages

a stable flow of hot water through both circuits and

helps to prevent priority being given to the stronger

flow, which is most commonly the pumped central

heating circuit. This way, there will be no shortage

of hot water to the taps when the heating is on.

Loading...

Loading...