32

13406 SE 32nd St, BELLEVUE WA, 98005 WWW.CONSUMER.STEPPIR.COM TEL: (425)-453-1910

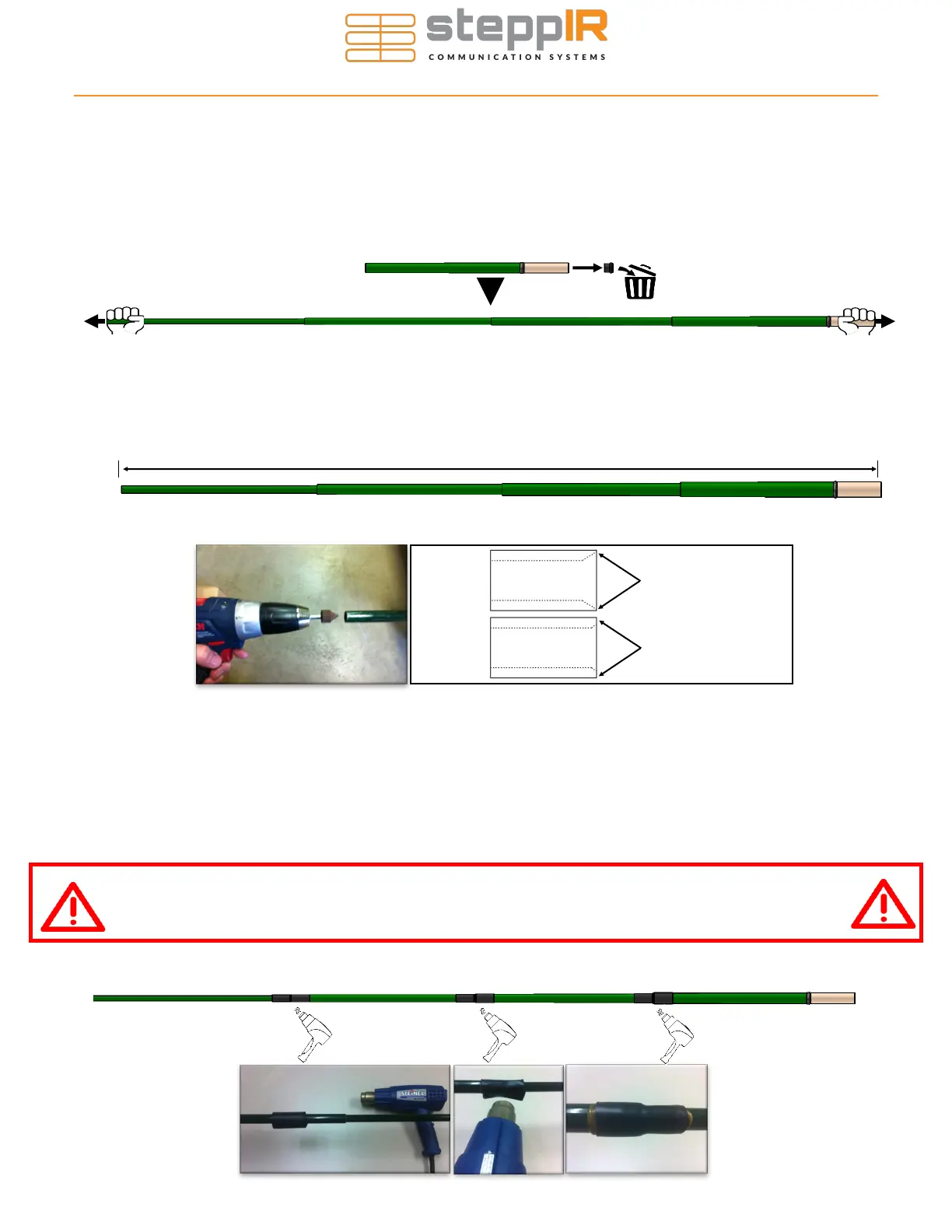

PREPARING THE TELESCOPING POLE

1. Extend the telescoping poles (PN 10-1013-02) to full length by firmly locking each section of the pole in place. A good

methodology is to position each half of the joint so that they are several inches apart (while still within each other), and

then pull quickly and firmly as shown in Figure 6.11. Do this for each pole. There are rubber plugs inside the base sec-

tion of each telescoping pole. These make it easier for handling, but they MUST BE REMOVED BEFORE ASSEMBLY.

VERIFY THE FOAM INSERT IN THE PLUG HAS NOT MADE ITS WAY DOWN THE POLE AND THAT THERE IS NO

OTHER FOREIGN DEBRIS INSIDE THE POLE.

2. With the poles fully extended, trim the end of the tip element of each pole so that the pole is 212.75” from the tip of the

pole to the butt end, as shown in Figure 6.12. ONLY trim the poles used for the 40/30 loops—if your antenna has 20m-

6m straight elements, those should not be trimmed (must have a length of at least 213.1”). Use a hack saw, pipe cutter,

or similar cutting blade that is suitable for fiberglass. Be sure that you cut the pole perpendicular to the length of the pole

so that it is as “square” as possible.

3. Using the conical drill bit, chamfer the tips of the 40/30 poles as shown below. The image Figure 6.13 below shows

the proper angle to chamfer to. Clean out the interior of the fiberglass poles after chamfering it.

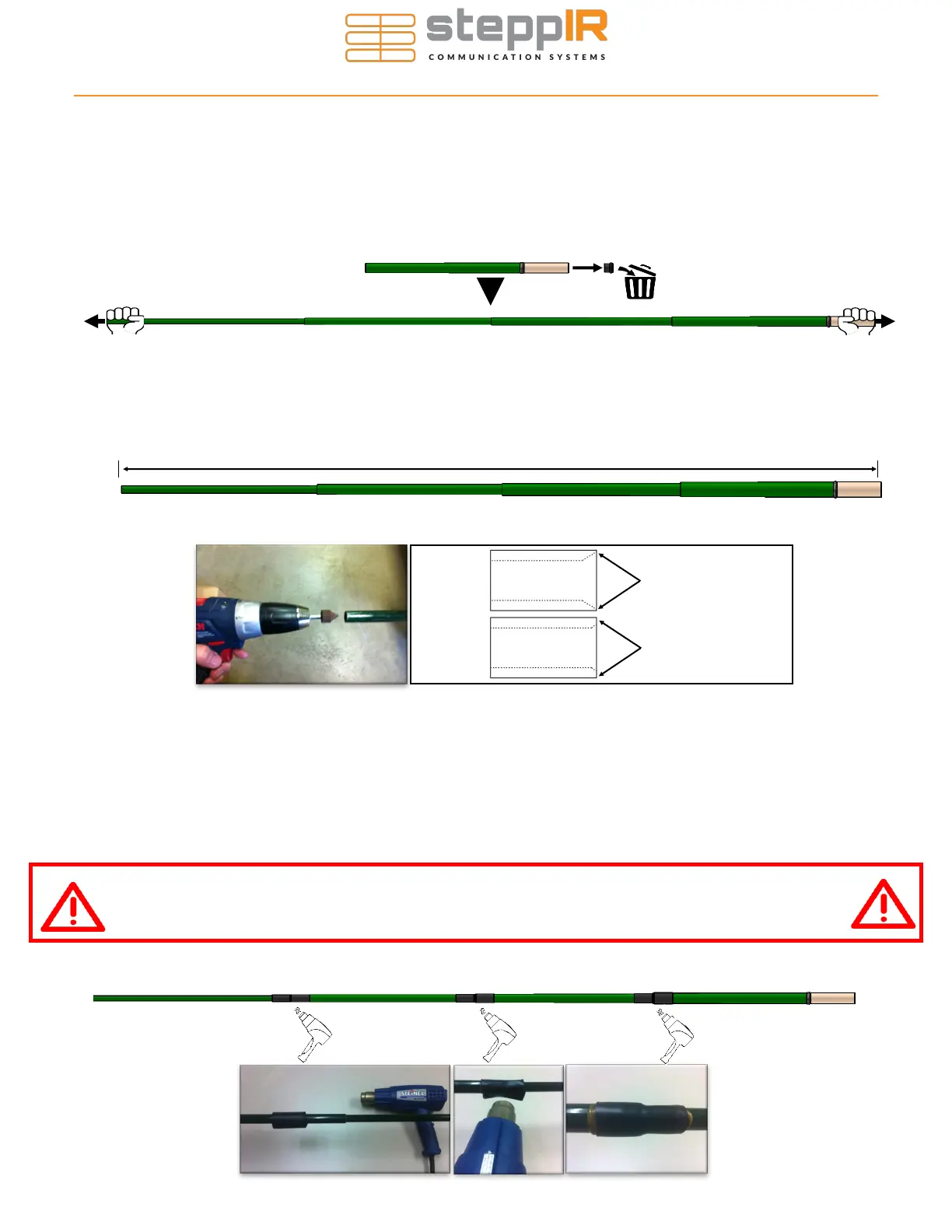

4. Each telescoping pole uses 3 polyolefin heat shrink pieces, one covering each joint after it has been pulled tight. Once

finished, the seal is secure and waterproof. This product requires a heat gun for activation of the adhesive.

5. When positioning the heat shrink, place it so that the joint of the telescoping pole is centered in the middle of the heat

shrink.

6. Using a heat gun as shown in Figure 6.14 (hair dryers will NOT work), apply heat evenly around the entire area of

heat shrink. Note: there are 4 blue colored lines imprinted on the tubing. The joint is considered done being heated and

waterproof when the lines change color to a yellowish green. Each line needs to change color to ensure even adhesion

temperatures.

7. The heat shrink will want to slide as it is heated so wear gloves and reposition the heat shrink to keep it centered on

the joint as needed. Caution: The heat shrink will be HOT, wear insulated gloves!

212.75”

Section 6.1: Preparing the fiberglass pole

LOOK INSIDE OF THE TELESCOPING POLE TO VERIFY NOTHING IS BLOCKING IT. YOU

SHOULD BE ABLE TO SEE LIGHT AT THE OTHER END IF THE POLE IS KEPT STRAIGHT. DEBRIS

INSIDE THE TELESCOPING POLES CAN LEAD TO FAILURE OF THE EHU.

Figure 6.11

Figure 6.12

Figure 6.13

Chamfered end meets

edge of pole OD

Correct

Incorrect

Chamfered end does

not meet edge of pole

OD

1.1” x 6”

(PN 10-1059-21)

Figure 6.14

1.5” x 6”

(PN 10-1059-01)

1.5” x 6”

(PN 10-1059-01)

Loading...

Loading...