8.3.3 Checking the flow rate (during heat pump commissioning)

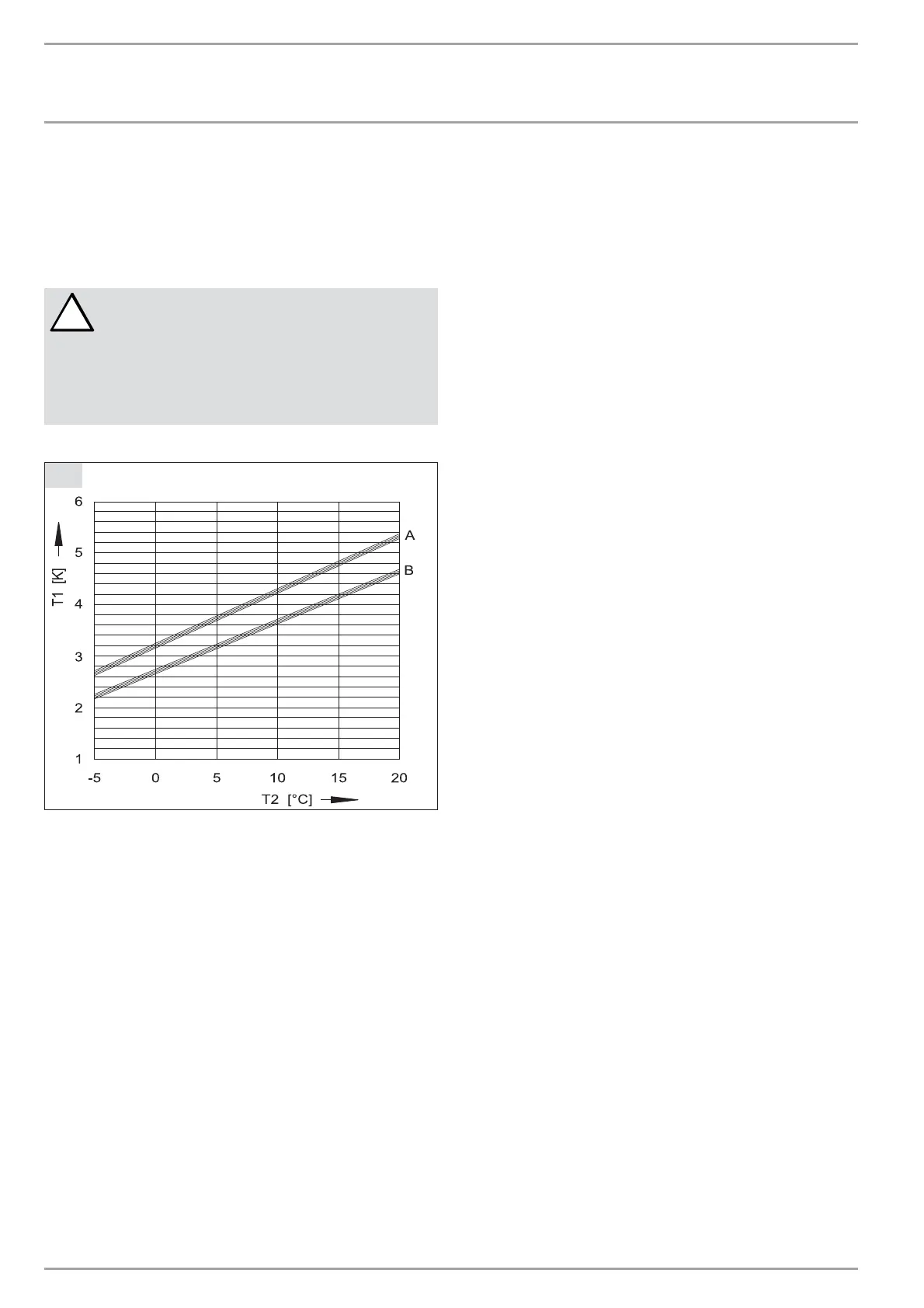

Check the flow and return temperatures of the heat source. For

this, determine the temperature differential by measuring the

temperature under the thermal insulation on both flow and

return pipes of the heat pump. The diagram (Fig. G) shows the

temperature spread at the nominal flow rate.

!

Risk of damage!

At the WPM II, set parameter 12 (source) in the

commissioning list to "Ethylene glycol", otherwise the

frost stat would stop the heat pump at temperatures

below 7 °C. The source inlet temperature can be

checked on the display of the WPM II under the Info

Temp. system parameter.

G

Temperature spread at nominal flow rate

C26_03_01_0834

A Brine = heating flow 35 °C

B Brine = heating flow 50 °C

T1 Temperature differential

T2 Source inlet temperature

8.4 Installation of the heat consumer system

8.4.1 Implement the heat consumer system (heating circuit)

in accordance with current technical rules. For safety equipment

in heating systems, consult the DIN EN 12828.

Protect the heating water lines against frost and moisture (only

in case of external installation). Protect flow and return lines

in external installations with an adequate amount of thermal

insulation against frost and by routing them inside a conduit

against moisture

(see Fig. D).

Maintain the required insulation thickness in accordance with the

Heating System Order [or local regulations].

The integral frost protection control (inside the heat pump), that

automatically starts the circulation pump in the heat pump circuit

at + 8 °C and thereby safeguards circulation in all water-bearing

components, offers additional frost protection. The heat pump is

started automatically no later than when the temperature inside

the buffer cylinder drops below + 5 °C.

Prior to connecting the heat pump, check the heating system for

leaks, flush it thoroughly, fill and carefully vent it.

When filling the system with heating water, observe VDI 2035,

sheet 1 [or local regulations]. In particular, this means that

— during the service life of the system, the total of the fill and

top-up water must not exceed three times the nominal volume

of the heating system,

— the total alkaline earths in the water must be < 3.0 mol/m³,

— the total water hardness must be < 3 mmol/l. Soften the water,

if the above conditions are not met.

Generally soften the heating water, if the specific system volume

> 20 l/ kW output (e.g. systems with buffer cylinder).

Ensure the correct connection of the heating flow and return.

Fit the thermal insulation in accordance with local regulations

appertaining heating systems.

8.4.2 Buffer cylinder

A buffer cylinder is recommended to ensure a trouble-free heat

pump operation. The buffer cylinder provides hydraulic separation

of the volume flow in the heat pump circuit and the heating circuit.

The flow rate in the heat pump remains constant if, for example,

the flow rate in the heating circuit is reduced by thermostatic

valves.

8.4.3 Circulation pump (cylinder primary pump)

When using a buffer cylinder, observe the pressure drop of the

evaporator, of the connecting lines, bends, valves etc. in sizing the

circulation pump to be installed.

8.4.3 Circulation pump (heating circuit pump)

Where no buffer cylinder is used, size the circulation pump on the

heating side taking the condenser pressure drop into consideration.

The flow rate at 'T = 10 K (see "Specification") of the heat pump

must be assured under all operating conditions of the heating

system through the installation of an overflow valve.

10 | WPF 20/27/40/52/66 www.stiebel-eltron.com

INSTALLATION

INSTALLATION

Loading...

Loading...