www.stiebel-eltron.com 13

Making the push-fit connection

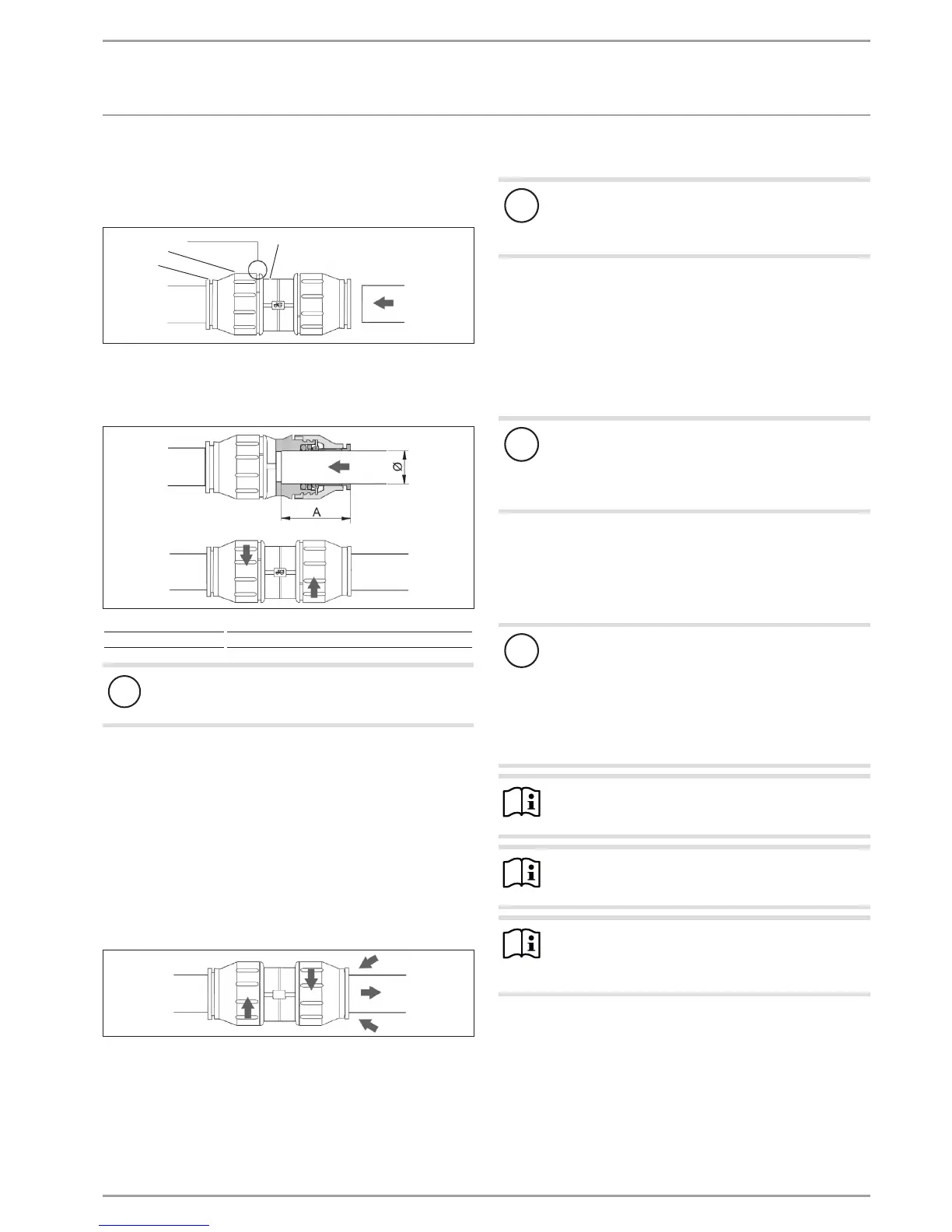

The connector must be in its relaxed position before the pipe is

inserted. In this position, there is a small gap between the screw

cap and main body.

26_03_01_0693

3

1

2

4

1 Retainer

2 Screw cap

3 Gap between screw cap and main body

4 Main body

26_03_01_0693

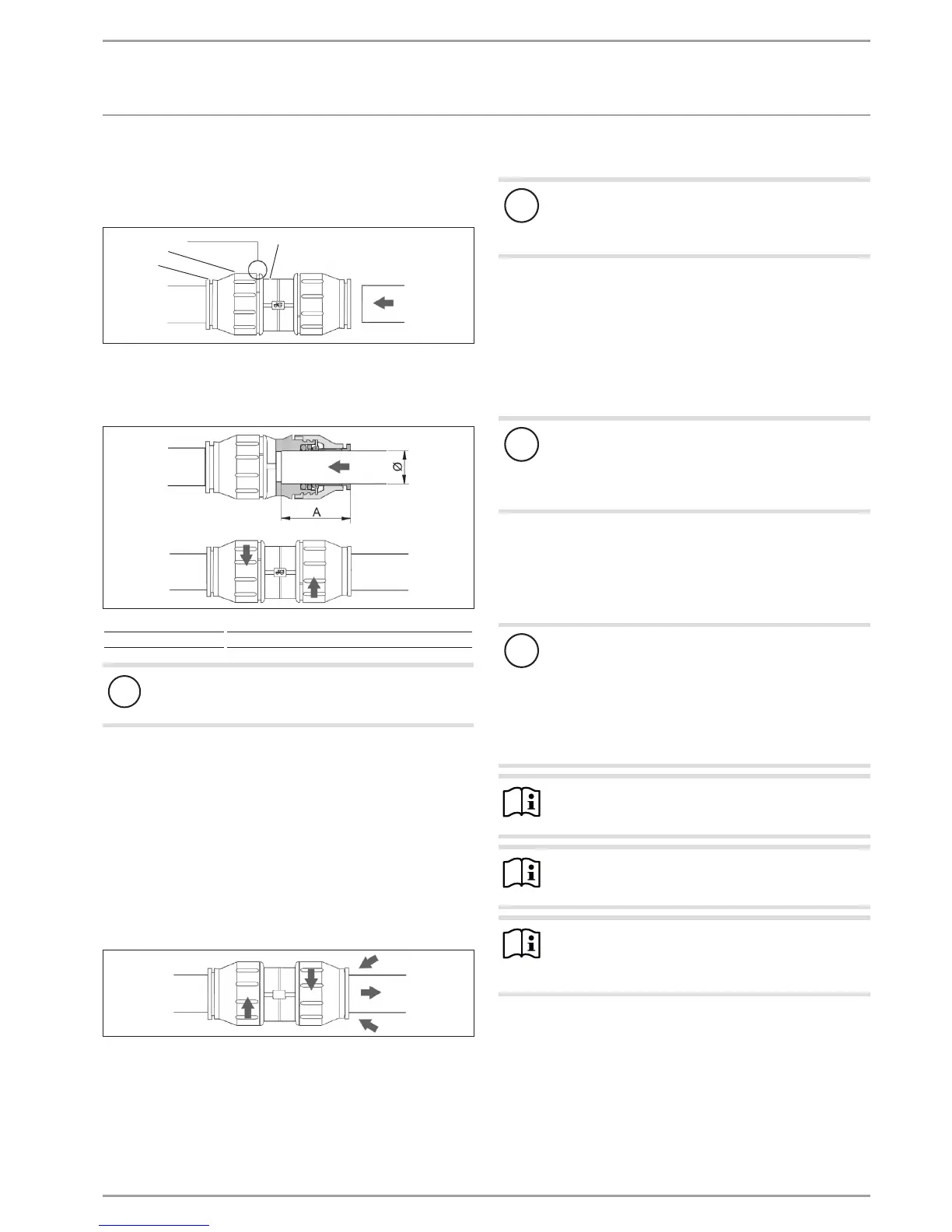

Pipe Ø 28 mm

Depth of insertion A 44mm

!

Material losses

Pipe ends must be deburred.

Always use a pipe cutter to trim pipes.

Push the pipe past the O-ring into the push-fit connector

until it reaches the prescribed insertion depth.

Tighten the screw cap by hand against main body as far as it

will go. This secures the push-fit connection.

Undoing the push-fit connection

If the push-fit connectors later need to be undone, proceed as

follows:

Turn the screw cap anti-clockwise until there is a narrow gap

of approx. 2mm. Press the retainer back with your fingers

and hold on to it.

Pull out the inserted pipe.

26_03_01_0693

10.5 Oxygen diffusion

!

Material losses

Avoid open vented heating systems and underfloor

heating systems with plastic pipes that are permeable

to oxygen.

In underfloor heating systems with plastic pipes that are per-

meable to oxygen and in open vented heating systems, oxygen

diffusion may lead to corrosion on the steel components of the

heating system (e.g. on the indirect coil of the DHW cylinder, on

buffer cylinders, steel radiators or steel pipes).

With heating systems that are permeable to oxygen, separate

the heating system between the heating circuit and the buff-

er cylinder.

!

Material losses

The products of corrosion (e.g. rusty sludge) can set-

tle in the heating system components, which may re-

sult in a lower output or fault shutdowns due to reduced

cross-sections.

10.6 Filling the heating system

Carry out a fill water analysis before filling the system. This analy-

sis may, for example, be requested from the relevant water supply

utility.

!

Material losses

To avoid damage as a result of scaling, it may be neces-

sary to soften or desalinate the fill water. The fill water

limits specified in chapter "Specification/ Data table"

must always be observed.

Recheck these limits 8-12weeks after commission-

ing, every time the system is topped up and during

the annual service.

Note

With a conductivity >1000μS/cm, desalination treatment

is recommended in order to avoid corrosion.

Note

If you treat the fill water with inhibitors or additives, the

same limits apply as for desalination.

Note

Suitable appliances for water softening and desalinating,

as well as for filling and flushing heating systems, can be

obtained from trade suppliers.

Fill the heating system via the drain (see chapter "Specifica-

tion/ Dimensions and connections").

After filling the heating system, check the connections for

leaks.

Loading...

Loading...