14 www.stiebel-eltron.com

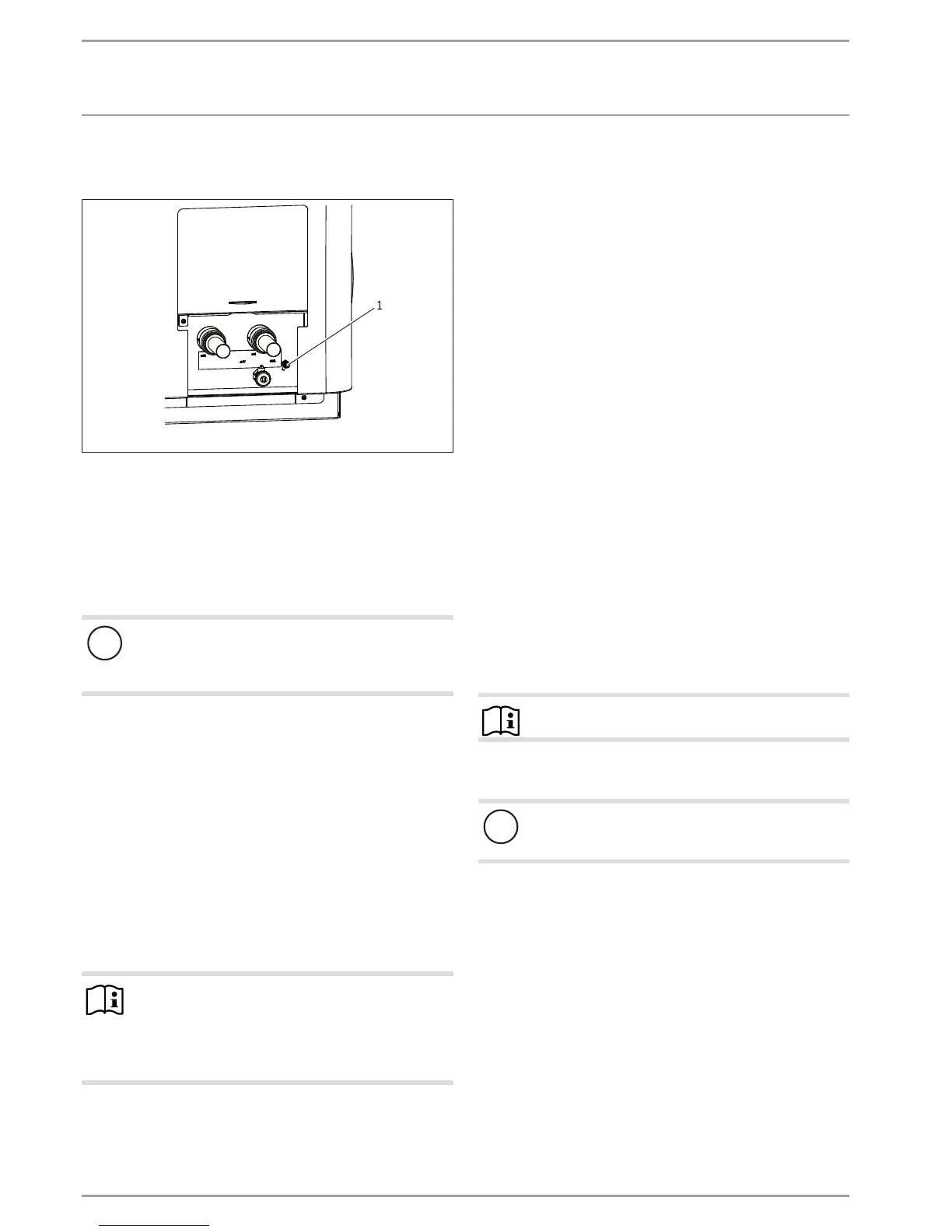

10.6.1 Venting the heating system

Vent the pipework carefully.

D000035306

1

1 Ventilation

Vent the pipework by activating the ventilation.

10.7 Minimum flow rate

The minimum flow rate and the defrost energy must always be

assured (see chapter "Specification/ Data table").

10.8 Setting the flow rate on the heating side

!

Material losses

For operation without a buffer cylinder, it is essential

that the electric emergency/booster heater (NHZ) is con-

nected.

The appliance is designed in such a way that no buffer cylinder

is required in conjunction with appropriately sized area heating

systems.

Installations with several heating circuits require a buffer cylinder

to be used.

The setting is made in heat pump mode. In order to do this, firstly

make the following settings:

Temporarily remove the fuse from the electric emergency/

booster heater to isolate the emergency/booster heater from

the power supply. Alternatively, switch OFF the second heat

generator.

Operate the appliance in heating mode.

In combination with the HM hydraulic module

Note

You can enable spread control in combination with the

HMhydraulic module (see menu “COMMISSIONING /

HEATING/ SPREAD CONTROL).

When spread control is disabled, the heat pump regulates

to the set pump rate and a fixed flow rate.

The flow rate is set automatically via the self-regulating system

(see menu "COMMISSIONING/ HEATING/ SPREAD CONTROL/

STANDBY PUMP RATE" in the heat pump manager).

In heat pump mode a fixed spread between the heat pump flow

and return is set (see menu "COMMISSIONING/ HEATING/ SPREAD

CONTROL" in the heat pump manager).

Checking the flow rate

Set parameter STANDBY PUMP RATE to 100%.

Set buffer operation to OFF.

If no buffer cylinder is installed, close all controllable heating

circuits.

The current flow rate can be called up in the menu "INFO/

INFO HEAT PUMP/ PROCESS DATA" under "WP WATER FLOW

RATE".

Compare the value with the specification (see chapter "Speci-

fication/ Data table").

If the specified flow rate is not met, take suitable measures

to achieve the flow rate.

If no buffer cylinder is installed, reopen all controllable heat-

ing circuits.

Reset the parameters to their original values.

10.8.1 Minimum flow rate with individual room control via

remote control in systems without buffer cylinder

For systems without a buffer cylinder, in the "SETTINGS/ HEAT-

ING/ STANDARD SETTING" menu, set the "BUFFER OPERATION"

parameter to "OFF".

In such cases, one or more heating circuits in the heating system

must be left open. Ensure the minimum flow rate (see "Specifica-

tion/ Data table") by means of the relevant open heating circuits

(see table "Sizing recommendation for the underfloor heating

system in the lead room").

Note

The table applies if individual room control is installed.

Sizing recommendation for the underfloor heating system in the

lead room:

!

Material losses

A buffer cylinder with diffusion-proof insulation is essen-

tial to enable cooling by means of fan convectors.

Loading...

Loading...