www.stiebel-eltron.com 11

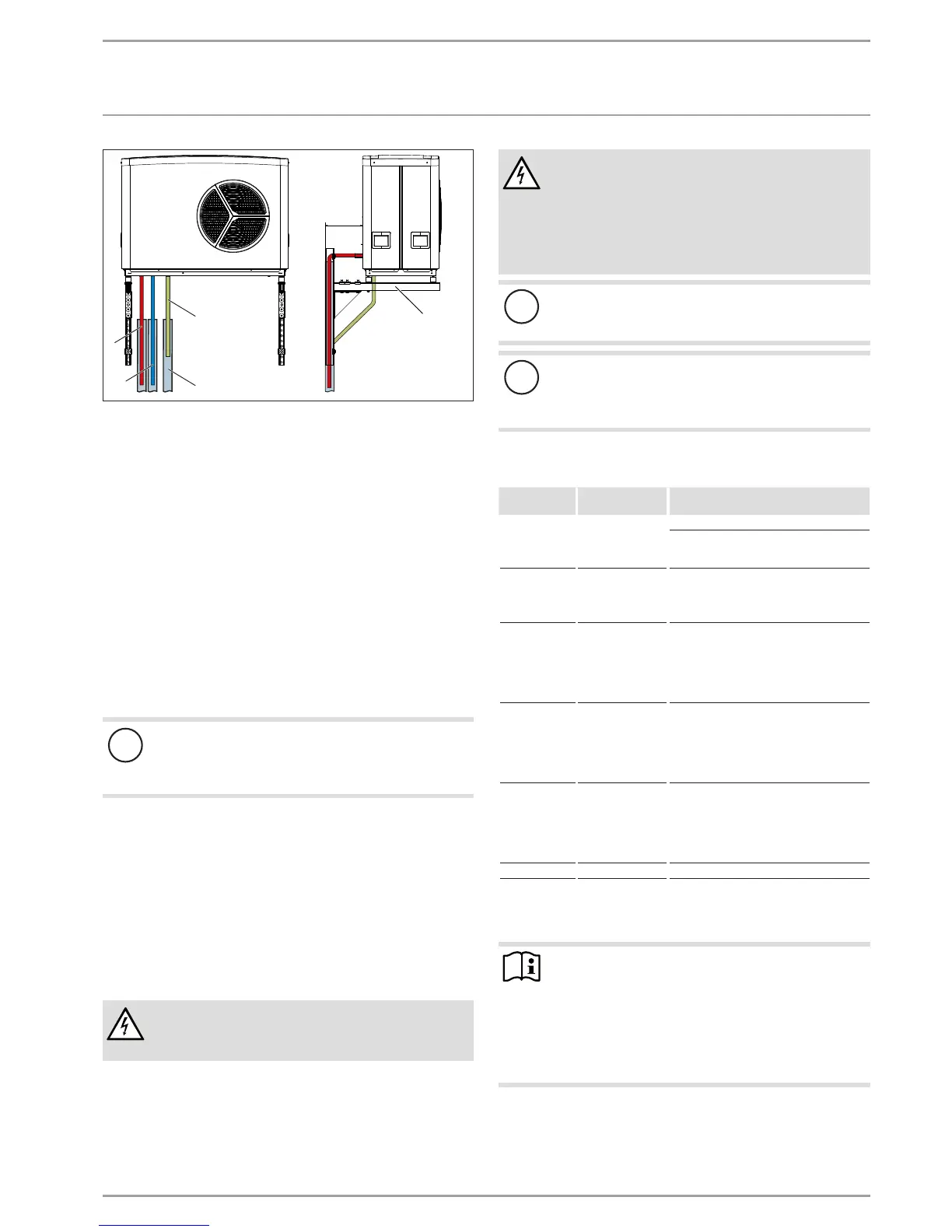

≥300

1

2

3

4

5

D0000058719

1 Heating flow

2 Heating return

3 Condensate drain

4 Condensate drain conduit

5 Wall mounting bracket

Observe the structural limits of the wall mounting bracket

used.

See the dimensioned connection drawing for the correct

spacing between holes (see chapter "Specification/ Dimen-

sions and connections").

9.6 WPM heat pump manager

A WPM heat pump manager is required to operate the appliance.

This controls the entire heating system.

Observe the WPM installation instructions during installation.

9.7 Buffer cylinder

!

Material losses

A buffer cylinder with diffusion-proof insulation is es-

sential to enable cooling by means of fan convectors. The

emergency/booster heater must be connected.

We recommend the use of a buffer cylinder to ensure trouble-free

appliance operation.

The buffer cylinder provides hydraulic separation of the volume

flows in the heat pump circuit and heating circuit, and also serves

as an energy source for defrosting.

For operation without a buffer cylinder, observe the details

in chapter "Minimum flow rate with individual room control

via remote control in systems without buffer cylinder".

9.8 Preparing the electrical installation

WARNING Electrocution

Carry out all electrical connection and installation work

in accordance with national and regional regulations.

WARNING Electrocution

The connection to the power supply must be in the form

of a permanent connection. Ensure the appliance can be

separated from the power supply by an isolator that dis-

connects all poles with at least 3mm contact separation.

This requirement can be met by contactors, isolators,

fuses, etc.

!

Material losses

The specified voltage must match the mains voltage. Ob-

serve the type plate.

!

Material losses

Provide separate fuses/MCBs for the three power circuits,

i.e. those of the appliance, the control unit and the elec-

tricemergency/booster heater.

Use cables with the relevant cross-sections. Observe the ap-

plicable national and regional regulations.

1x C 20 A

Compressor

(1-phase)

WPL 15 AS

WPL 15 ACS

2.5mm² when routing above the surface

4.0mm² when routing in a wall

1x C 35A

Compressor

(1-phase)

WPL 25AS

WPL 25ACS

6.0mm² when routing in a wall

3x C 16 A

Compressor

(3-phase)

WPL20A

WPL20AC

WPL25A

WPL25AC

2.5mm²

2x B 16 A

Electric emergen-

cy/booster heater

WPL15AS

WPL15ACS

WPL25AS

WPL25ACS

2.5mm²

3x B 16 A

Electric emergen-

cy/booster heater

WPL20A

WPL20AC

WPL25A

WPL25AC

2.5mm²

1x B 16 A Control unit 1.5mm²

The electrical data can be found in the chapter "Specification".

You require a screened J-Y (St) 2x2x0.8mm² cable as a bus cable.

Note

The appliance includes an inverter for the variable speed

compressor. In the event of a fault, inverters can cause

DC residual currents. If RCDs are provided, they must be

type B AC/DC-sensitive.

A DC residual current can block type A RCDs.

Ensure that the appliance power supply is discon-

nected from the distribution board.

Loading...

Loading...