59FS 240 C, FS 260 C, FS 360 C, FS 410 C, FS 460 C-M

After ending the test procedure,

disconnect the test lead and reseal

the diagnostic jack with the plug.

7.3.3 Check screwed and plug

connections as well as

switch

– Carry out test preparations,

b 7.3.1

There must be a reliable connection

for communication between control

unit, switching device and solenoid

valve. If communication between

control unit and solenoid valve is

interrupted or faulty, the control unit

does not initiate an ignition spark.

– In the event of a malfunction or if

there is no ignition spark, first

check the plug connections and

wiring harness between control

device and solenoid valve

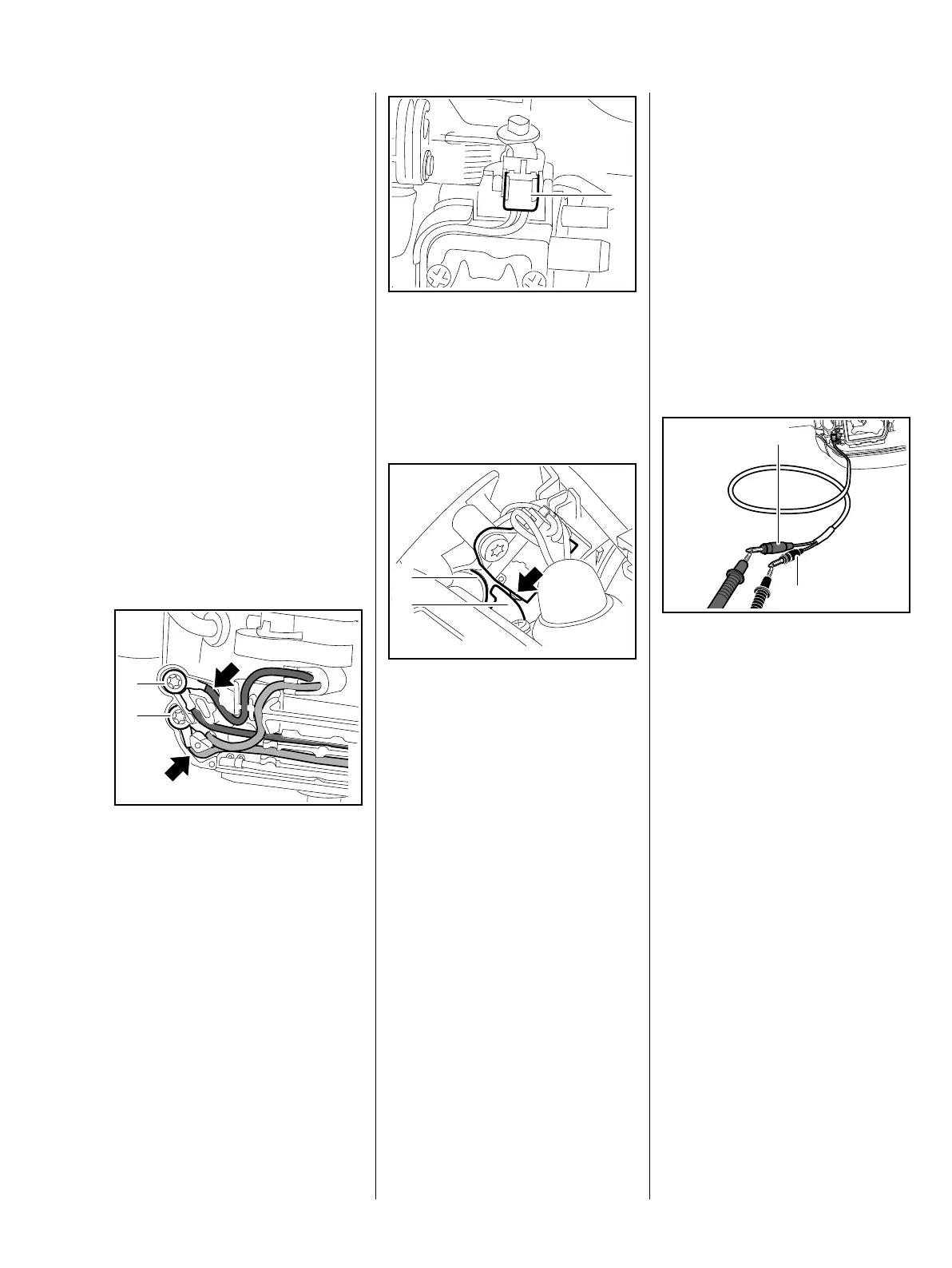

Screws (1) must be tight.

Leads (arrows) must be seated

completely and firmly in the cable

lugs.

1

5904RA277 TG

1

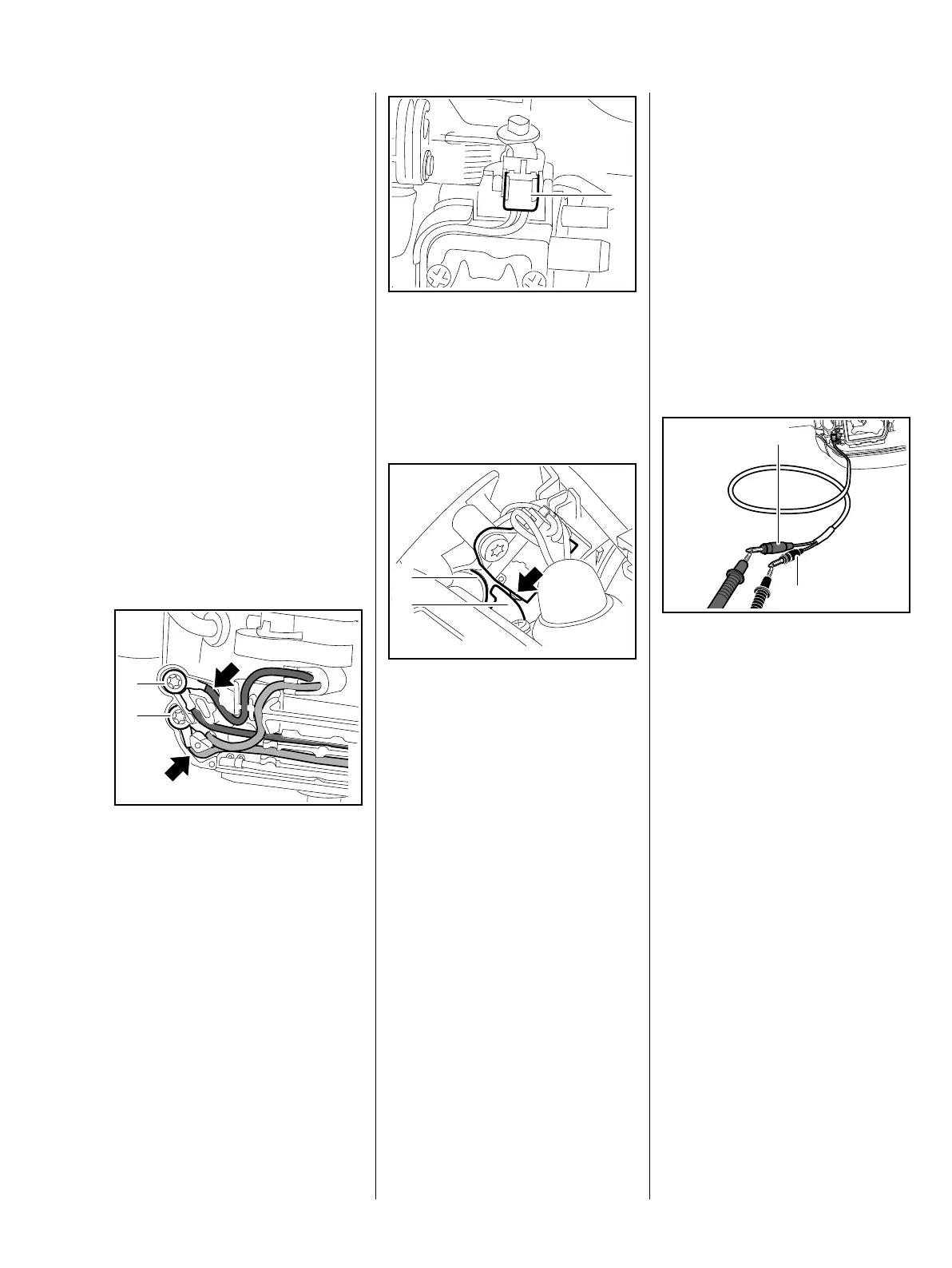

Plug (1) must be seated completely

and firmly in the recess of the

solenoid.

: If necessary, remove plug (1) and

check contacts

: Set choke lever (1) to

position }; the cam on the

lever (2) must actuate the

microswitch (arrow)

– Clicking noise

1

5904RA278 TG

2

5904RA279 TG

1

7.3.4 Checking the solenoid

valve

– Carry out test preparations,

b 7.3.1

– Check contacts and operation,

b 7.3.3

– Move choke lever to position "F"

– Connect the test lead, b 7.3.2

Measuring resistance

: Measure resistance between

plugs (1) and (2) of the M-Tronic

test lead

Target value: between 28 and

42 ohms

– If the target value is not attained,

check electrical leads for

interruption, e. g., due to cable

breakage between solenoid

valve and diagnostic jack

5904RA280 TG

2

1

Loading...

Loading...