31MS 210, MS 230, MS 250

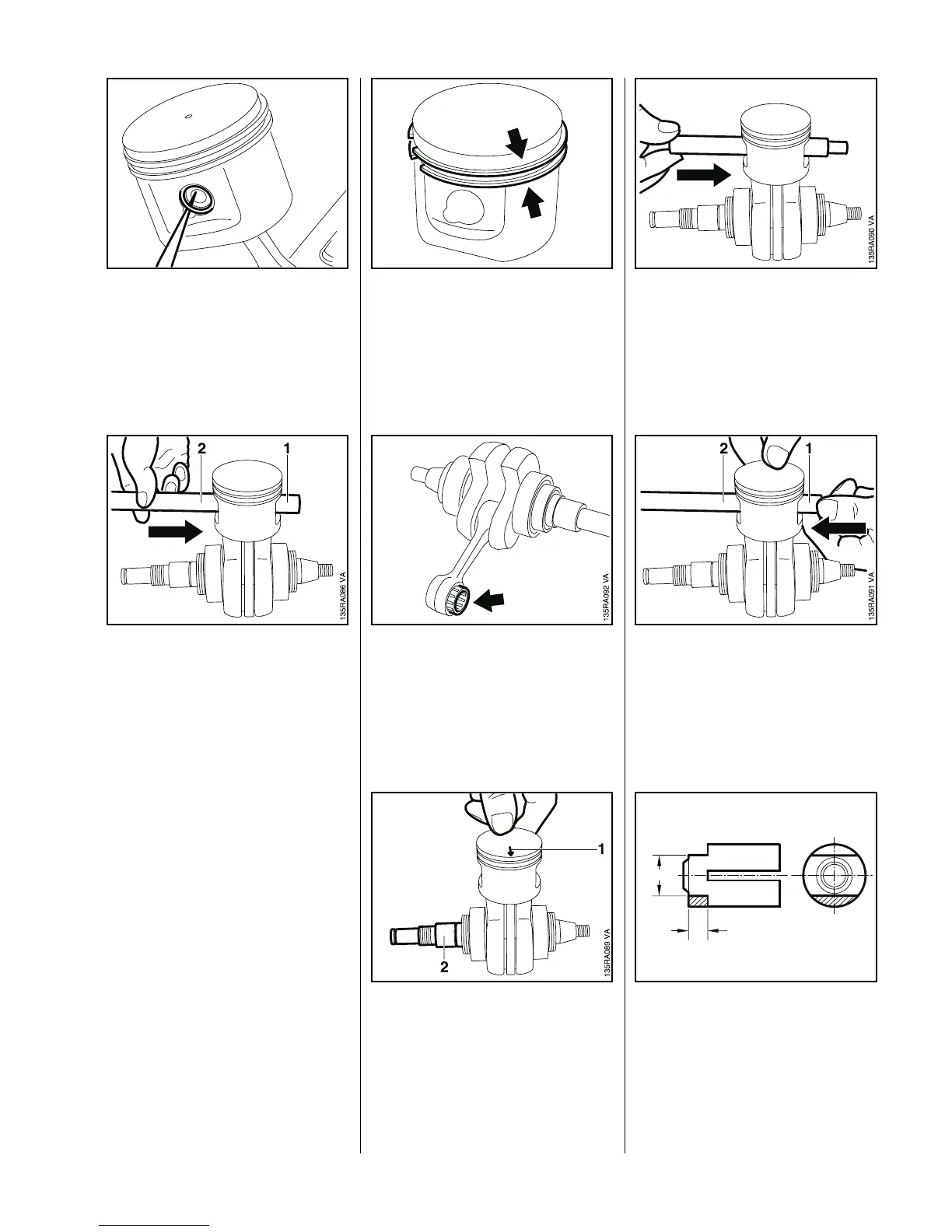

– Pull the piston out of the cylinder

– b 6.5.

: Ease the hookless snap rings out

of the grooves in the piston

bosses.

VA

135RA085

: Use the assembly drift (2)

1110 893 4700 to push the piston

pin (1) out of the piston.

If the piston pin is stuck, release it

by tapping the end of the drift lightly

with a hammer. Hold the piston

steady during this process to

ensure that no jolts are transmitted

to the connecting rod.

– Remove the piston from the

connecting rod.

– Inspect needle cage and replace

if necessary.

If needle cage is press-fitted,

replace the crankshaft.

: Inspect piston rings and replace if

necessary – b 6.7.

VA

135RA087

: Fit needle cage (arrow) in the

connecting rod (not MS 210).

– Oil the needle cage.

: To ease assembly, heat the

piston slightly and push it over

the connecting rod.

Installed position of piston:

1 = Arrow

2 = Long stub of crankshaft

: Push the assembly drift, small

diameter first, through the piston

and small end (needle cage) and

line up the piston.

: Fit the piston pin (1) on the

assembly drift (2) and slide it into

the piston (the pin slides home

easily if the piston is warm).

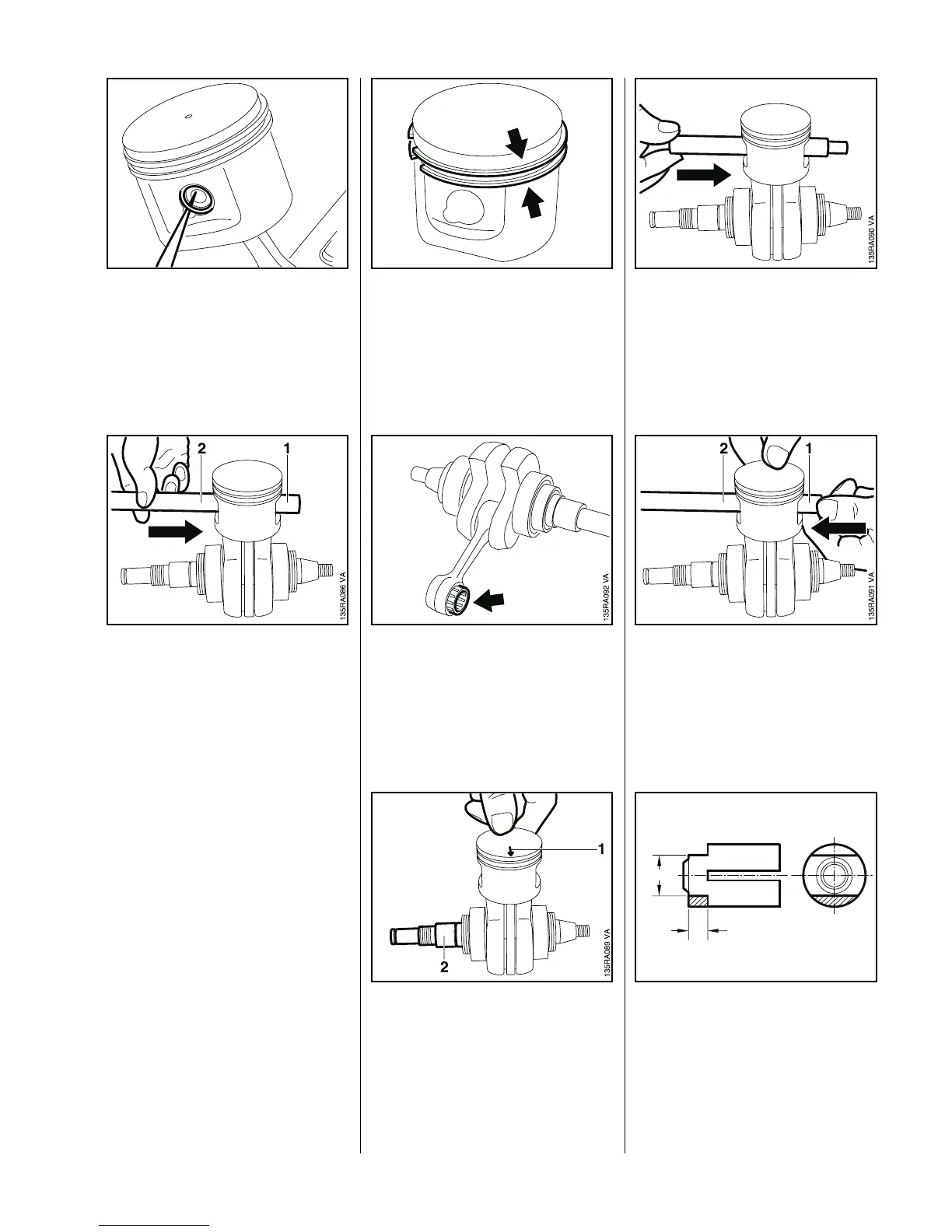

: Modify sleeve of the installing tool

5910 890 2210 as shown:

a = 16 mm (11/16")

b = 8 mm (5/16")

VA

135RA093

a

b

6.6 Piston

Loading...

Loading...