68 MS 210, MS 230, MS 250

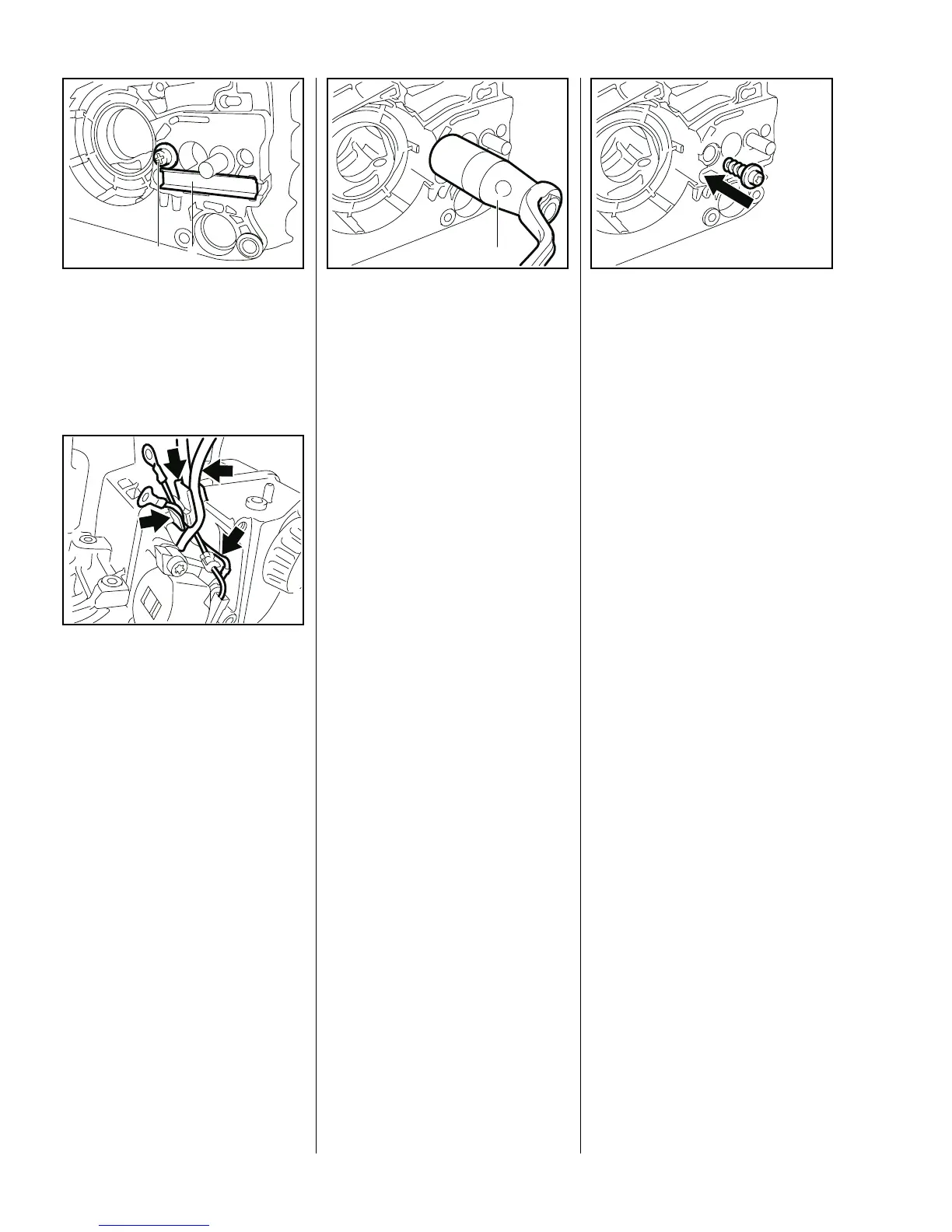

: On machines with quick chain

tensioner, remove the stiffener

(1) and take out the rear collar

screw (2).

VA

135RA229

2 1

Reassemble in the reverse

sequence.

: Position ground wires, short

circuit wire and ignition lead in the

housing slots.

– After assembling, set air gap

VA

135RA232

between ignition module and

flywheel – b 8.

– Coat the fuel hose flange with a

little oil to simplify installation.

– Straight side of hose flange must

be in line with the tank joint.

Replacement engine housings are

supplied with two collar screws of

the same length.

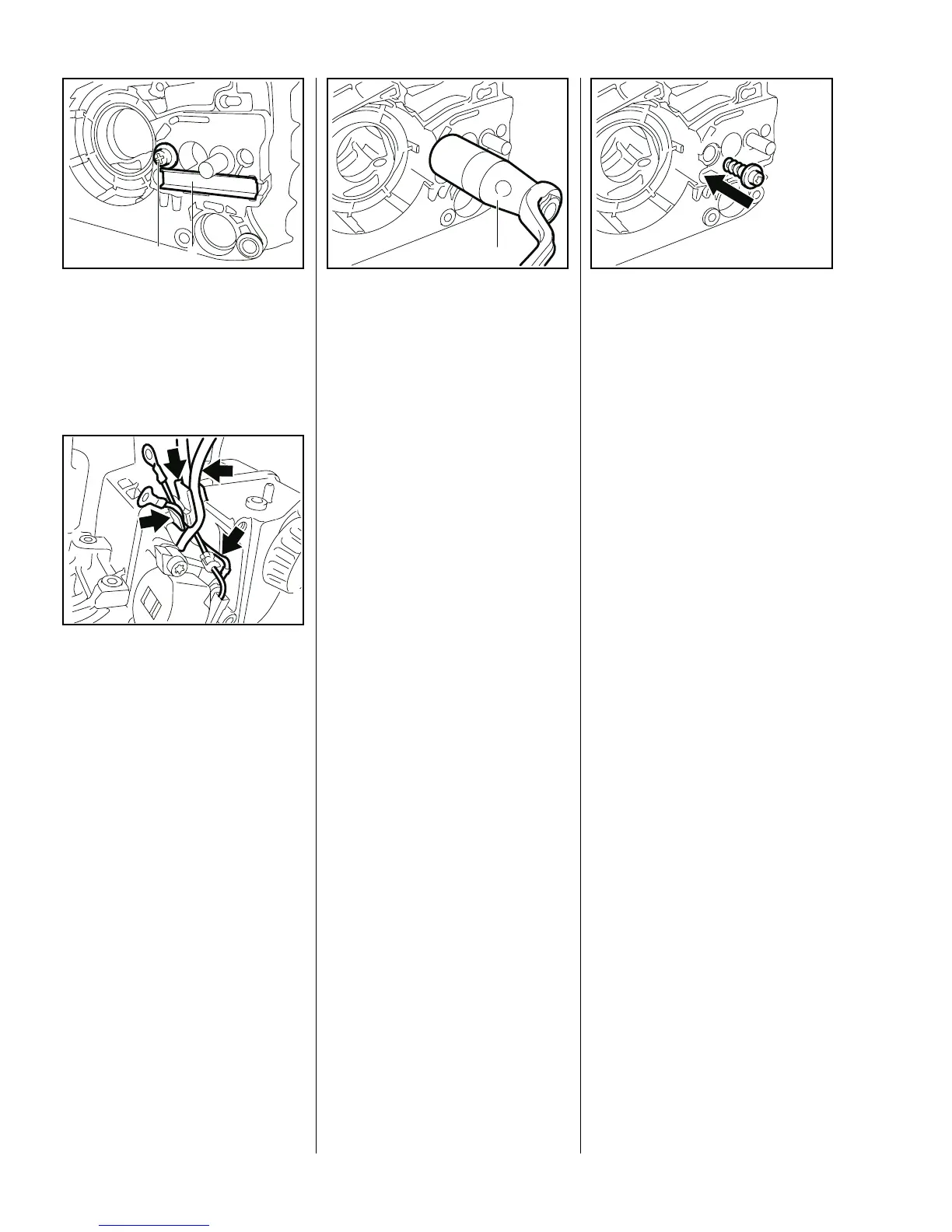

: To install engine housing in a

machine with a quick chain

tensioner, use stud puller (1)

5910 893 0501 to slowly unscrew

VA

135RA234

1

the rear collar screw.

Thread in engine housing can be

damaged if stud puller is turned too

fast.

– Apply a little oil to the thread of

the new or original collar screw.

: Insert collar screw in the bore of

the replacement engine housing

and turn it counterclockwise until

it engages the thread.

VA

135RA231

– Then screw it home clockwise

and torque down to about 8.0 Nm

(5.9 lbf.ft).

– Tighten down mounting screws

on spiked bumper to 3.7 Nm

(2.8 lbf.ft).

Reassemble all other parts in the

reverse sequence.

Loading...

Loading...