SG 31

English

9

Changing the Nozzle

A hollow cone nozzle (1) or fan jet

nozzle (2) can be fitted to suit

requirements.

Visual Inspection

Do not operate your unit if any of its

components are damaged. It is

particularly important to check the tank

and hose connection for leaks.

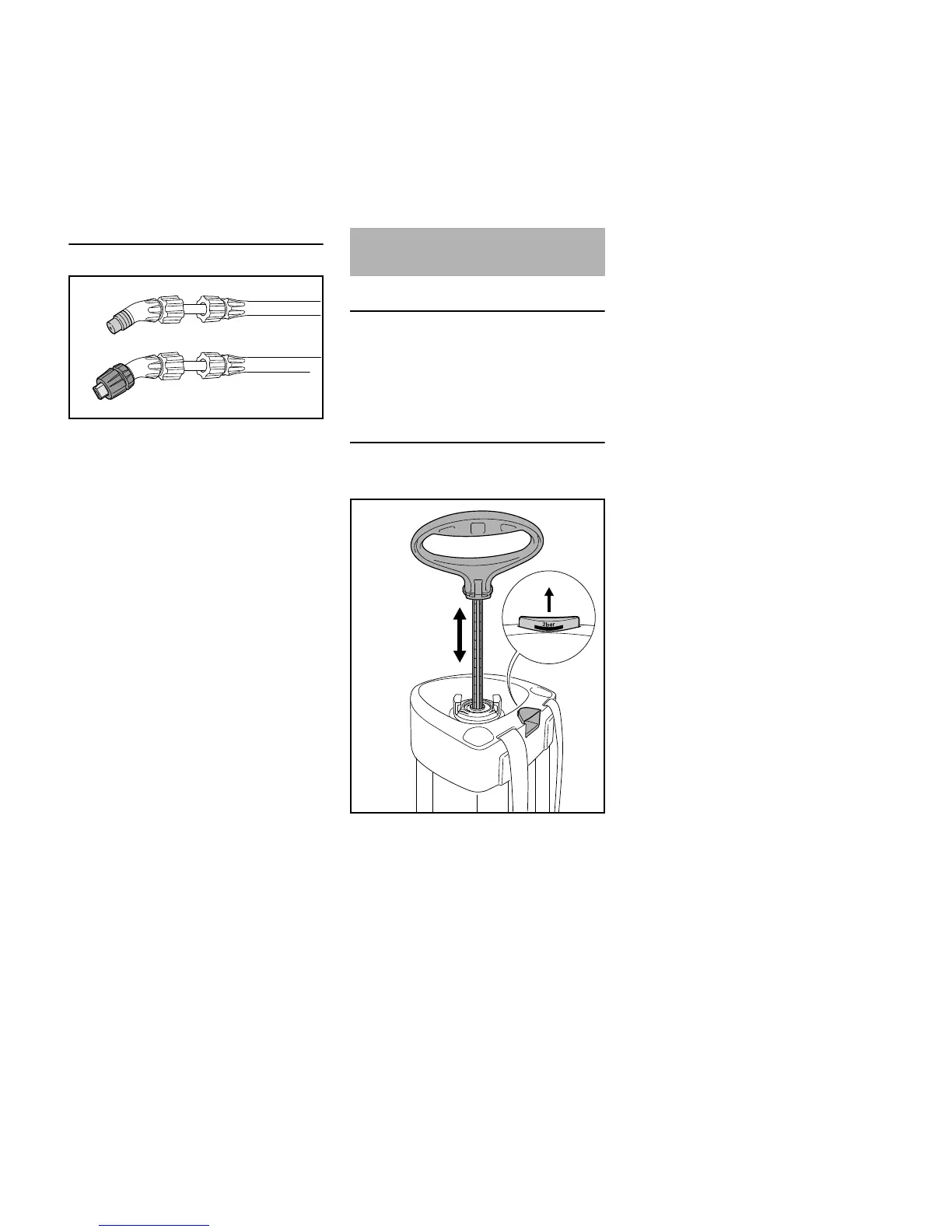

Checking for Leaks

Carry out test with the tank empty.

N Pressurize the tank – move the

unlocked pump handle (1) up and

down several times until piston

manometer (2) shows a pressure of

2 bar (29 PSI).

The pressure in the tank must not drop

any more than 0.5 bar (7.25 PSI) within

the next 30 minutes.

N Operate spray gun trigger –

pressure must escape.

N Release spray gun trigger –

pressure must not escape.

N Pull out piston manometer –

pressure must escape audibly.

N Completely depressurize the tank.

Loading...

Loading...