Remedying Faults in PP 1207–Klöckner Möller

Remedying faults PP 1207

page 38 –April 2005

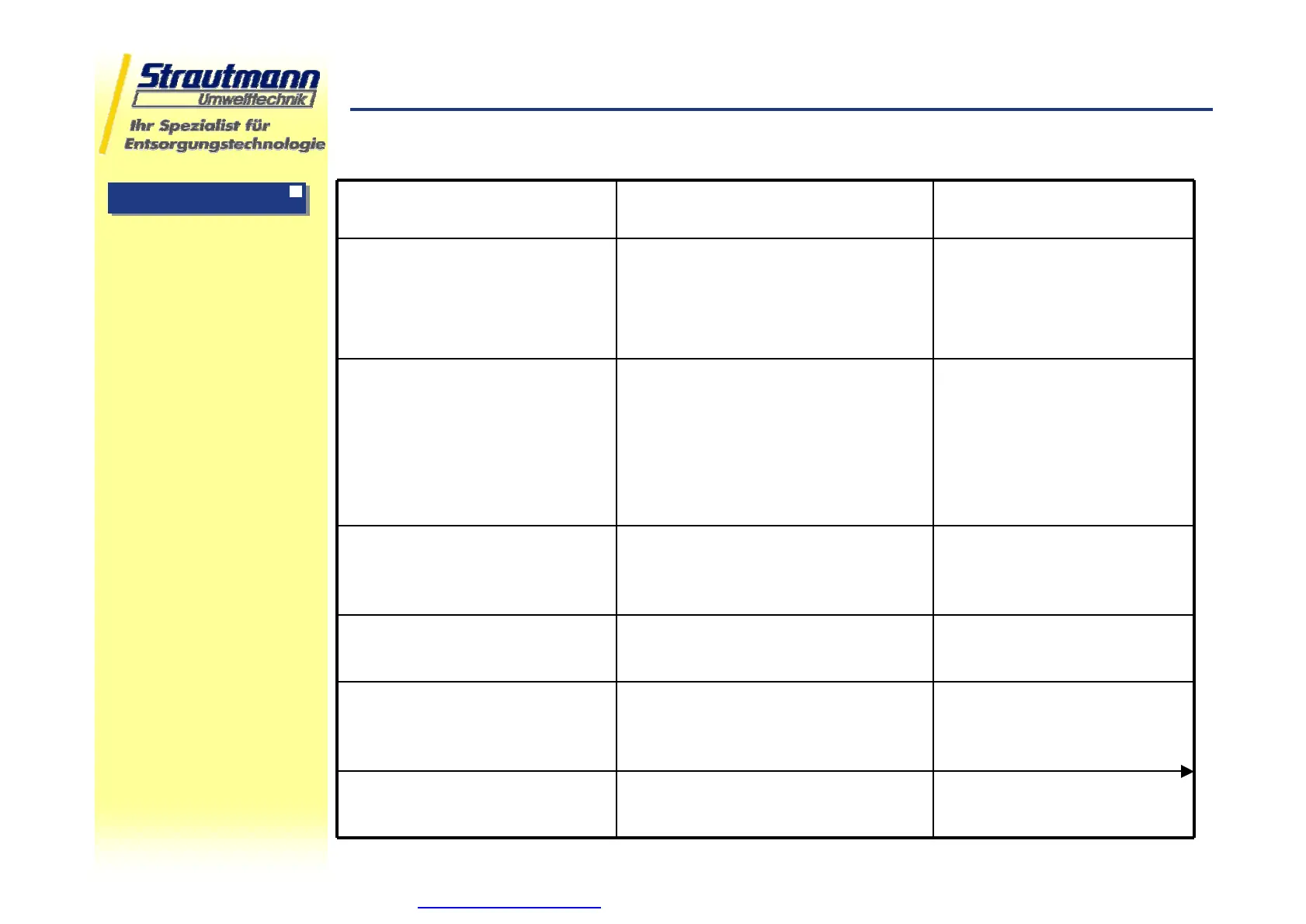

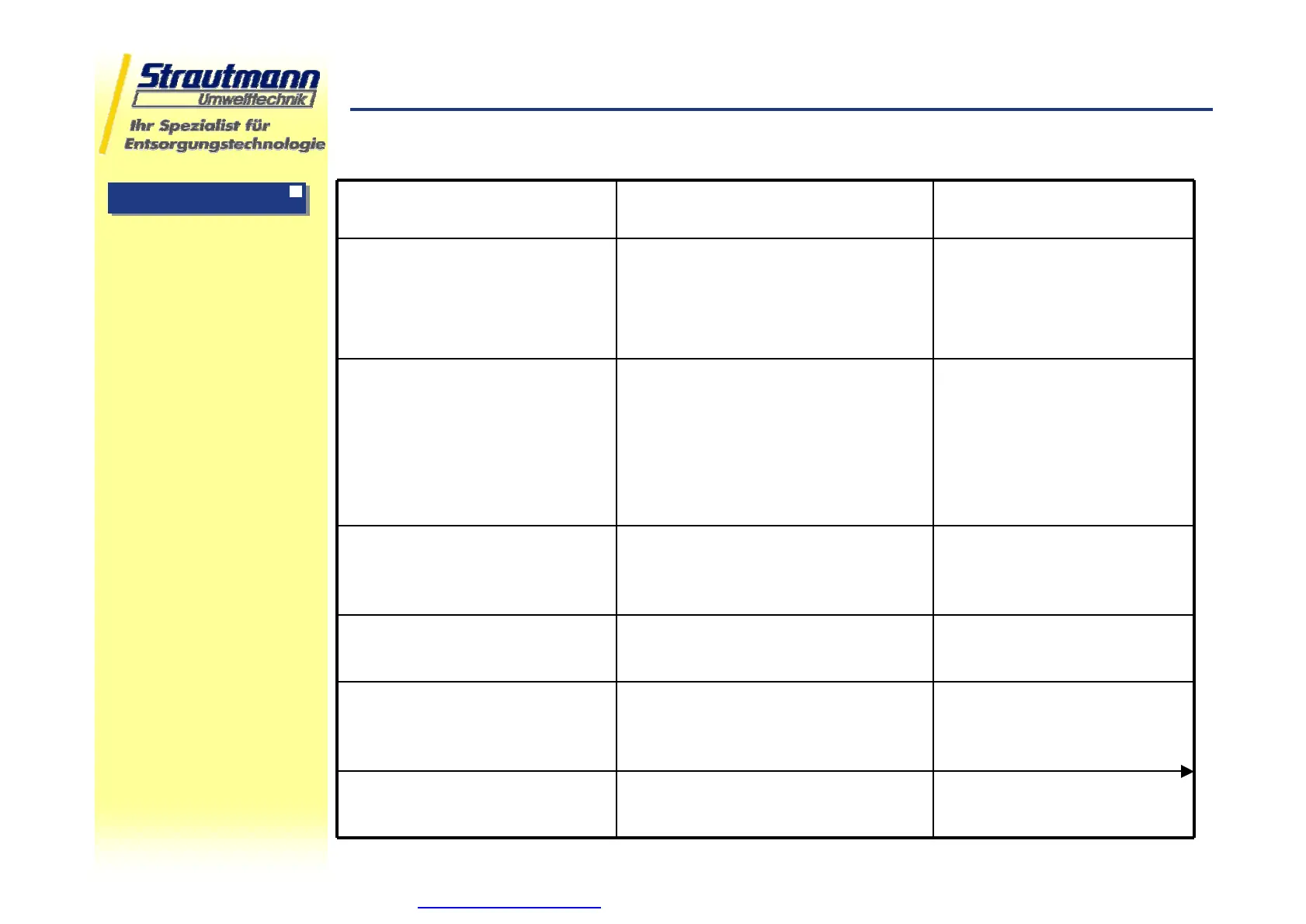

7. Hydraulic problems

Problem Reason Remedy

7.1 Machine does not

build up high pressure

A. Valve sticking, pressure

control valve faulty or

misaligned and pump faulty

Actuate valve manually,

check pressure control

valve, check pump and

replace if necessary

7.2 Machine running very

slowly and does high

pressure in the normal

range

A. Pressure sequence valve

and low-pressure pump both

faulty

Test DFV [pressure

sequence valve] and

replace if necessary

Test pump and replace if

necessary

7.3 Machine does

pressure vibrations while

moving down

A. Pressure sequence valve

faulty

Test valve and replace if

necessary

7.4 Weight of bale too

high or too low

A. Wrong pressure presets Check and adjust

pressures.

7.5 Machine “gags" during

pressing process

A. Pressure sequence valve

wrongly set or faulty

Adjust magnetic switch

and test, replace if

necessary

7.6 Motor reverses while

being switched off

A. Non-return valves faulty Replace valves

PDF wurde mit pdfFactory-Prüfversion erstellt. www.context-gmbh.de

Loading...

Loading...