3.4.2

STROBEL

Positions of the machine

General:

C A U T I 0 N ! Danger of injury!

Danger

of

crushing fingers and needle

through

stitching

as

well

as pulling in

of

parts

of

clothing.

Keep fingers and hands

away

from

moving

parts

when

setting

the

position

generator

and checking

the

positions

with

switched-on

machine.

Stop

motors

require a position generator,

which

takes

the

mechanical

setting

of

the

machine

from

the

main

screw

and

transmits

this

to

the

control

of

the

motor.

(fig. 2)

The

correct

position

of

the

position generator

to

the

flange is marked

with

a

spot

of

paint.

To

adjust

or

to

remove, release

the

two

clamping

screws

(2), fig. 2.

tighten

these

firmly

prior

to

commissioning.

Machine with

or

without hold-back device:

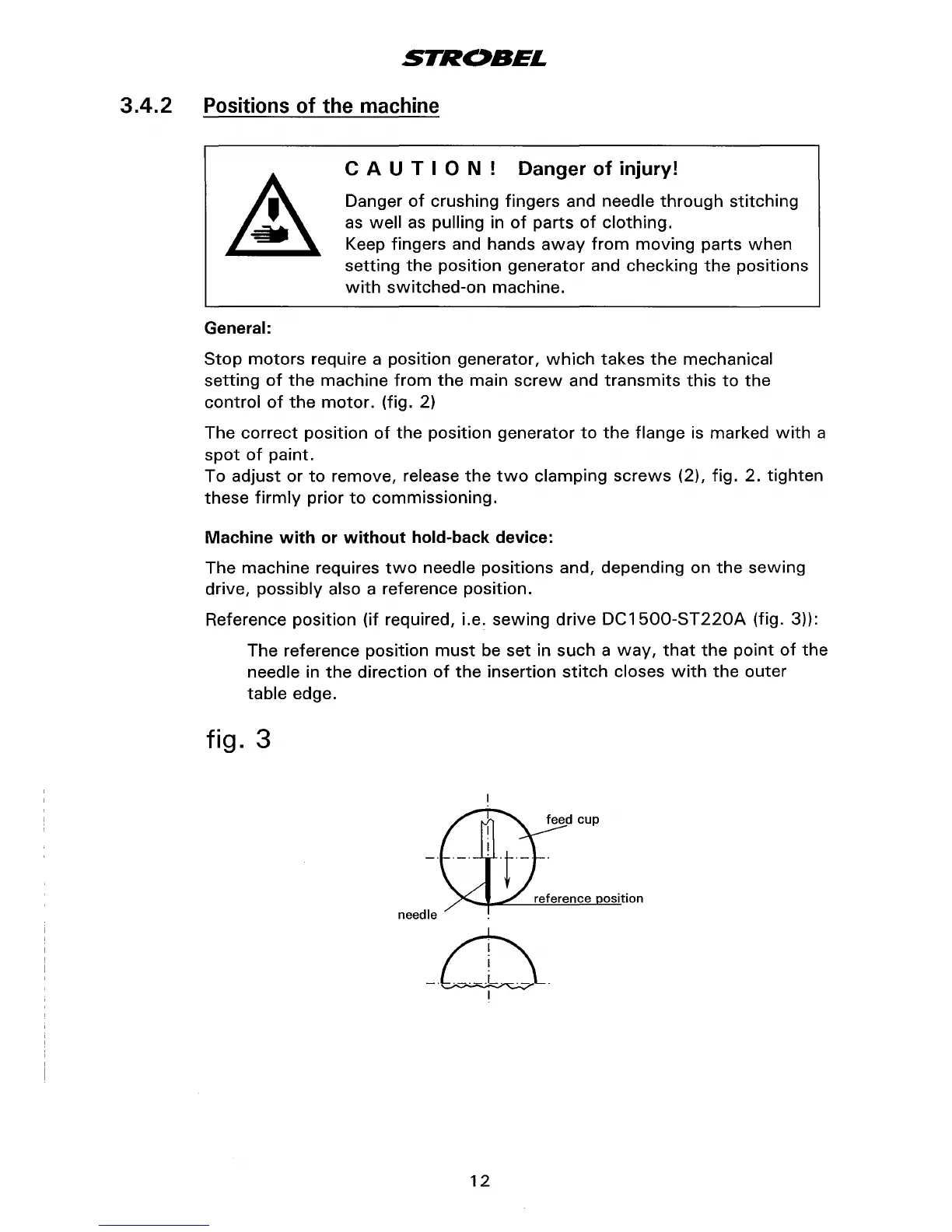

The machine requires

two

needle positions and, depending on

the

sewing

drive,

possibly

also a reference position.

Reference

position

(if required, i.e.

sewing

drive

DC1500-ST220A

(fig. 3)):

The reference position

must

be

set

in

such

a

way,

that

the

point

of

the

needle in

the

direction

of

the

insertion

stitch

closes

with

the

outer

table edge.

fig. 3

needle

12

Loading...

Loading...