- 25 –

8 COMMISSIONING

8.11 System check: Ensure that the electrical supply to the pump is switched off

before opening the mains water supply stopcock and checking for leaks.

8.12 Check vessel pre-charge pressure:

It is important to have the correct pre-charge pressure in the vessel for your

site conditions to optimise performance. The vessel is supplied with a

pre-charge pressure of approximately 1.4 bar, and should never have a preset

pressure of less than 0.5 bar.

Checking and adjustment to the vessel pre-charge air pressure can only be

carried out when the vessel is empty (contains no water).

8.13 Check mains static pressure:

z Now close outlets and check pressure gauge after ‘Y’ strainer – for static

mains pressure and note it. This should be done at peak times of use.

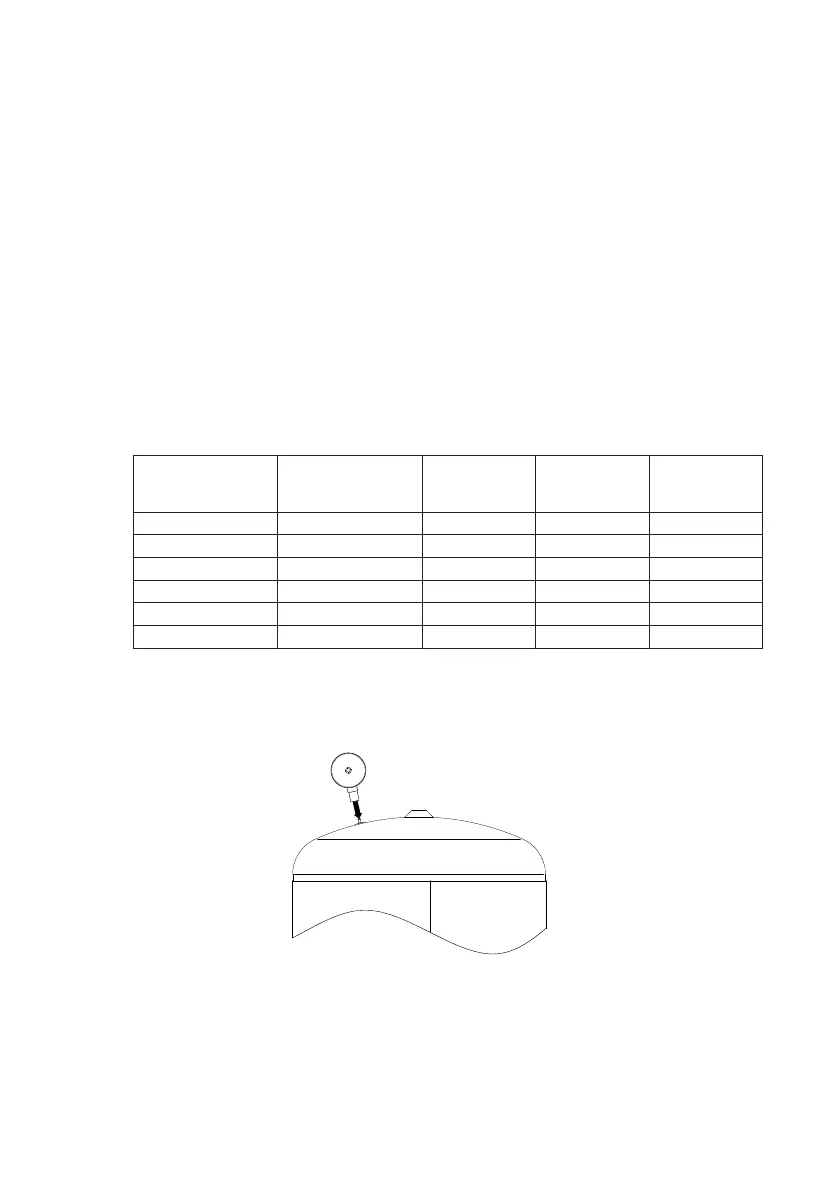

z Turn stopcock off and leave outlet taps open.

8.14 Check the chart below for the correct vessel pressure against the static mains

pressure recorded.

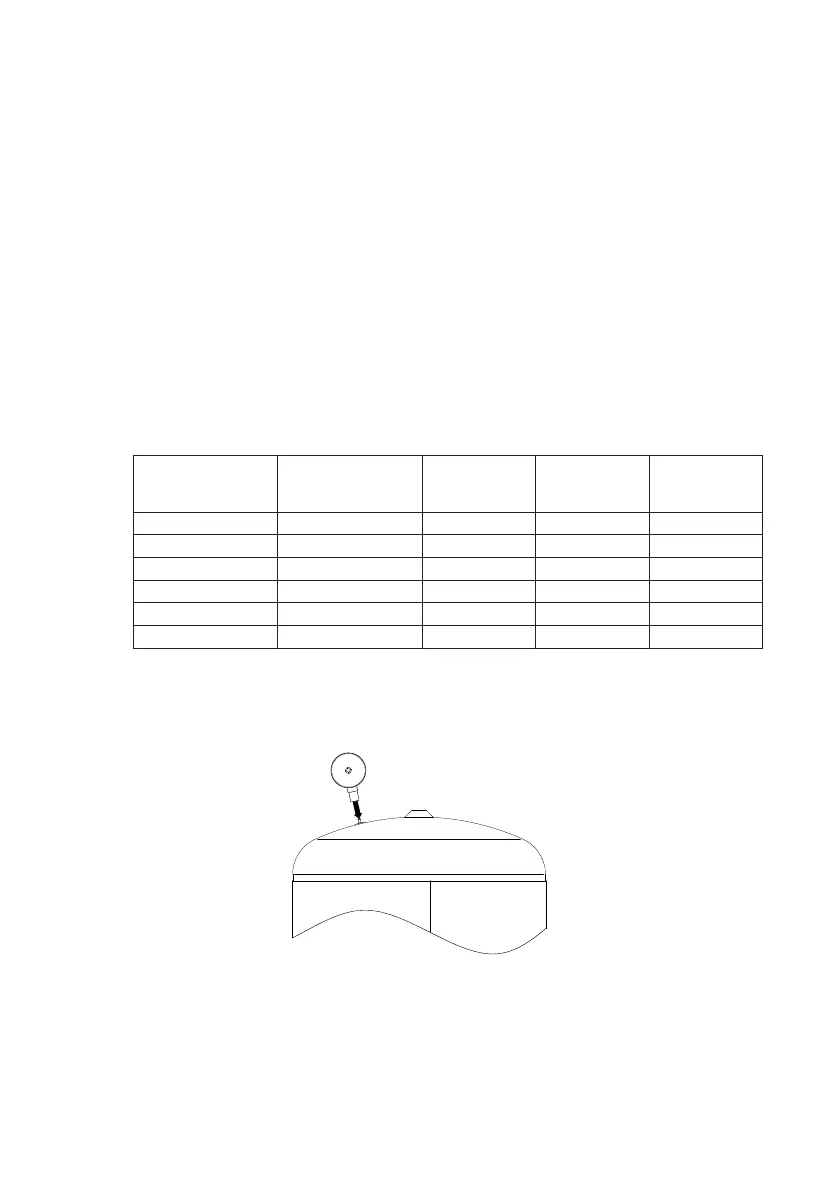

Using a pressure gauge check the vessel and adjust to suit through the

schrader valve.

Warning: NOTE PRV setting must not exceed 5.0 bar.

MJ3 pump max.

set pressure

Static mains

pressure

Set vessel

pre-charge

pressure to

Differential

Set PRV

maximum

setting to

bar bar bar bar

3 bar 1.0 1.2 1.8 1.0

3 bar 1.5 1.2 1.8 1.5

3 bar 2.0 1.2 1.8 2.0

3.5 bar 2.5 1.7 1.8 2.5

3.5 bar 3.0 1.7 1.8 2.5

Fig. 28

Loading...

Loading...