- 14

-

5. COMMISSIONING / SYSTEM FLUSHING / PRIMING / STARTING

5.1. System Flushing: The pipework system should be flushed out prior to the pump

being connected to ensure any contaminants / chemical residues and foreign

bodies are removed from elsewhere in the system.

5.2. Water Supply: Always ensure that water storage capacity is adequate to meet

the demand. Ensure the pump chamber is full of water before starting the

pump. Failure to do this could result in seal damage. To ensure dry running does

not occur the pump must be primed as described in priming section below. Do

not run pump dry. The volume ratio of solid impurities in the medium should not

exceed 0.1%, and the particle size should not exceed 0.2mm diameter.

5.3. Priming:

Never operate pump with inlet and/or outlet isolating valves in the closed position.

Damage will occur!

The pump must be primed (filled with water) before starting. Turn on the service

valves and vent/prime pump head.

a) Loosen priming plug and allow an even flow of water, this may take a few

seconds.

b) Re-seal draining plug, nipping tight. The pump is now ready to start.

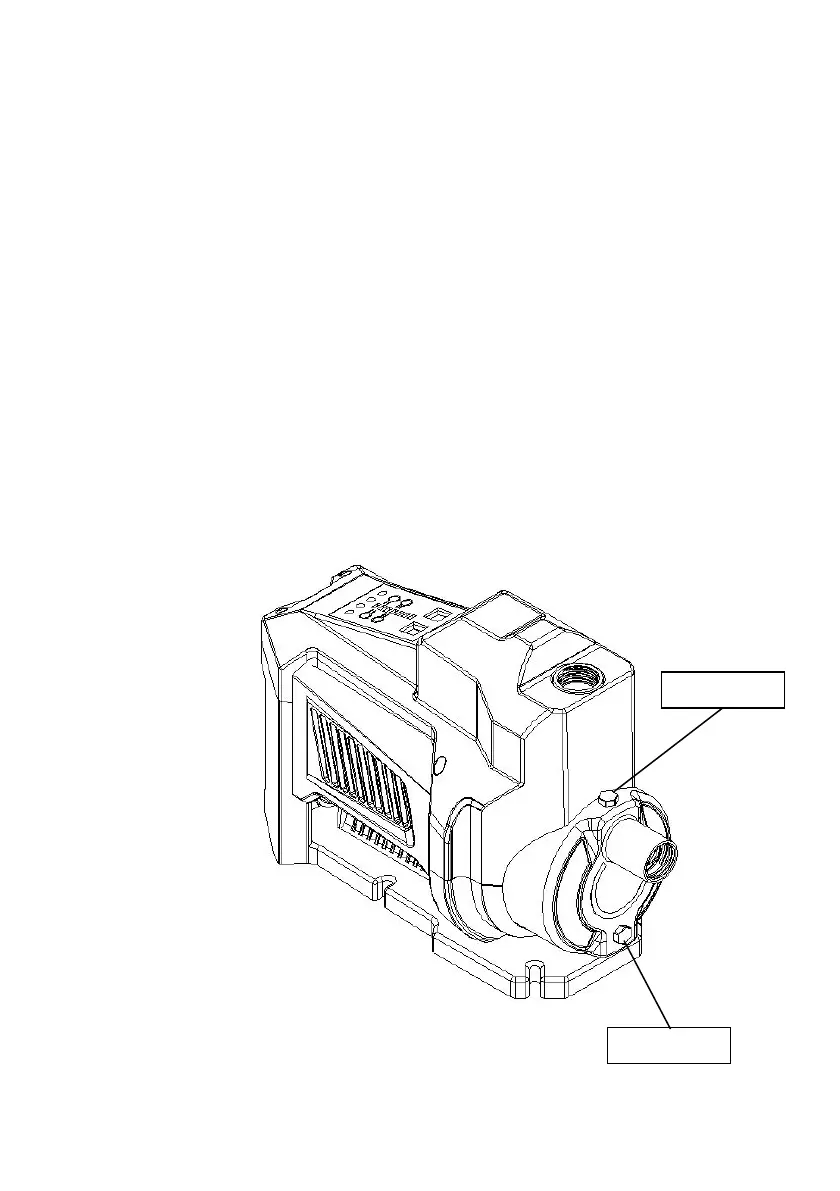

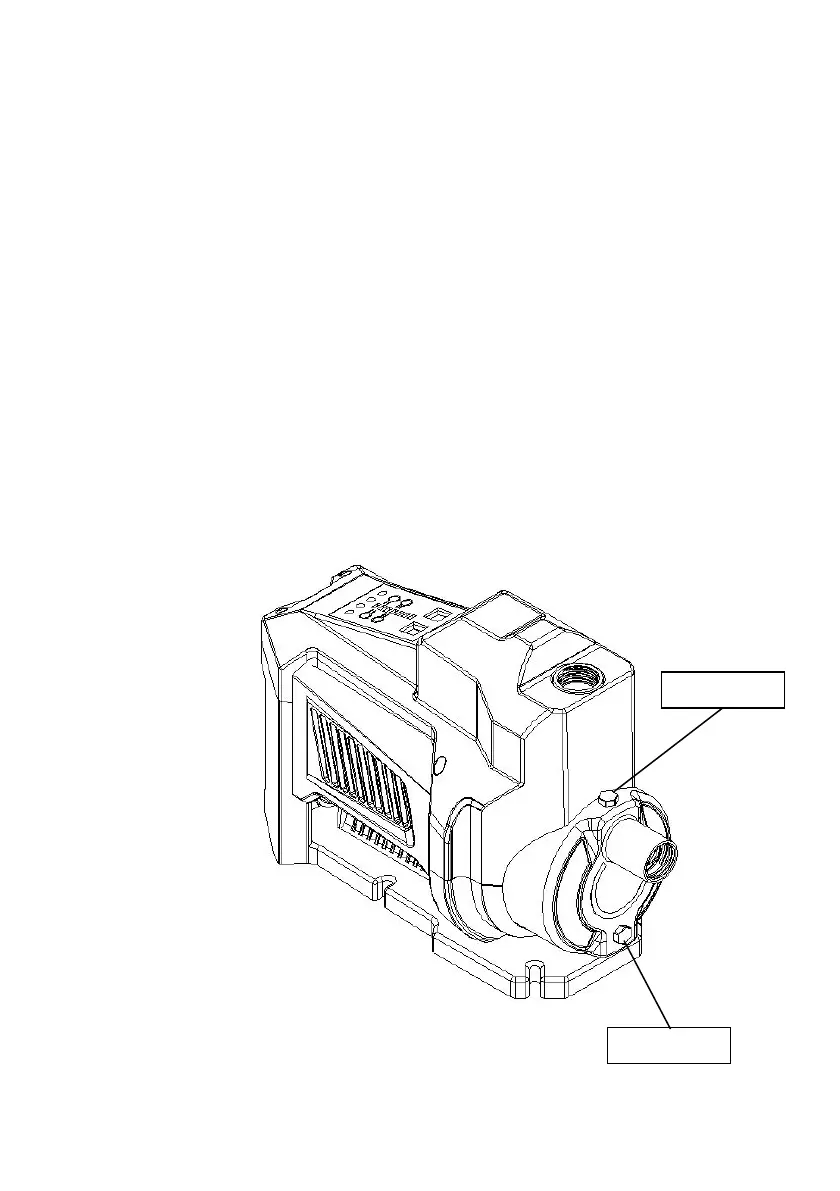

Fig 5.

Mainboost VariQ.

Loading...

Loading...