(© Aug, 2006)

Compact CWE Series Installation, Operation & Maintenance Manual

2-2

2.2 Site Preparation

Compact CWE systems are designed with easy

service access in mind. Component access panels are

located on the front of the equipment. The number of

panels may vary depending on size and configuration.

Each unit has one front hinged access panel housing

the electrical box. In order to have full service access

through the front of unit, no permanent obstructions

can be placed in front of the unit. (See Figure 1.)

NOTE

Working clearance requirements need to be es-

tablished prior to mounting the unit. Refer to lo-

cal and national electrical codes.

To minimize the effects of the conditions surrounding

the conditioned space, certain steps must be taken.

This is especially true for critical/precision room

preparation (computer rooms/labs) requiring a close

tolerance of temperature and humidity variation. The

conditioned space should be well insulated and

include a vapor barrier. The installer should ensure that

the proper insulation rating is used based on the

design of the space, which was the basis for the

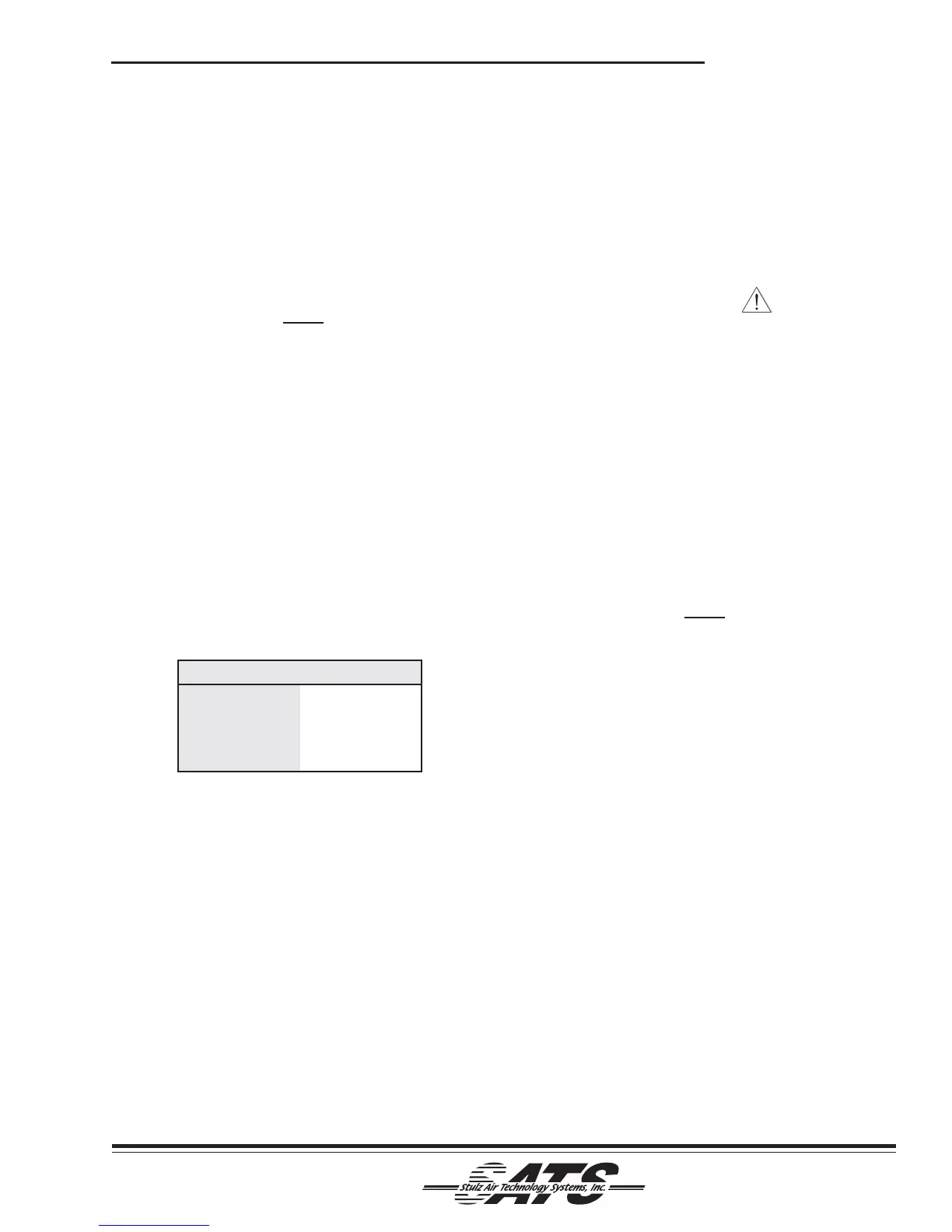

system selected. The following chart is a recom-

mended minimum R-value (thermal resistance) to

ensure optimum equipment operation.

The vapor barrier is the single most important require-

ment for maintaining environmental control in the

conditioned space. The vapor barrier in the ceiling and

walls can be a polyethylene film. Concrete walls and

floors should be painted with a rubber or plastic based

paint. Doors and windows should be properly sealed

and a door sweep used to minimize leakage. Outside

or fresh air should be kept to a minimum (because it

adds to the cooling, heating, dehumidification and

humidifying loads), while still maintaining the require-

ment of the Indoor Air Quality (IAQ) standard. Lack of

attention to these factors can cause erratic operation,

unstable room control and excessive maintenance

costs.

2.3 Rigging

The Compact CWE systems are designed to be kept

in a vertical position. Move the unit with a suitable

device such as a forklift, pallet jack or roller bar and

dollies. Weight tables are provided on the installation

drawings. Units are shipped on a skid to facilitate

moving prior to installation. Units should always be

stored indoors in a dry location prior to installation.

CAUTION

Units must be kept level and in the vertical posi-

tion when lifting to prevent damage to the unit.

2.4 Mounting/Placement

Compact CWE systems that are not ducted are

designed to be located in the conditioned space.

Ducted units may be located inside or outside the

conditioned space, but are designed to supply air to

only one room. Compact CWE systems are front

accessible, which allows the units to be placed in a

corner or between cabinetry. It is recommended that

the unit is positioned in order to optimize air circula-

tion.

NOTE

Placement of the floor or ceiling registers is im-

portant. If they are too close to the unit, the sup-

ply air will be recirculated back to the unit be-

fore it has circulated throughout the space.

The downflow air pattern A/C unit has been designed

to be located directly on a raised floor. On some raised

floor installations, a floor stand is required, depending

on the load capacity of the existing raised floor. (See

Figure 2).

2.4.1 A/C Unit

The Compact CWE system uses a frame and panel

construction for unit rigidity and full service accessibil-

ity without moving the unit. Ensure the mounting

surface is able to support the weight of equipment.

Before mounting the unit, refer to the weight tables

that are provided in the installation drawings.

If a floor stand is used, refer to the installation drawing

provided and cut out the raised floor to match the

unit’s overall base dimension. If a floor stand is not

used, cut out the raised floor to match blower dis-

charge opening(s) and any required piping and wiring

holes. Refer to the installation drawing supplied with

the unit for dimensional information.

STRUCTURE R-VALUE

Ceiling R-38

Wall R-21

Floor R-19

Door R-5

Loading...

Loading...