68 EN/39B/06.2018 © STULZ SpA – all rights reserved

SAL

Filling with refrigerant (when necessary)

If distance covered by refrigerant lines is more than 5 m, refrigerant must be added. This operation

must be done after completing installation and start-up of the unit. While compressor is running,

connect the charge cylinder to the low pressure (suction) gas side of compressor and fill with the

right quantity as per table 1.

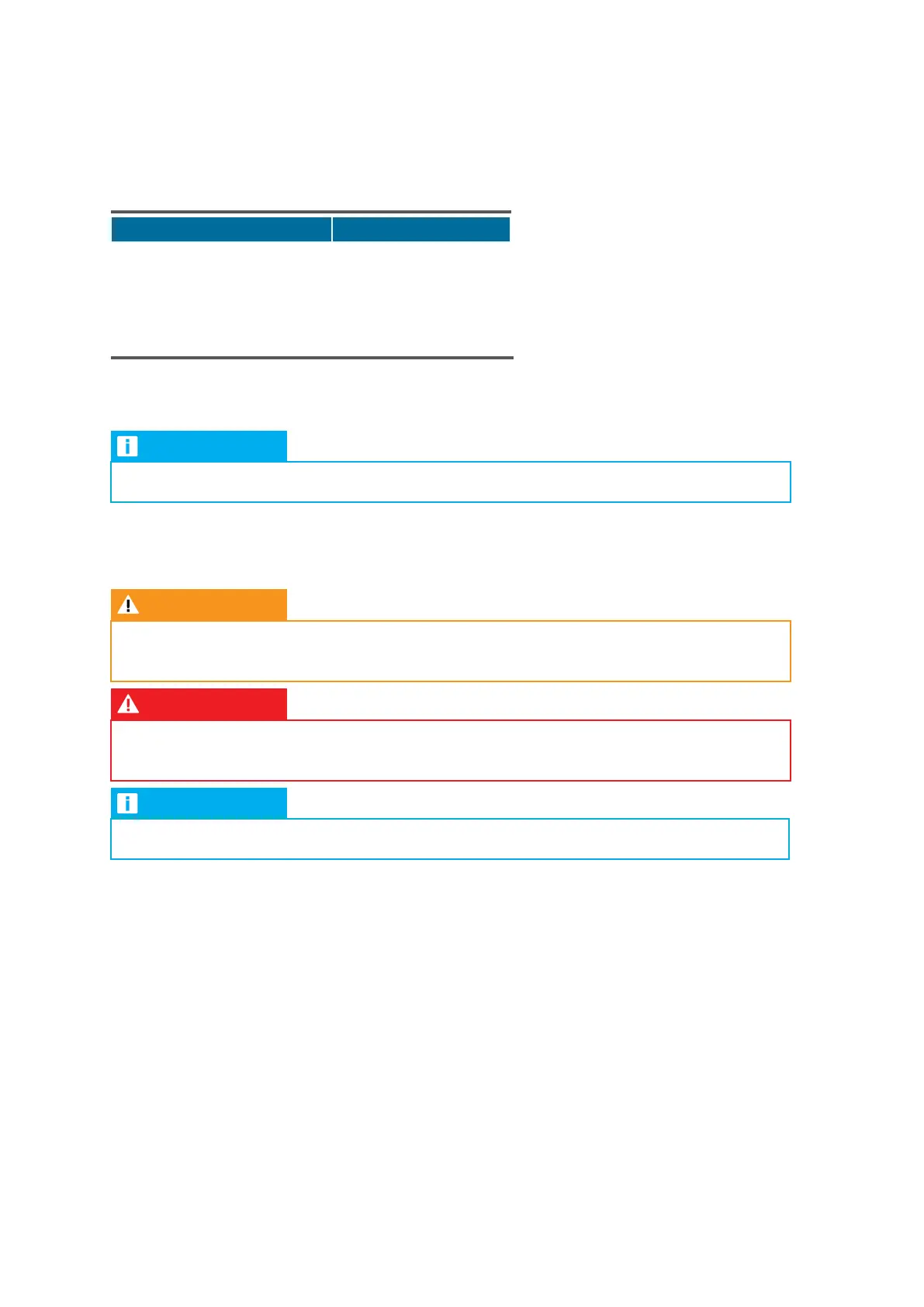

Gas/liquid pipe ext. diameter [mm] R134a additional charge [g]

10; 12 2,7 d

16 5,2 d

18 6,6 d

22 11 d

28 19 d

TABLE 1: Additional charge of R134a refrigerant for piping distance beyond 5m (maximum 30 m).

Values applying with condensation T = 50°C

INFORMATION

In this table d = distance (measured in meter)

11.7. Soft start for three-phase compressor – SOFTT

DANGER

Hazardous voltage: will cause death or serious injury. Disconnect power before working on

equipment.

ATTENTION

Setting of this component is made in factory and shown in the wiring diagram. Before altering it,

contact STULZ service.

INFORMATION

With SOFTT option, the working limit of the unit is 45°C external temperature.

The soft start is installed inside the e-box on the supply line to the compressor. Its purpose is the

reduction of compressor starting current. This can be obtained in two ways:

• Soft start is the most common method of starting. The initial torque setting is DIP switch

selectable as a percentage of the locked rotor torque (LRT), ranging from 15…65% of full value.

The starting time is customer set, ranging from 2…15 seconds.

• Current limit start is used when a limitation of the maximum starting current is necessary. This is

DIP switch selectable and can be adjusted from 150…450% of full load amps. The current limit

starting time is customer set, ranging from 2…15 seconds.

• Other operation modes of this device are kick start and soft stop, but these must be disabled for

the control of the air conditioner.

Additional features:

• Motor overload: The overload is DIP switch selectable. The overload trip class is selectable for

OFF or a 10, 15, or 20 protection. A current transformer (CT) monitors each phase. The motor’s

full load current rating is set by a potentiometer. The overload reset option can be operated either

manually or automatically.

• Fault indication: this device monitors both the pre-start and running modes. A single LED is used

Loading...

Loading...