Section 6

MAINTENANCE

22

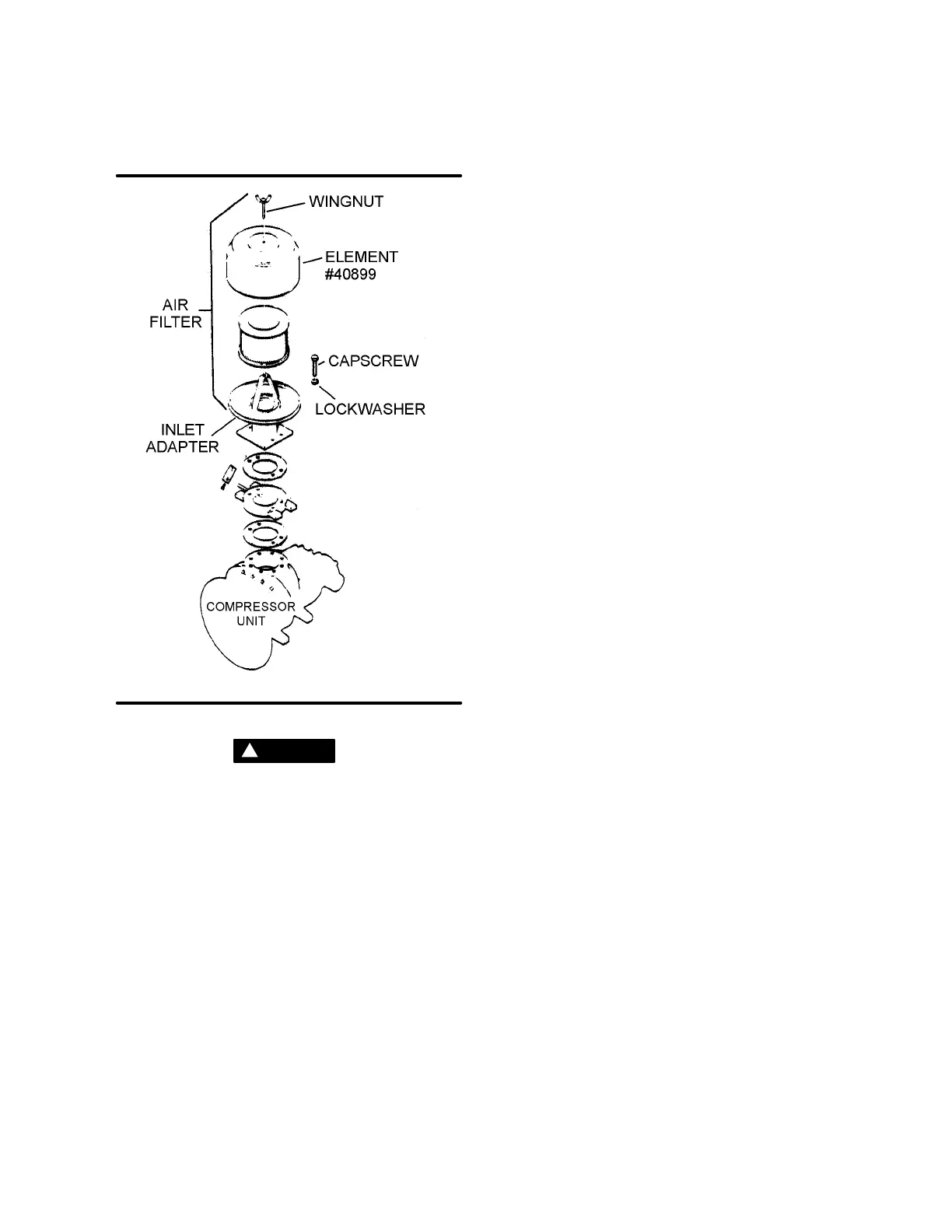

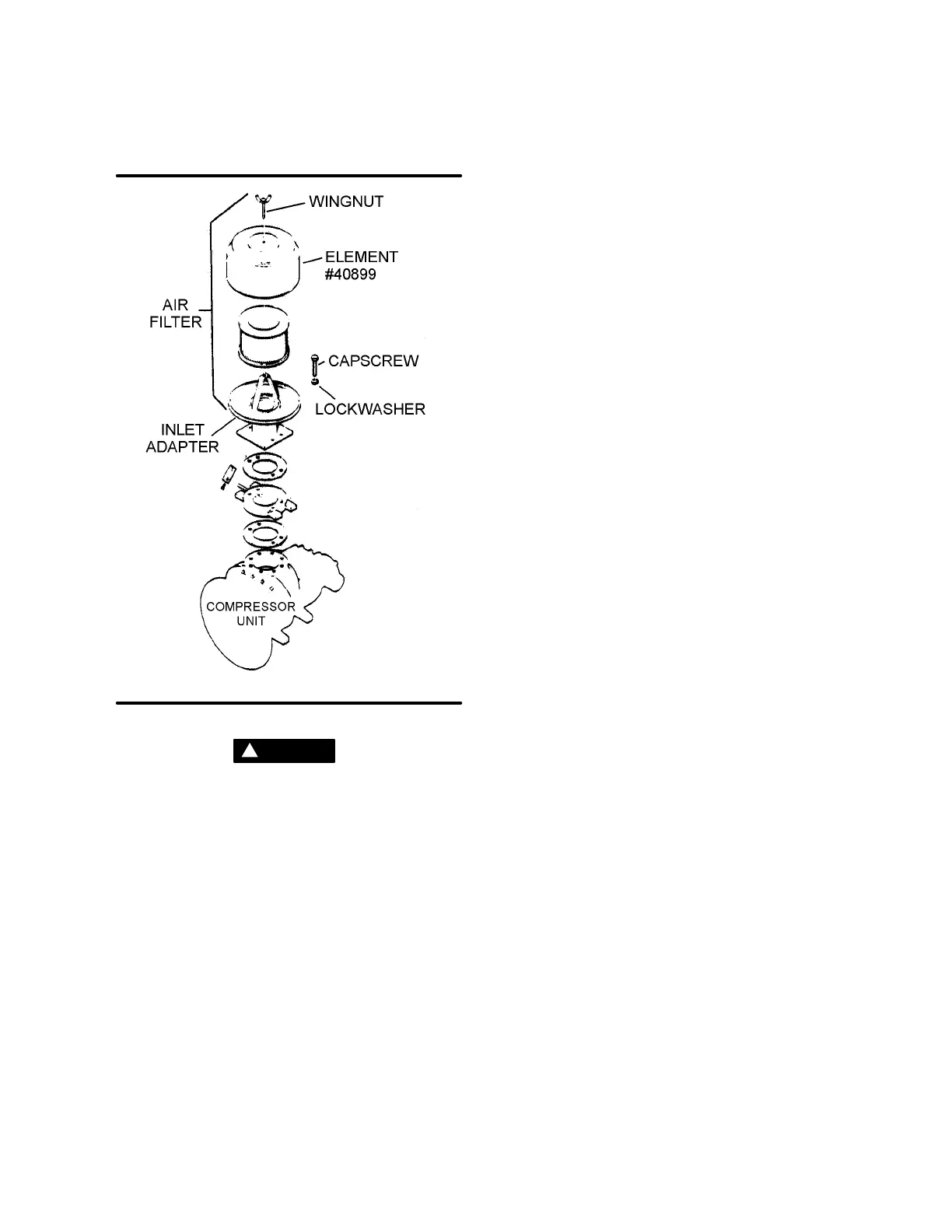

Figure 6-2 Air Filter Replacement

* Replacement Element Kit P/N 040899

(P/N 250020-315)

CAUTION

!

To minimize the possibility of filter e le ment rup-

ture, it is important that ONLY replacement ele-

ments identified with the Sullair name , logo and

appropriate part number be used and that substi-

tuted ele ments not be used, due to the fact that

such filters may have inadequate or questionable

working pressure ratings.

AIR FILTER MAINTENANCE

Refer to Figure 6-2. Air filter maintenance should be

performed when the maintenance gauge shows red

or once a year, whichever comes first. The air filter

(P/N 250030-092) supplied with your compressor

has a cleanable-type element. If the filter needs to be

replaced, order element No. 040899. Below you will

find procedures on how to replace and how to clean

the air filter element.

AIR FILTER ELEMENT REPLACEMENT

1. Clean exterior of air filter housing.

2. Remove the air filter cover by loosening the wing-

nut securing the cover.

3. Remove element and clean interior of housing us-

ing a damp cloth. DO NOT blow dirt out with com-

pressed air.

4. At this time clean or replace the element.

5. Reassemble in the reverse order of the disassem-

bly.

AIR FILTER ELEMENT CLEANING

The air filter element is cleanable by using com-

pressed air. The maximum amount of times that an

element should be cleaned is six (6) times however,

the element should be used no longer than a period

of one (1) year without changing.

Also, prior to cleaningan element, check theelement

for damage. Damaged elements must be replaced.

Compressed air shall be used for cleaning except in

full compliance with OSHA Std. 29 CFR

1910.242(b).

DO NOT strike the element against any hard surface

to dislodge dust. This will damage the sealing sur-

faces and possibly rupture the element.

DO NOT blow dirt out of the interior of the filter hous-

ing. This may introduce dust downstream of thefilter.

Instead, use a clean damp cloth.

DO NOT oil the element.

CLEANING THE ELEMENT WITH COM-

PRESSED AIR

When cleaning the element with compressed air,

never let the air pressure exceed 30 PSIG (207kPa).

Reverse flush the element by directing the com-

pressed air up and down the pleats in the filter media

from the “clean side” of the element. Continue re-

verse flushing until all dust is removed. Should any

fluid or greasy dirt remain on the filter surface, the

element should then be replaced. When the element

is sufficiently cleaned, inspect thoroughly prior to in-

stallation (see Element Inspection).

ELEMENT INSPECTION

1. Place a bright light inside the element to inspect for

damage or leak holes. Concentrated light will

shine through the element and discloseanyholes.

2. Inspect all gaskets and gasket contact surfaces of

the housing. Should faulty gaskets be evident,

correct the condition immediately.

3. If the clean element is to be stored for later use, it

must be stored in a clean container.

4. After the element has been installed, inspect and

tighten all air inlet connections prior to resuming

operation.

SEPARATOR ELEMENT REPLACEMENT

Refer to Figure 6-3. The separator elements must be

changed whenthemaintenance gauge shows red, or

once a year whichever occurs first. Order separator

element numbers 250034-116 (primary) and

250034-118 (secondary). Follow the procedure ex-

plained below for separator element replacement.

1. Relieve all pressure from the sump tank and all

compressor lines.

2. Disconnect all pipingconnected to the sump cover

to allow removal (return lines, service lines, etc.).

Loading...

Loading...