SECTION 3 4500P-7500 USER MANUAL

25

3.4 LUBRICATION GUIDE

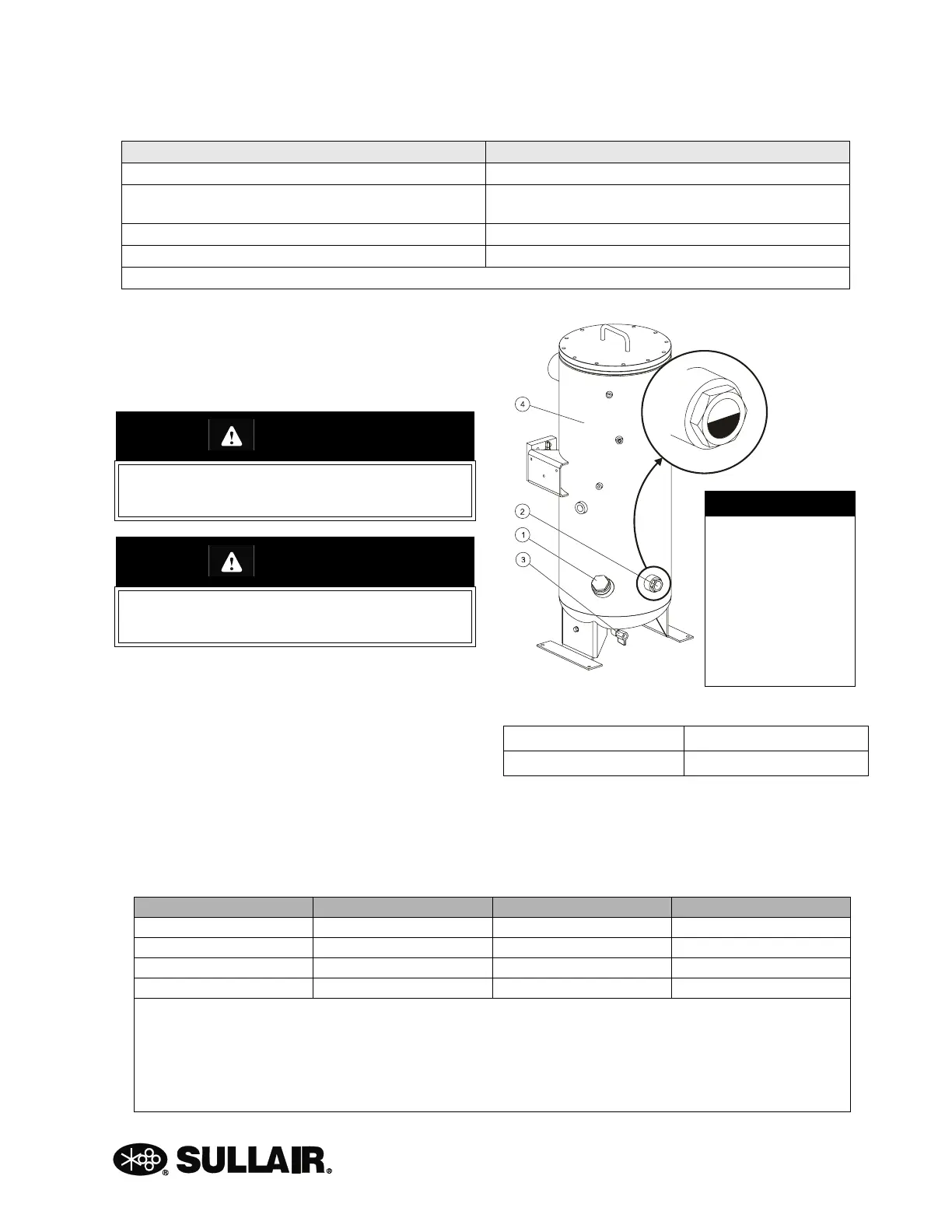

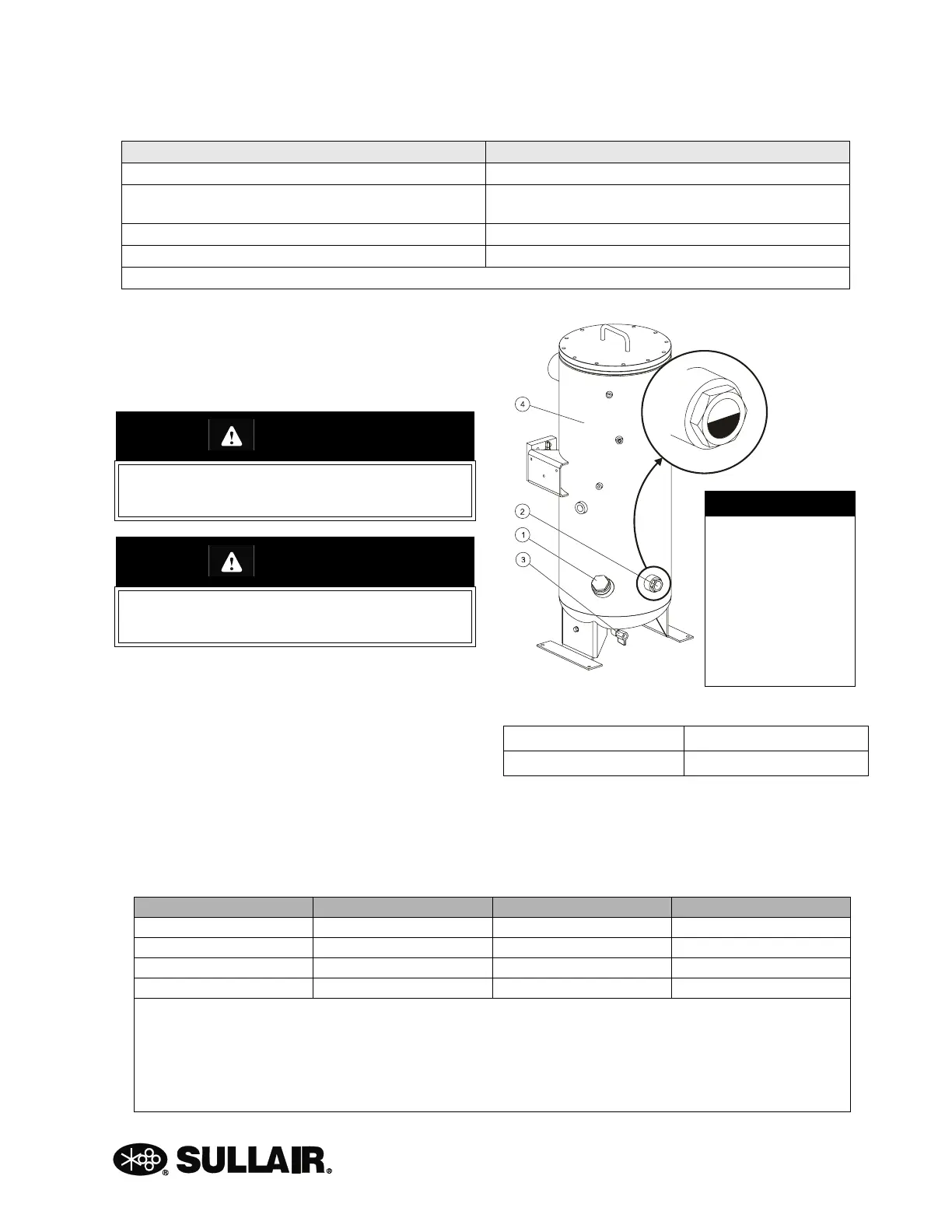

Refer to Figure 3-1 for the fluid fill port location.

Sullair’s 4500P-7500 series compressors are filled

and tested at the factory with Sullube lubricant.

3.5 APPLICATION GUIDE

Sullair encourages its customers to participate in a

fluid analysis program with the fluid suppliers. In

some cases the analysis results suggest a fluid

change interval which differs from the User Manual.

Contact a Sullair representative for details.

Figure 3-1: Fluid Fill Location

CAUTION

Do not mix different types of lubricants. Mixing

lubricants can cause malfunctions or compressor

damage: will void the compressor’s warranty.

CAUTION

Contamination of compressor fluids with mineral

oil or other fluids can cause foaming, filter

plugging, or orifice line obstruction.

1. Fluid Fill Port 3. Fluid Drain Valve

2. Sight Glass 4. Receiver Tank

3.3 COMPRESSOR SPECIFICATIONS

COMPRESSOR: STANDARD MODELS:

Type: Rotary Screw

Standard Operating Pressure:

100 psig (7 bar) 125 psig (9 bar) / 150 psig (10.0 bar)

175 psig (12.0 bar)

Bearing Type: Anti-friction

Ambient Temperature (Max.) (II): 104ºF (40ºC)

(II) Special compressors are available for operating in higher ambient temperature.

3.6 LUBRICATION CHANGE RECOMMENDATIONS AND

MAINTENANCE, FLUID FILTER AND SEPARATOR

LUBRICANT FLUID CHANGE FLUID FILTER CHANGE SEPARATOR CHANGE

Sullube A,E G,C A,D

SRF 1/4000 B, E G, C B, D

24kt F, E G, C A, D

CP-4600-32-F B, E G, C A, D

A - 8,000 hours or once per year.

B - 4,000 hours or more frequntly if conditions require.

C - When measured pressure loss exceeds 20 psig (1.3 bar).

D - When measured pressure loss exceeeds 10 psig (0.7 bar).

E - When required as the result of fluid analysis or known contamination.

F - Does not require replacement under normal service conditions.

G - Every 2,000 hours.

NOTE

When performing a fluid

change or topping off the

fill, the proper level

should be at half of the

sight glass, with the

machine off.

Mixing, changing or add-

ing other lubricants within

the compressor unit may

void the air-end warranty.

Loading...

Loading...