Section 2

DESCRIPTION

6

warranty.

Fluid is injected into the compressor unit at each

stage, and mixes directly with the air as the rotors

turn, compressing the air. The fluid flow has three

main functions:

• As coolant, it controls the rise of air temper-

ature normally associated with the heat of

compression.

• Seals between the rotors and the stator and

also between the rotors themselves.

• Acts as a lubricating film between the rotors

allowing one rotor to directly drive the other,

which is an idler.

After the air/fluid mixture is discharged from the

compressor unit, the fluid is separated from the air.

At this time, the air flows to the service line and the

fluid is cooled in preparation for reinjection.

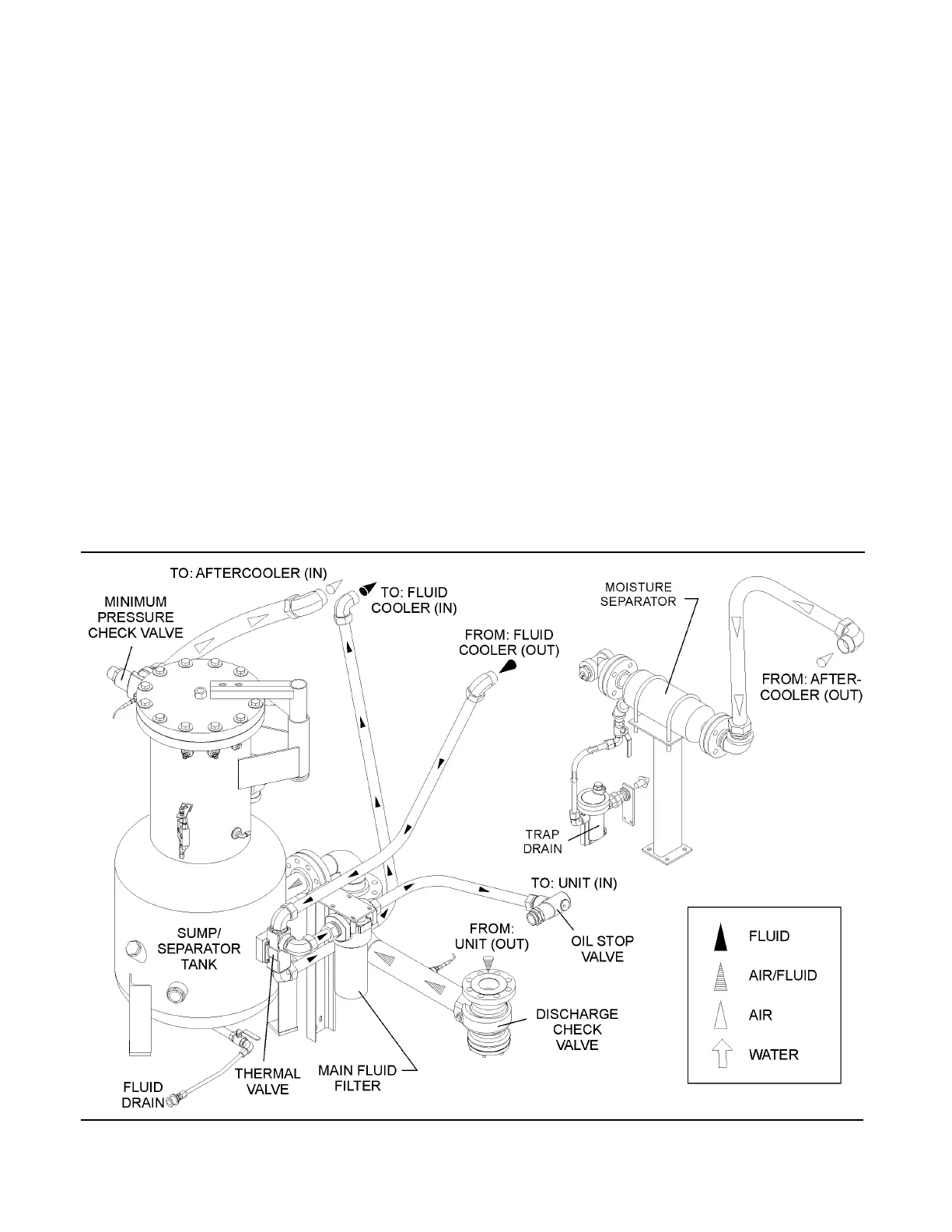

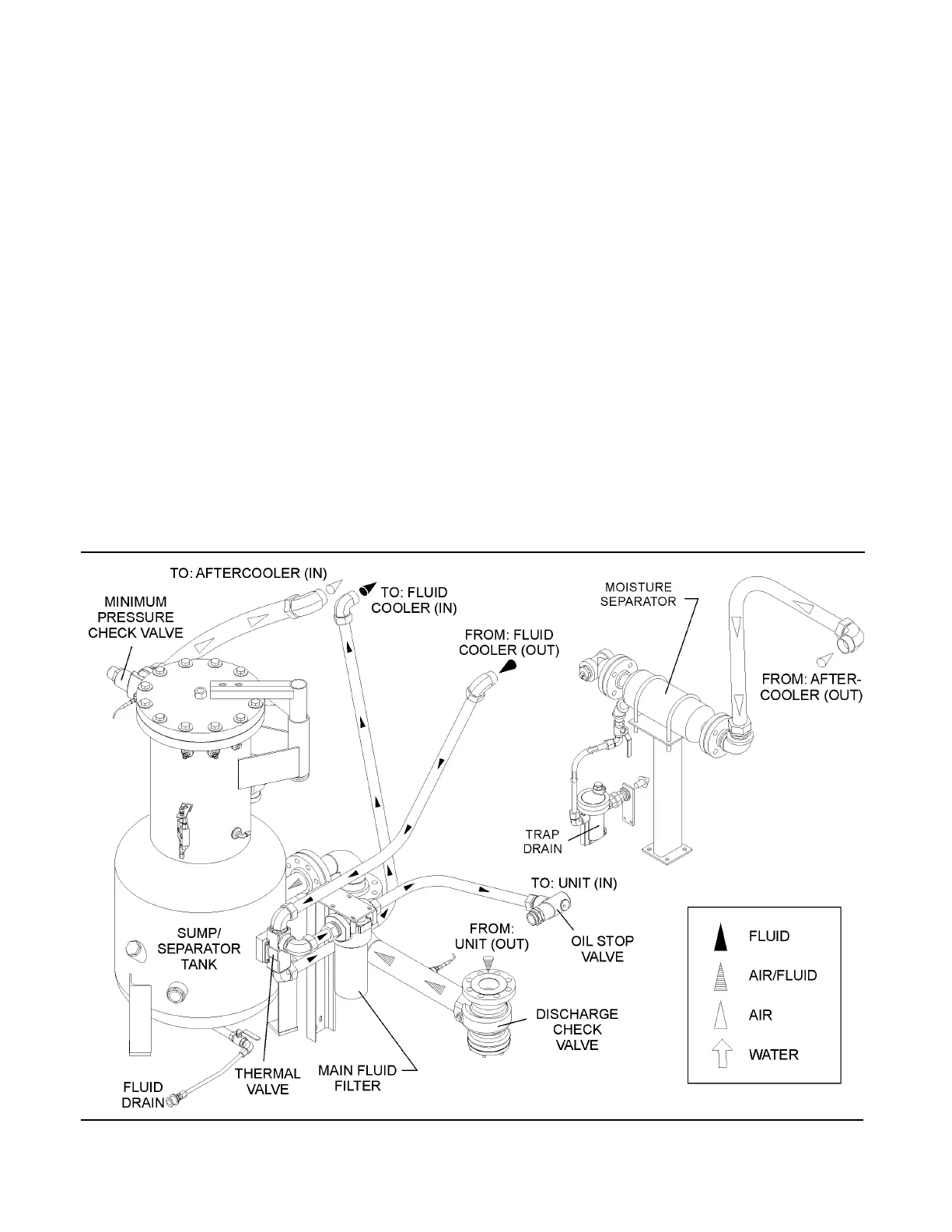

2.4 COMPRESSOR COOLING AND LUBRICATION

SYSTEM, FUNCTIONAL DESCRIPTION

Refer to Figures 2-2, 2-3A and 2-3B. The cooling

and lubrication system consists of a fluid cooler,

aftercooler, full flow fluid filters, fluid stop valve,

thermal valve and interconnection piping. For

water-cooled models, a shell and tube fluid cooler

and aftercooler are mounted on the compressor

package. For air-cooled models, they are radiator-

type coolers, and are mounted on the compressor

package.

The pressure in the receiver/sump causes fluid flow

by forcing the fluid from the high pressure area of

the sump to an area of lower pressure in the com-

pressor unit.

Fluid flows from the bottom of the receiver/sump to

the thermal valve. The thermal valve bypass is fully

open when the discharge temperature is below

220ºF (104.4ºC). The fluid passes through the ther-

mal valve, the main fluid filter and directly to the

compressor unit, thus feeding the bearings, seals

and rotor area.

As the discharge temperature rises above 220ºF

(104.4ºC), due to the heat of compression, the

Figure 2-2 Compressor Cooling, Lubrication and Discharge System

Loading...

Loading...