Section 2

DESCRIPTION

5

2.1 INTRODUCTION

Your new Sullair lubricated rotary screw air com-

pressor will provide you with a unique experience in

improved reliability and greatly reduced mainte-

nance.

Compared to other types of compressors, the

Sullair rotary screw is unique in mechanical reliabil-

ity, with minimal wear and no inspection required of

the working parts within the compressor unit.

Read Section 6 (Maintenance) to see how to keep

your air compressor in top operating condition.

Should any questions arise which cannot be

answered in the following text, call your nearest

Sullair representative or the Sullair Corporation

Service Department.

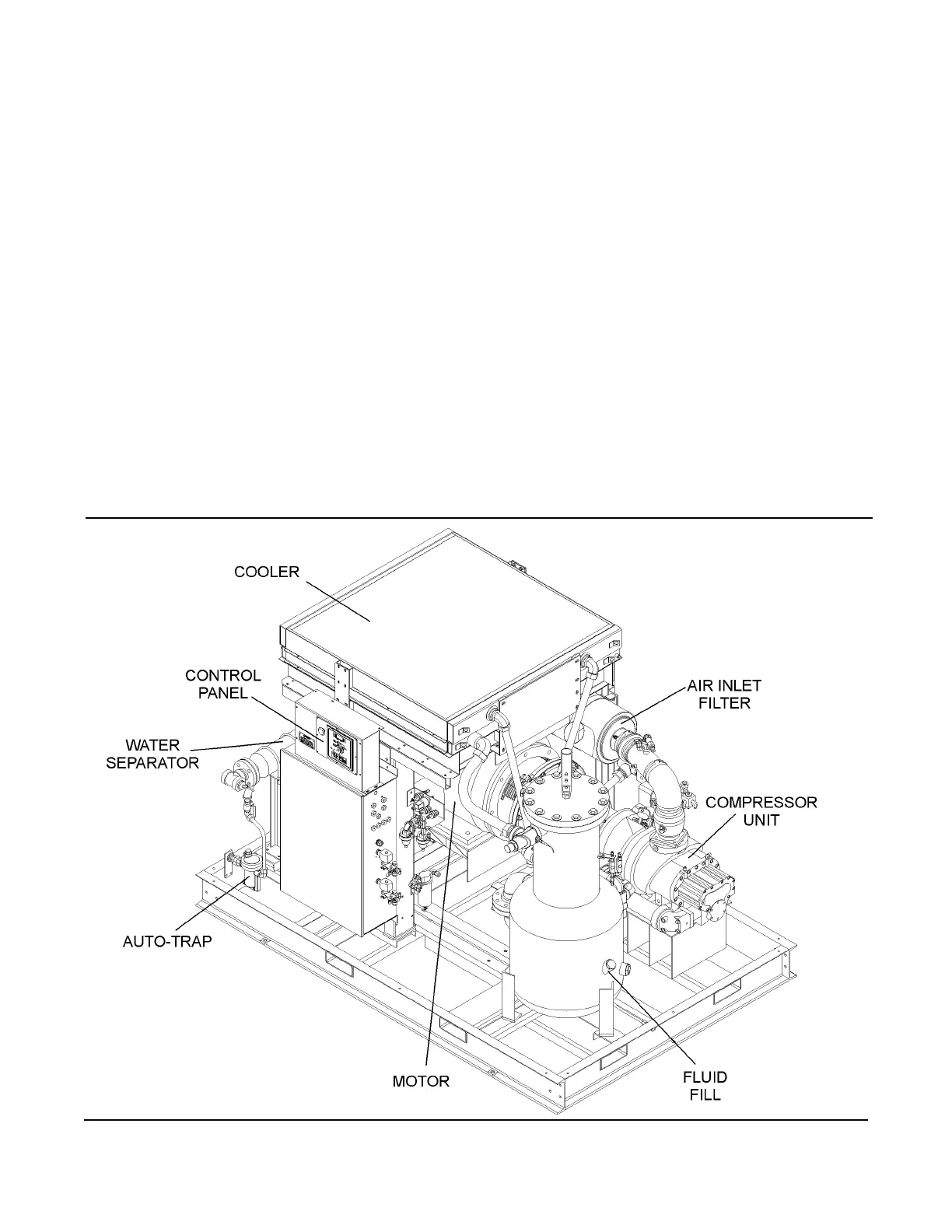

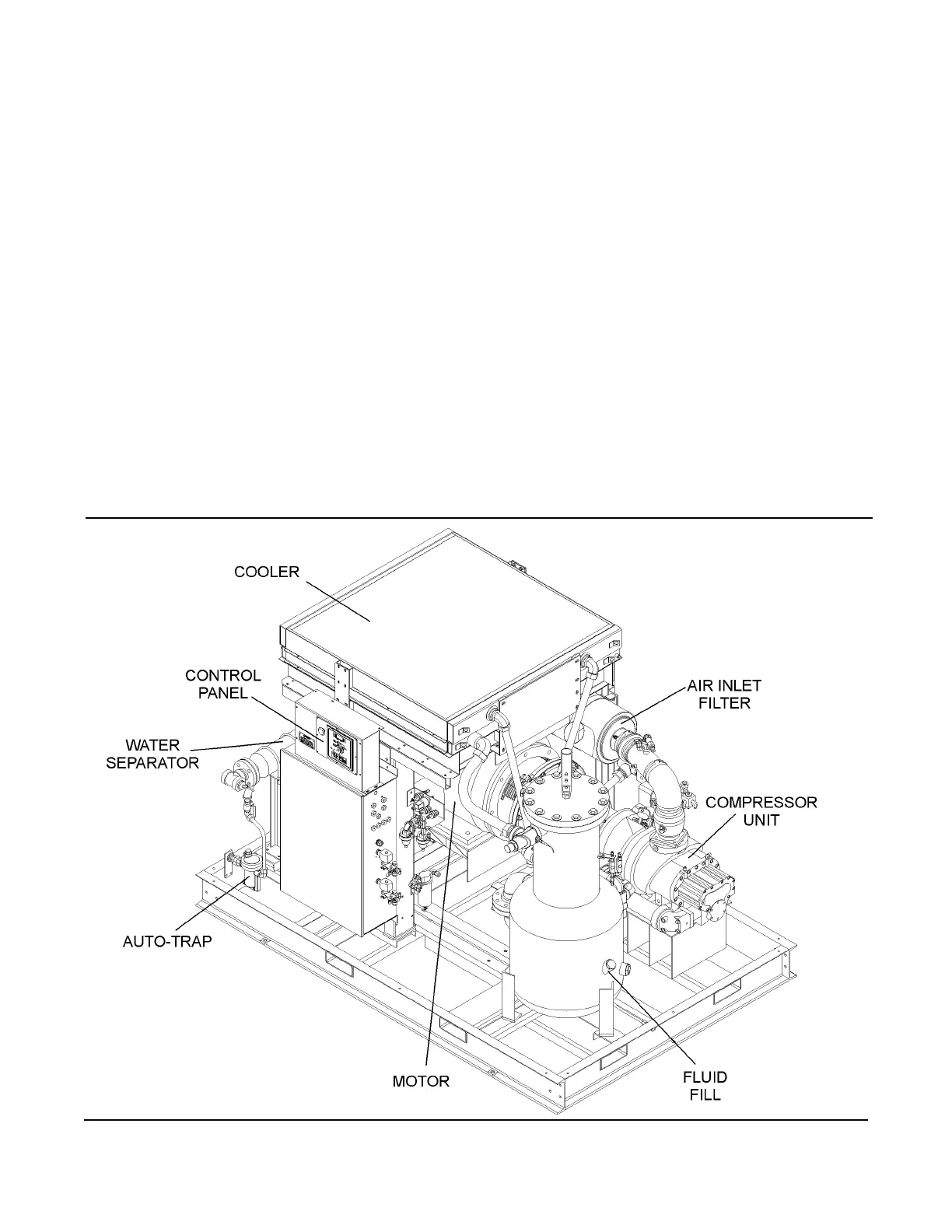

2.2 DESCRIPTION OF COMPONENTS

Refer to Figures 2-1. The components and assem-

blies of the air compressor are clearly shown. The

complete package includes compressor, electric

motor, compressor inlet system, compressor

discharge system, compressor cooling and

lubrication system, capacity control system and

“Supervisor II Control System” all mounted on a

structural steel frame.

On air-cooled models, the cooling package is

mounted within the package. The separate motor-

driven fan cooling package forces air through the

coolers, which removes the heat of compression

from the cooling fluid.

2.3 SULLAIR COMPRESSOR UNIT, FUNCTIONAL

DESCRIPTION

Sullair air compressors feature the Sullair compres-

sor unit, a two-stage, positive displacement, lubri-

cated-type compressor. This unit provides continu-

ous pulse-free air compression to meet your needs.

With a Sullair compressor, there is no maintenance

or inspection of the internal parts of the compressor

unit permitted in accordance with the terms of the

Figure 2-1 Sullair Series LS16T Rotary Screw Compressor- Air-cooled (Typical)

Loading...

Loading...