Section 6

MAINTENANCE

42

12. Check the return line strainer before restarting

the compressor (replacement strainer P/N

02250117-782).

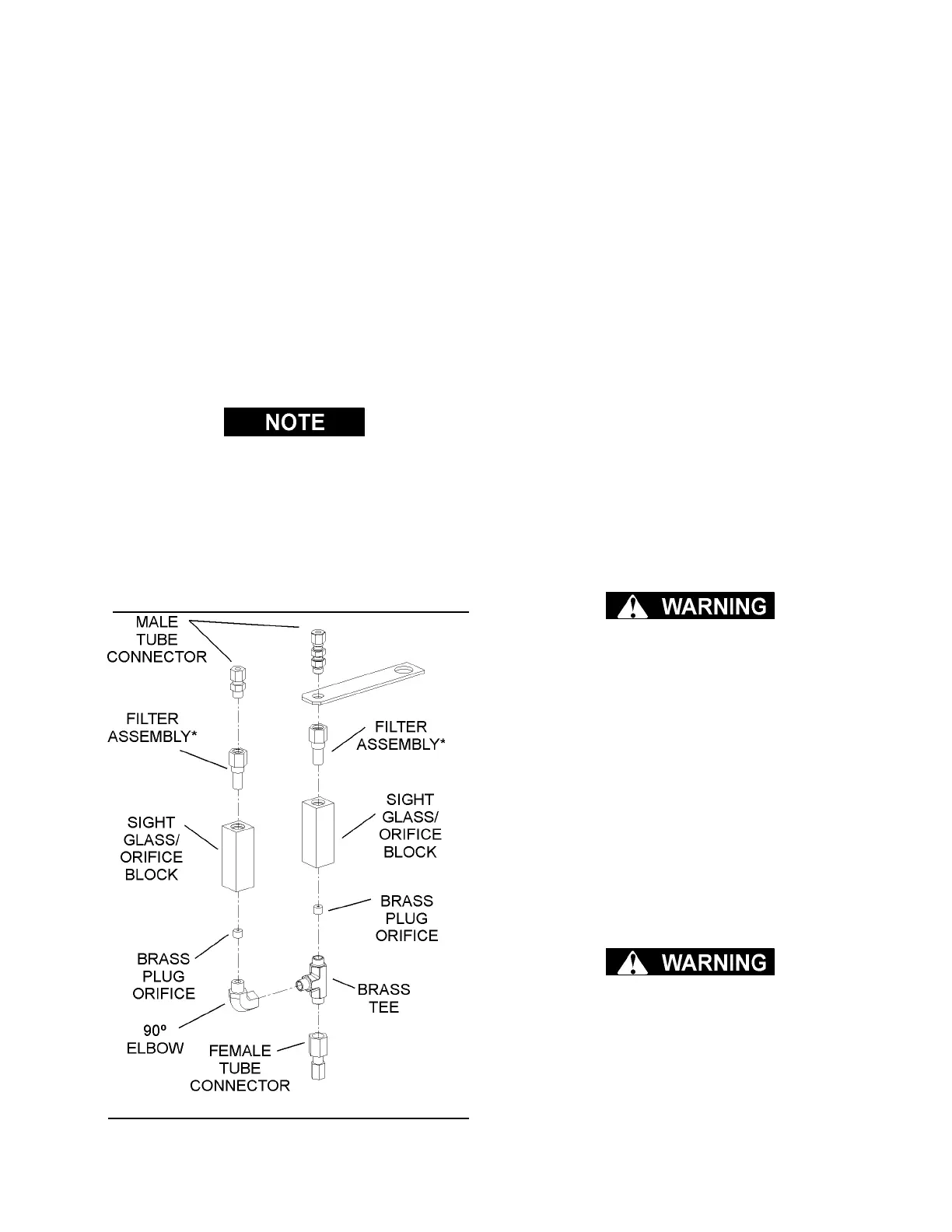

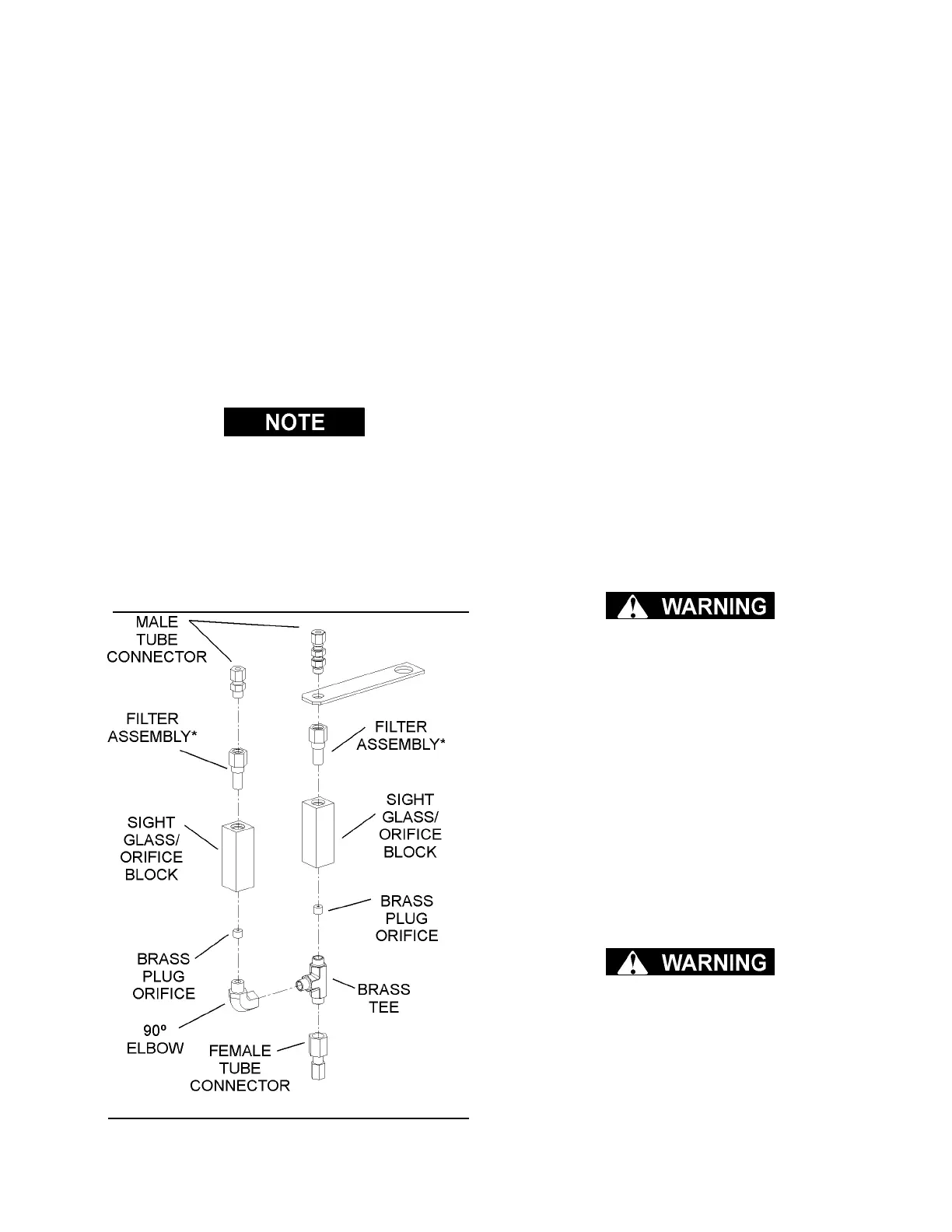

OIL RETURN/SIGHT GLASS MAINTENANCE

Refer to Figure 6-4. The oil return/sight glass sub-

assembly is attached to the separator tank lid. Oil

return/sight glass maintenance should be per-

formed on a routine basis parallel to that of the fluid

filter, or as indicated in the Troubleshooting

Sections (both Supervisor II and Maintenance) of

this manual. The maintenance on an oil

return/sight glass is mainly concerned with the con-

dition of the filter assembly. Order filter assembly

no. 02250117-782, and use the following instruc-

tions as a guide.

Always performing maintenance on both oil

return/sight glasses at the same time.

1. Disconnect the tubes at the tops of the sight

glass assemblies.

2. Unscrew male connector (for left-side glass), or

the straight thread tube connector (for right-side

glass) from sight glass/orifice blocks.

3. Remove used filter assembly, and replace with

new assembly.

4. Coat/lubricate the o-rings will silicone grease.

5. Reattach the connectors to the sight glass/orifice

blocks.

DIFFERENTIAL PRESSURE REGULATOR

ADJUSTMENT

Refer to Figure 6-5 and 6-6. The differential pres-

sure regulators are adjusted by loosening the

adjusting screw on the end of the cone-shaped

cover of the pressure regulator. When the jam nut

is loose, turn the adjusting screw clockwise to

increase or counterclockwise to decrease the set-

ting.

The reference pressure regulator should be set to

maintain a 60 psig (4.14 bar) downstream pressure

to the inlet poppet valve. The unload pressure reg-

ulator should be set at 175 psig (12.1 bar) to con-

trol the compressor package during unload only.

The inlet poppet valve control pressure regulator

should be set to control the systems modulation to

the service line desired pressure.

DRIVE COUPLING INSTALLATION AND ALIGN-

MENT

Applies to base-mounted compressors and drives

only. Units mounted through common housing

are self-aligning. If alignment is suspect, use the

following procedure.

Refer to Figures 6-6, 6-7 and 6-8. For coupling

installation and alignment, the tools required will be

one set of standard allen wrenches and a dial indi-

cator. If a dial indicator is not available, an alternate

method of checking the alignment may be used as

a secondary or less desirable technique. This

method of checking is done by careful use of a

square or metal straight edge feeler gauge and a

set of inside calipers (see Figure 6-8). Those spec-

ifications in Table 6-1 Installation Data which are

designated in inches are provided for this method.

For installation and maintenance of the drive cou-

pling, follow the steps explained below.

Disconnect all power at source, before attempting

maintenance or adjustments.

STEP 1 - MOUNT HUBS

After, carefully inspecting the hub bores and the

shafts for dirt and burrs, mount the motor hub and

the compressor hub on their respective shafts. It is

also necessary to check for a proper key fit. Place

Figure 6-4 Oil Return/Sight Glass

*Replacement Filter Assembly P/N 02250117-782

Loading...

Loading...