14

Beier frame size

Horizontal type

A type B type

N10A N8B

15A 10B

20A 15B

30A

40A

20B

30B

Trochoid pump Pump motor

Vertical type

Trochoid pump Pump motor

– – TOP-13AK 0.2kW 4P

– – TOP-208HB 0.4kW 4P

– – TOP-212HB 0.4kW 4P

– – TOP-216HB 0.75kW 4P

50A

75A

100A

150A

200A

50B

75B

100B

150B

TOP-212HB

TOP-N350HVB-7

With relief valve

0.75kW 4P TOP-N330H

TOP-N350HVB-7

With relief valve

2.2kW 6P

2.2kW 6P

Table 6 Trochoid Pump Specification for Beier portion

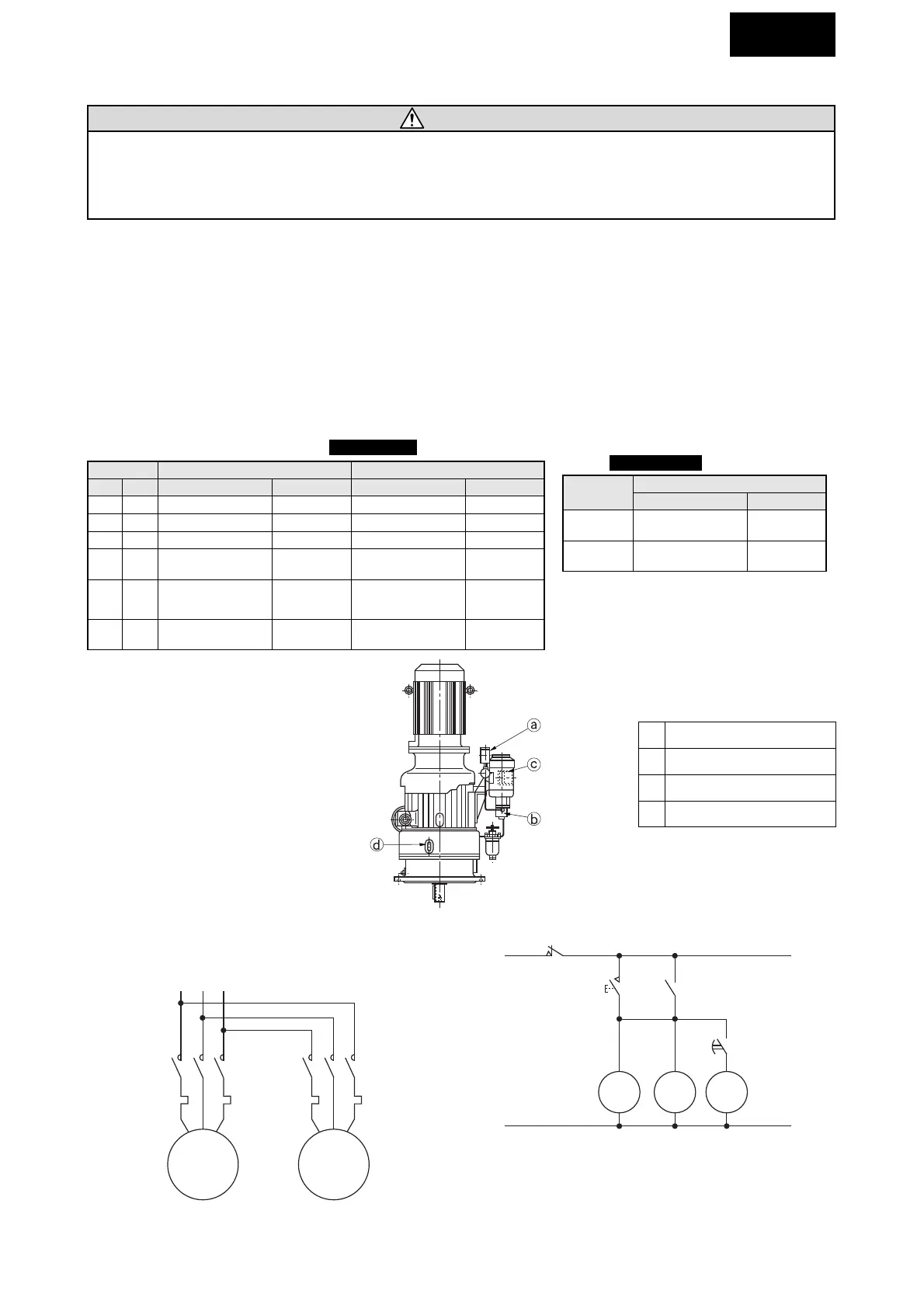

a

b

c

d

Pressure gauge

Trochoid pump

Motor (For Trochoid pump)

Oil level gauge

Fig. 10 Trochoid Pump Construction

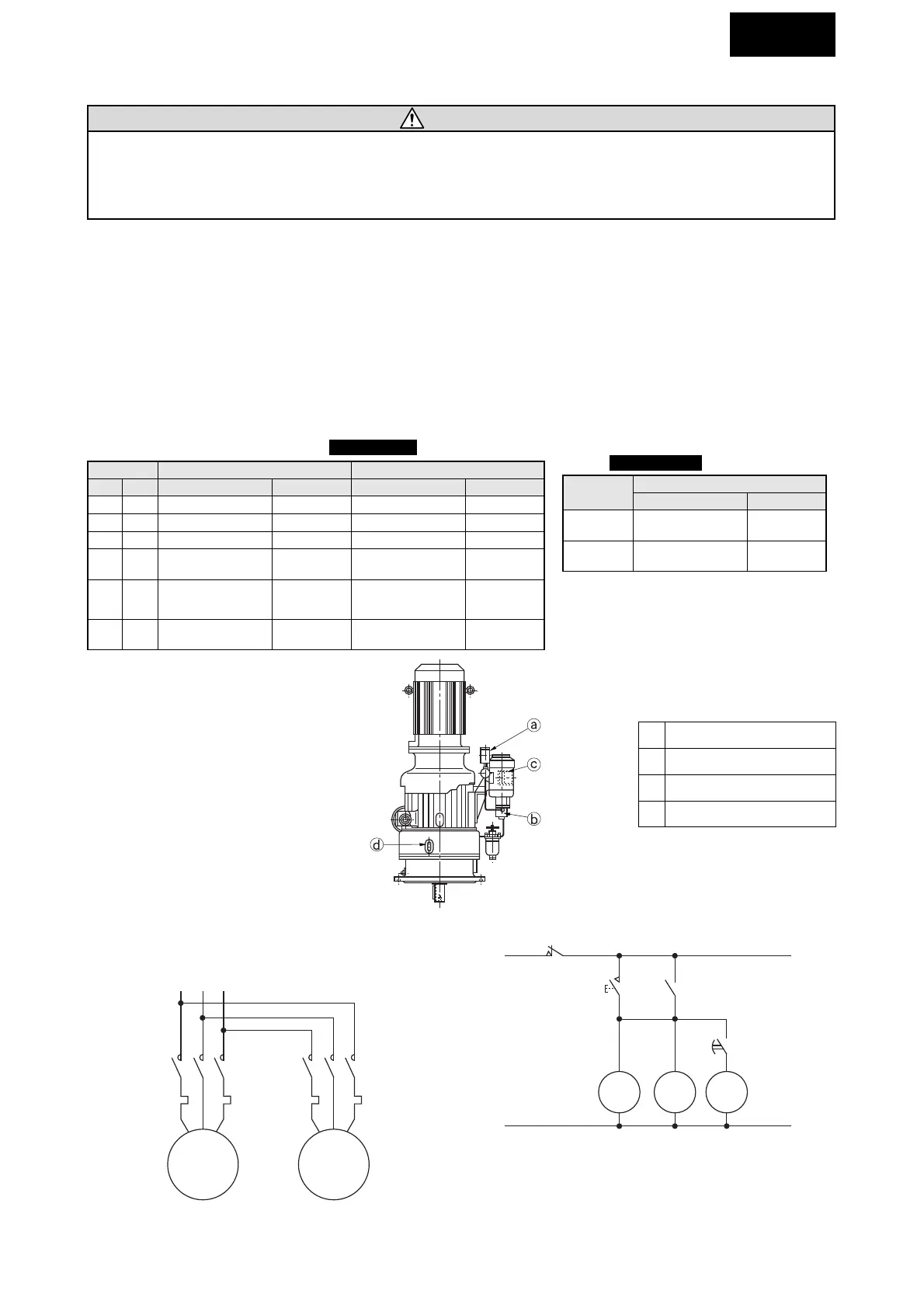

Fig. 11 Torochoid Pump Wiring Diagram

MC1 : Electromagnetic switch (For Main motor)

MC2 : Electromagnetic switch (For Trochoid pump motor

PB1 : Push button switch (For Starting)

PB2 : Push button switch (For Stopping)

T : Timer (Approx, 30 sec. or more)

Cyclo frame

size

6275

Vertical type

Trochoid pump

TOP-216HBVB-3

With relief valve

Pump motor

0.75kW 4P

6275DA

TOP-204HBVB-3

With relief valve

0.4kW 4P

Table 7 Trochoid Pump Specification for

Cyclo portion

Lubrication oil cooling device will be

set separately for over 50A and 50B.

Refer to "9. Lubricating Oil Cooling

Device (page 28)."

COMMON

CAUTION

Conduct priming shown in the maintenance manual, before the start up of the main motor, in case of forced oil

lubrication by the trochoid pump; otherwise damage to the equipment may result.

For forced oil lubrication by trochoid pump, prime the pump, as shown in the maintenance manual, before starting

the main motor; otherwise, the equipment may be damaged.

(1) Because forced lubrication by the trochoid pump is necessary for the models with trochoid pump system as in "8-2

Confirmation of Lubrication Method (page 17)", a separate power source should be prepared for the pump. (Refer to

Table 6, 7 and Fig.10)

(2) Refer to Fig.11 for the trochoid pump wiring. At this point, connect so that the pump motor will rotate the designated

direction.

(3) Establish an electrical interlocking device between the trochoid pump motor and main motor that satisfies the following

two functions; (Refer to Fig.11)

1 Start-up time-The main motor stops when the trochoid pump stops.

2 During operation-The main motor stops when the trochoid pump stops for some unknown reason.

(4) To assure optimal lubrication conditions, the trochoid pump should be started-up at least 30 seconds before the start-up

of the main motor. (priming)

6-6) Trochoid Pump Connection

Loading...

Loading...