8

FB BRAKE ASSEMBLY – INSPECTION,

ADJUSTMENT & MAINTENANCE

SM-Cyclo FB series brakemotors are designed to be

mechanically rugged, electrically reliable and efficient

in operation. To maintain this reliable performance,

the brake assembly must be inspected and adjusted

periodically.

Brake Models FB-01A, FB-02A and FB-05A

1. Standard Brakemotor Specifications

Table 8 lists the standard specifications for Models

FB-01A, FB-02A and FB-05A.

This section of the manual pertains specifically to the

brake portion of the SM-Hyponic gearmotor and

provides all the necessary information to insure long

and trouble-free service.

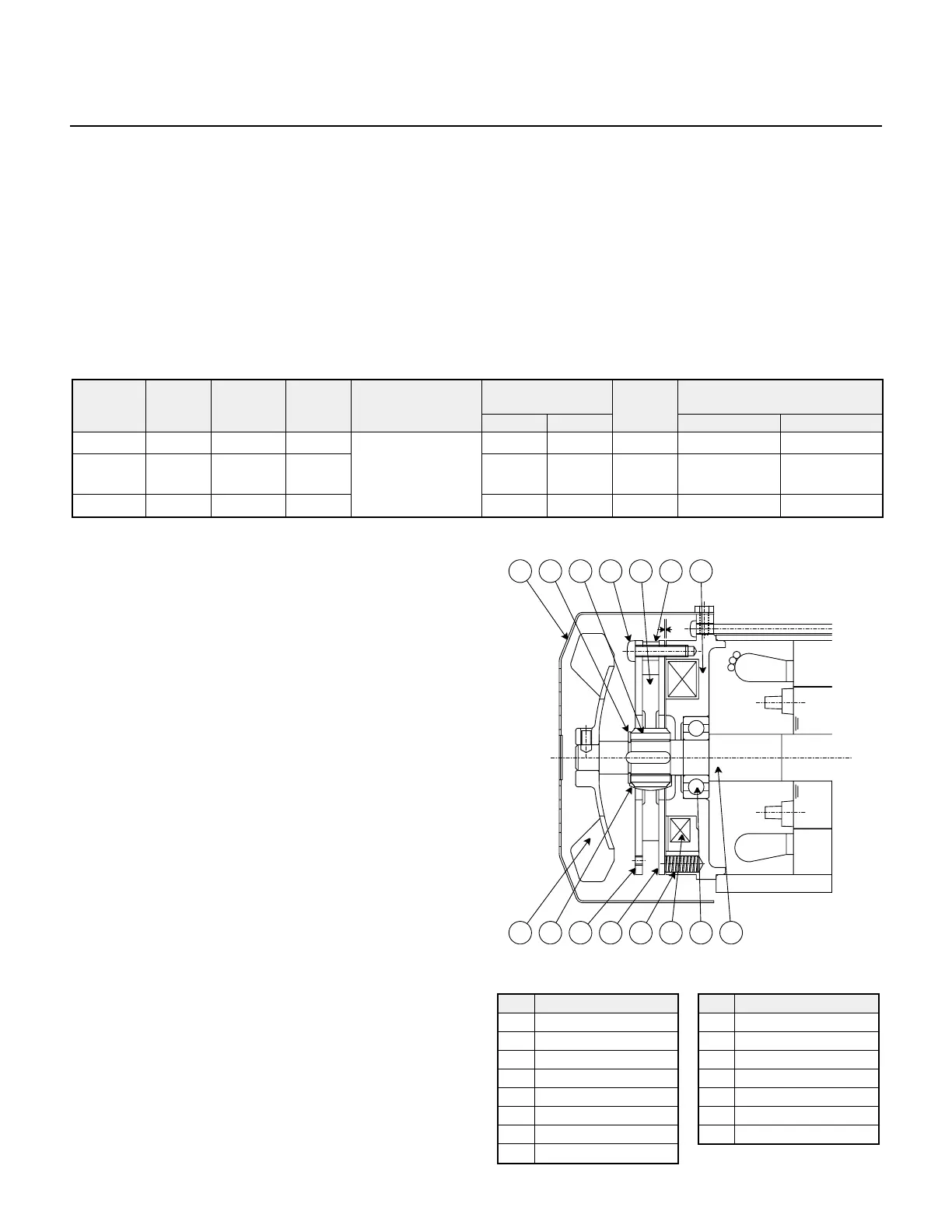

Table 8 Models FB-01A, FB-02A, FB-05A Standard Specifications

Brake Motor

Brake Inertia

Brake

Brake Current

Coil

Brake Delay Time

Type HP

Torque WK

2

Coil

(A)

Resis

(seconds)

ft-lb lb-ft

2

230V 460V

ohms

Normal Fast

FB-01A 1/8 0.7 0.0083

DC Energized

0.1 0.06 2700 0.15 ~ 0.2 0.015 ~ 0.02

FB-02A

1/4

1.4 0.0131

Type, Built-in

0.1 0.06 1791 0.15 ~ 0.2 0.015 ~ 0.02

1/3

Rectifier within

FB-05A 1/2 2.9 0.016

Conduit Box

0.1 0.06 1791 0.1 ~ 0.15 0.01 ~ 0.015

Notes:1) Continuous time rating for both the brake and motor.

2) Indoor types can be installed for use in any orientation.

2. Construction and Operating Principles

a. Construction

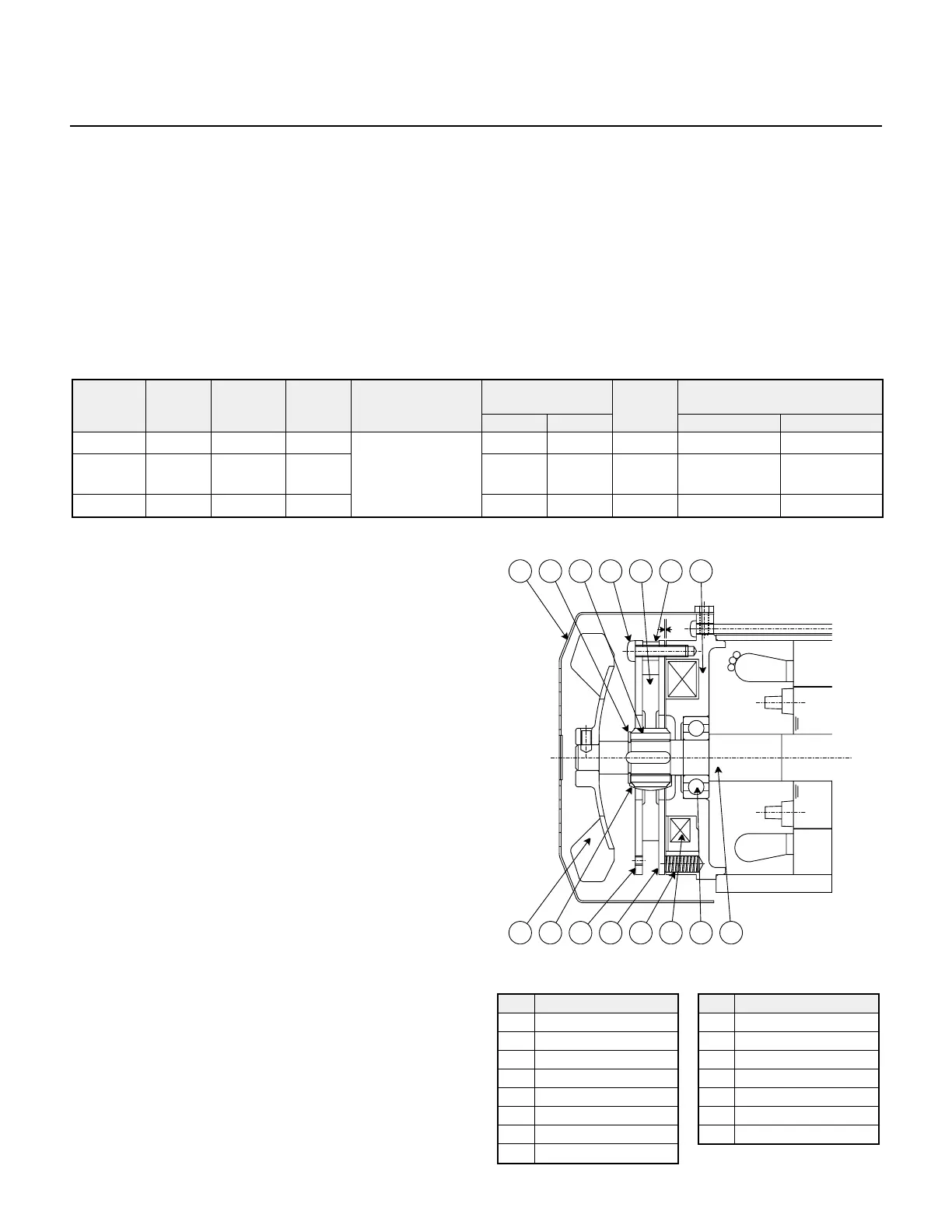

Fig. 17 illustrates the construction of the brake.

The restraining bolt (4) fastens the brake shoe (10)

and spacer (2) onto the stationary core (1). The

armature plate (11) is kept from rotation by the

restraining bolt (4) but moves axially by

electromagnetic attraction and the tension of the

pressure spring (12). The brake lining (3) is fitted

to the hub (5), which is secured to the motor shaft

with a key. The solenoid coil (13) is energized via

a rectifier located within the conduit box.

b. Operating Principles

The brake is a (fail-safe type) spring actuated type

brake that releases the brake mechanism when the

solenoid coil is energized and engages when the

solenoid coil is not energized.

When power is applied to the unit, the solenoid coil

and electric motor become energized and the

energized coil attracts the armature plate (11)

against the tension of the pressure spring (12). As

a result, the brake lining (3) disengages and the

motor starts to run.

When the power is disconnected, the solenoid coil

and electric motor are not energized. This causes

the pressure spring (12) to actuate the armature

plate (11), which in turn presses the brake lining (3)

against the brakeshoe (10) and brings the motor to

a quick stop.

No. Part Name

1 Stationary Core*

2 Spacer*

3 Brake Lining*

4 Restraining Bolt*

5 Hub*

6 C-type Retaining Ring

7 Cover

8 Fan (TEFC model only)

No. Part Name

9 Leaf Spring*

10 Brake Shoe*

11 Armature*

12 Pressure Spring*

13 Solenoid Coil*

14 Ball Bearing

15 Motor Shaft

*These parts are included in a complete brake kit.

Loading...

Loading...