1

MOUNTING

Solid Shaft Type

1. Mounting conditions

Ambient temperature: 14°F ~ 104°F

Humidity: 85% or less

Altitude: Lower than 3300 ft (1000 m)

above sea level

Atmosphere: Free from corrosive gases,

explosive gases or steam. It

should also be free from dust

and well ventilated.

Location: Indoors

2. Mount the gearmotor on a rigid surface.

3. There is no restriction for mounting angle.

4. Use hexagon socket head bolts when mounting

RNFM series (flange-mount type). See Table 1 for

bolt sizes.

Table 1

Series Frame Size Size of hexagon socket head bolt

20˝, 23˝ M8

30˝, 33˝ M10

RNFM

40˝, 43˝ M10

50˝, 53˝, 54˝ M12

Hollow Shaft Type

1. Mounting conditions

Ambient temperature: 14°F ~ 104°F

Humidity: 85% or less

Altitude: Less than 3300 ft (1000 m)

above sea level

Atmosphere: Free from corrosive gases,

explosive gases, steam and

dust. It should also be well

ventilated.

Location: Indoors

2. Mount the gearmotor on a driven shaft that has

sufficient rigidity.

3. There is no restriction for the mounting angle.

4. Mounting Procedures

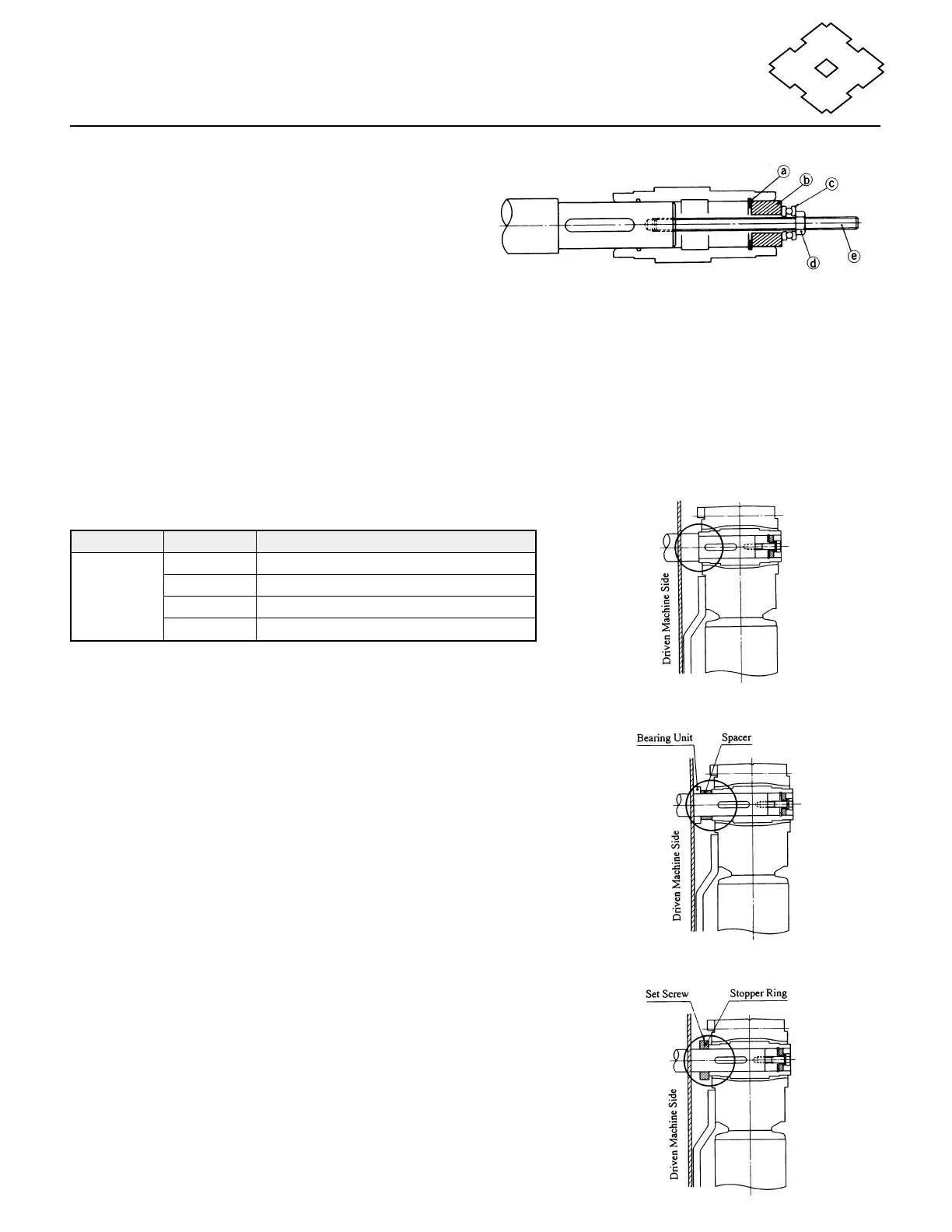

a. Connecting a Driven Shaft

Apply molybdenum disulfide grease to the surface

of the shaft and the inner surface of the hollow

shaft. Slide the SM-Hyponic onto the shaft. To

make the installation smoother if the fit is too tight,

lightly tap the end of the hollow output shaft with a

wooden hammer. Avoid hitting the casing. To

ensure smooth installation of the drive, we

recommend the use of a jig shown in Fig. 1.

The hollow shaft is made according to ISO H8

tolerances. Following installation, ensure that the

fitting between the hollow and the driven shaft is

tightened correctly. We recommend ISO js6 or k6

as the tolerance for the driven shaft.

b. Mounting the SM-Hyponic gearmotor

Fig. 1

a – Retaining ring d – Nut

b – Spacer e – Double-ended threaded bolt

c – Thrust bearing

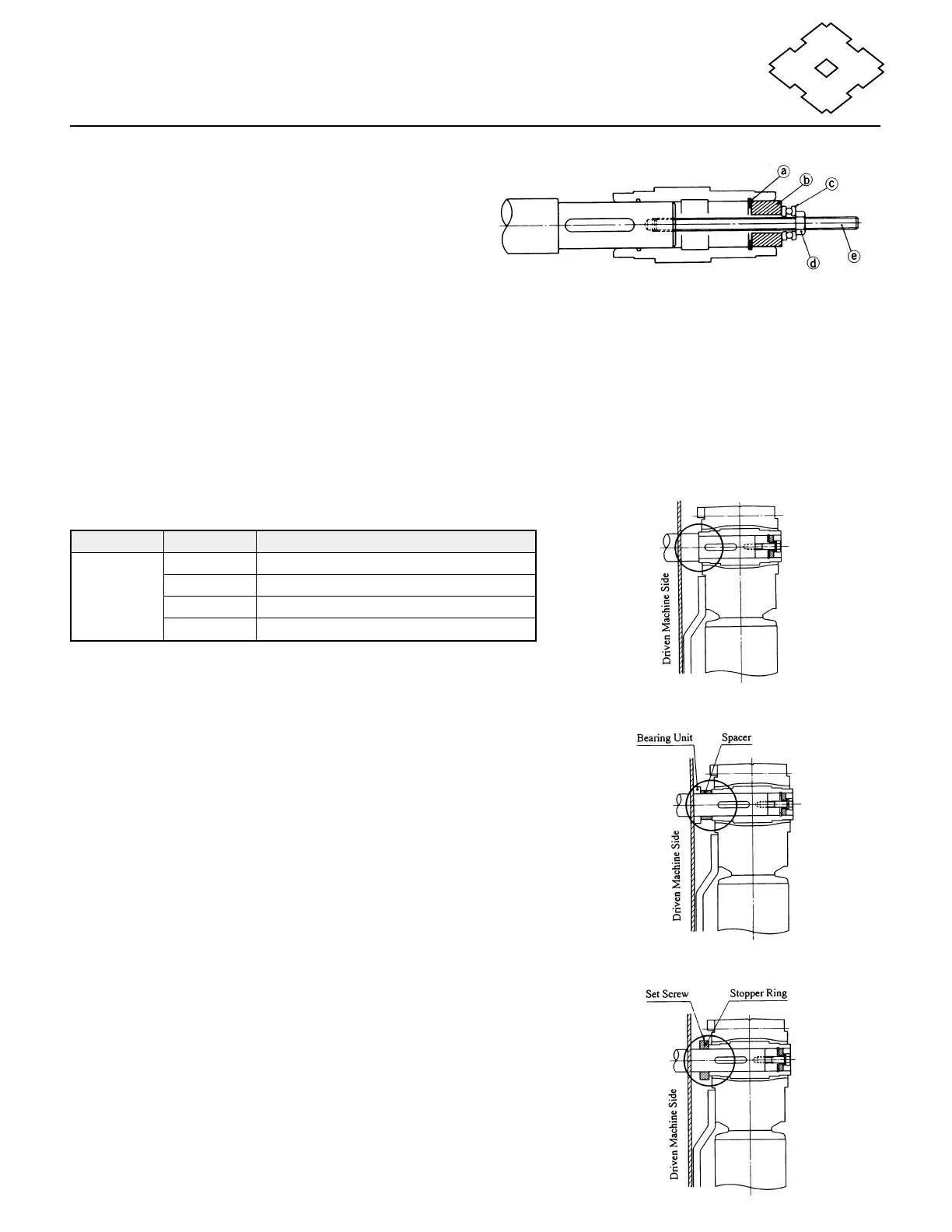

Fig. 2 Stepped Shaft Option

Fig. 3 Spacer Option

Fig. 4 Set Screw Option

Loading...

Loading...