3

MOUNTING

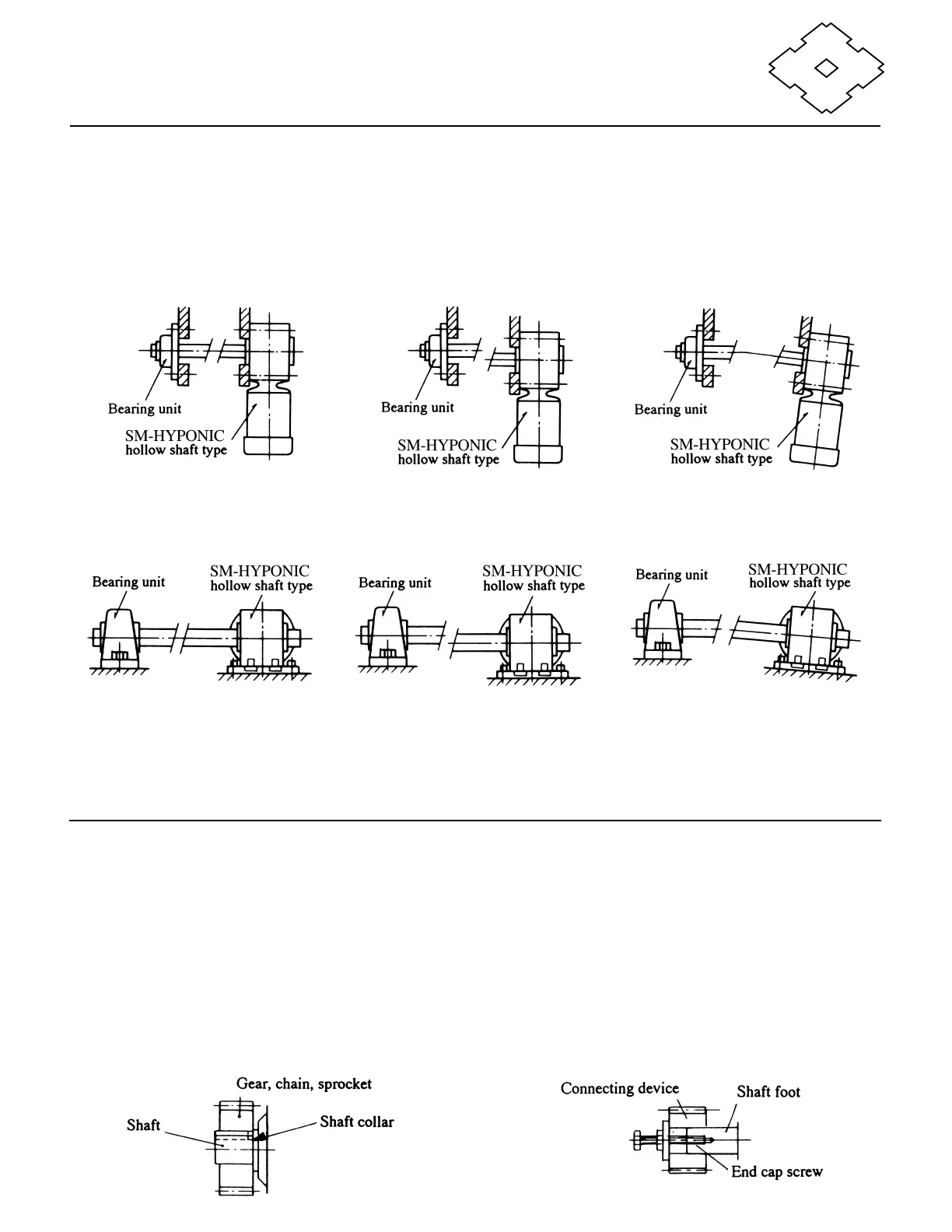

(5) Flange and Foot Mounting (optional).

When installing the SM-Hyponic, ensure that the

gearmotor and the shaft of the driven machine are

properly aligned so that the drive is free from

excessive force.

Good example Bad example Bad example

Fig. 10 Flange coupling

(The concentricity between the

shaft and mounting pilot is out of

allowable range.)

(The shaft centerline is not

positioned at right angles to the

flange.)

Good example Bad example Bad example

Fig. 11 Foot mounting

(optional)

(The shaft center of the bear-

ing unit does not align with

that of the Drive.)

(The parallelism of the

mounting beds is out of

allowable range.)

CONNECTING TO THE DRIVEN MACHINE

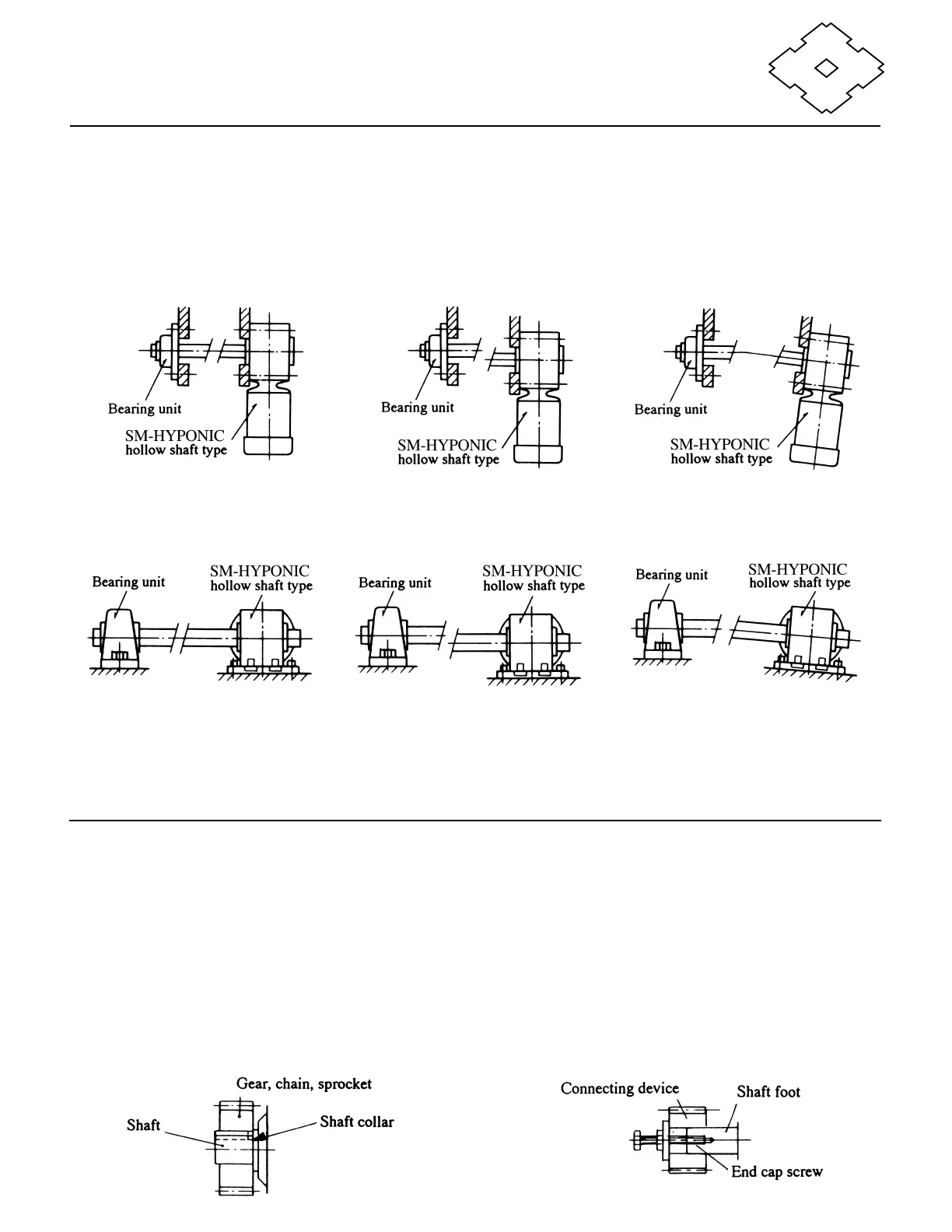

Solid-shaft type

1. Mount the connecting device, such as a coupling,

chain, sprocket, gear or V-pulley, on the shaft as

close as possible to the shaft collar. This places

the load point between the center of the shaft and

the shaft collar.

2. We recommend using end cap screws to avoid

possible bearing damage from excessive force or

thrust load that may be applied to the shaft while

fitting the connecting device.

3. When connecting the SM-Hyponic gearmotor to the

driven machine, be sure to align the shafts of both

units (for coupling connection) or keep both shafts

parallel (for chain, gear or V-belt connection).

4. Excessively loose chains will cause a jolt upon start-

up that may damage the SM-Hyponic gearmotor and

the driven machine. Excessive tension of V-belts

may cause bearing failure.

Fig. 12

Fig. 13

Loading...

Loading...