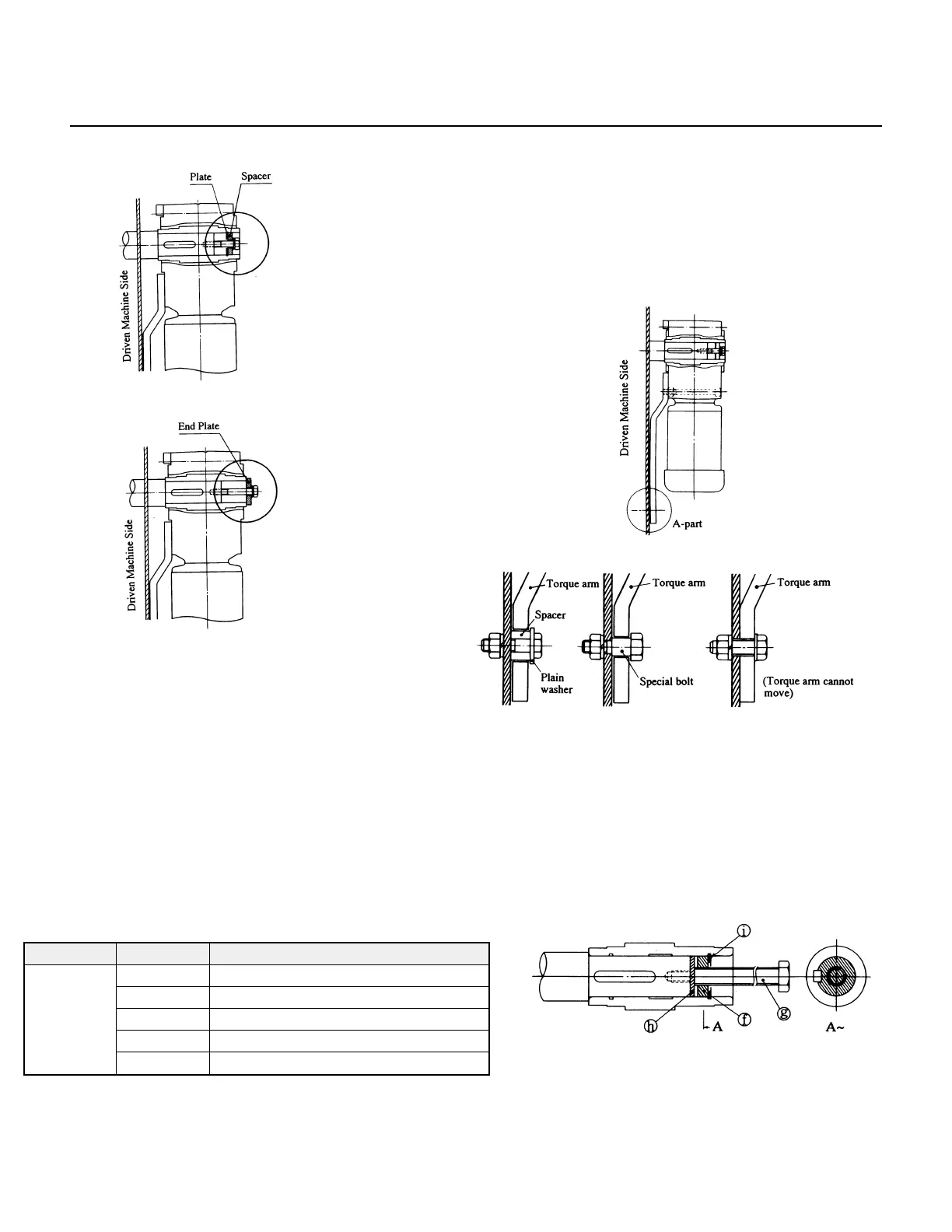

Fig. 5 Spacer and Plate Option

Fig. 6 End Plate Option

(c) Installing the torque arm.

Mount the torque arm on the driven machine side of

the drive casing. Use hexagon socket head bolts for

mounting. (See Table 2 for bolt sizes.)

Table 2

The torque arm (Section A in Fig. 8) should be mounted

to ensure that the contact surface between the drive and

shaft are free from excessive forces. Do not attach the

torque arm using anti-rotation bolts.

For applications that require frequent starts and stops or

frequent reversing, insert a rubber bushing between the

torque arm and securing bolt (or spacer) in order to

dampen impact load.

Fig. 8 Torque Arm Securing Methods

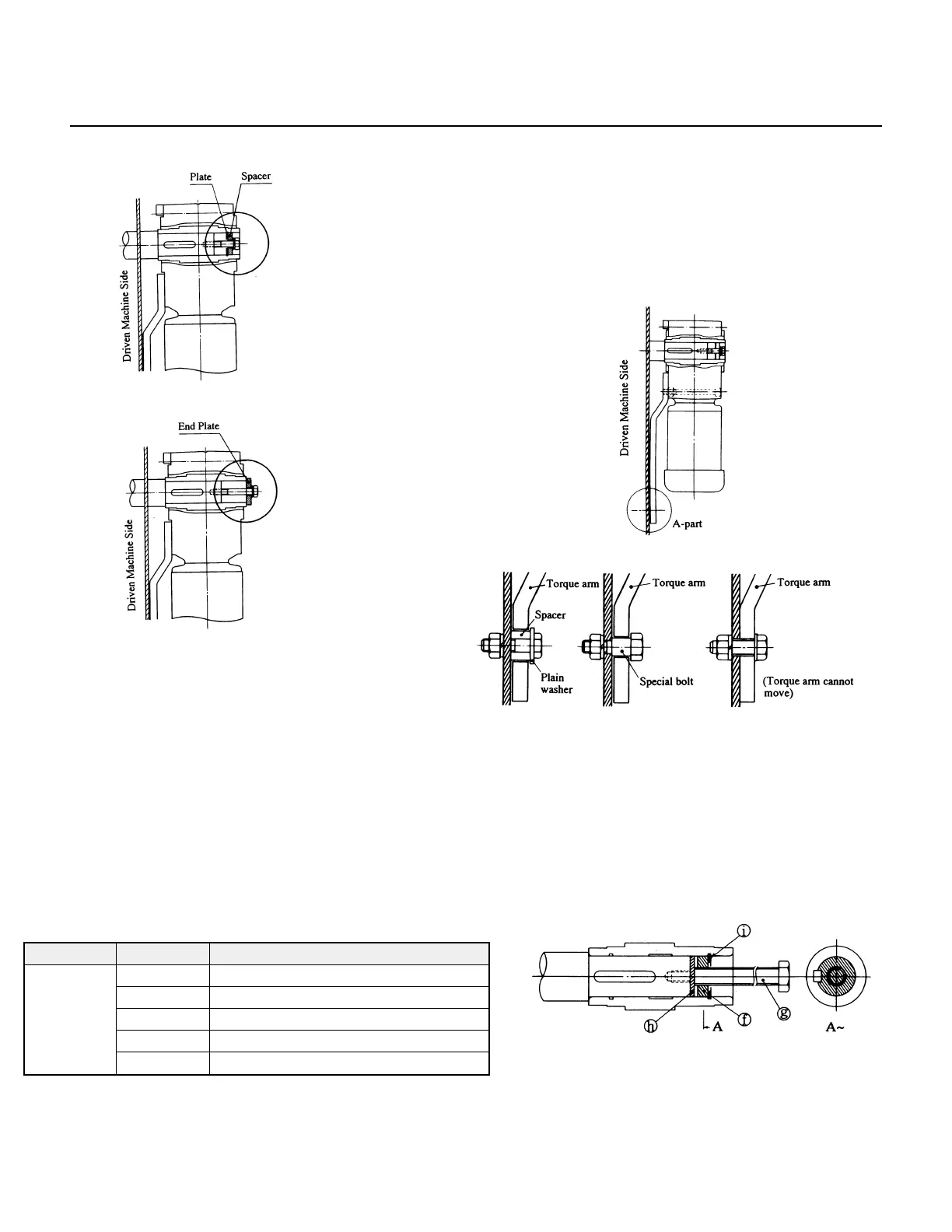

(d) Removing the shaft.

Do not apply excessive force to the gearmotor and shaft.

Using a jig as shown in Fig. 9 will facilitate removal of

the shaft.

Note: The customer should prepare parts for setting, securing or removing

the shaft.

Fig. 9

Series Frame Size Size of hexagon socket head bolt

20, 23 M8

30, 33 M10

RNFM 40˝, 43˝ M10

50˝, 53˝, 54˝ M12

60, 63, 64 M20

f – Spacer g – Bolt

h – Plate i – Shaft retaining C-ring

WARNING: Inappropriate installation may r

esult in shaft fretting.

Fretting will cause shaft wear, jamming, and misalignment between

the drive and Customer's

shaft.

Loading...

Loading...