- 9 -

- 20 -

Symptom Cause Remedial Action Prevention

Urine Odor

Around

Unit

Horizontal runs or

downward slopes

on pipe are causing

condensate to

block pipe.

Fan has failed (110

volt) (Electric and

AC/DC)

Fan has failed (12

volt) (AC/DC and

NE)

Device other than

Sun-Mar diffuser is

installed on top of

the vent stack

Room where unit is

located is airtight.

2” Vent stack has

too many bends

and/or horizontal

lengths. (Electric

and AC/DC)

Install wall brackets on vent pipe to

prevent settling. DO NOT install hori-

zontal runs as liquid will collect and

block ventilation, causing odor.

The fan is a constantly moving part

and has a finite service life.

The fan is a constantly moving part

and has a finite service life.

Wind turbines or vent caps

should not be installed on or, instead

of a Sun-Mar diffuser.

Install your CENTREX 2000 in an

area with plenty of ventilation and

watch for competing appliances such

as bathroom fans and wood stoves.

Install the vent with minimal bends

(total bends should equal no more

than 360 degrees) and NO horizon-

tal or downward slopes.

Installation

Considerat-

ions for the

waste pipe

The 3” Waste

Inlet

Drain

Installation

When installing the waste piping from the toilet to the composting unit, the following considerations

should be born in mind:-

i) The piping should be either 45 degrees or more to the vertical (if composting unit is directly below

toilet), or at a 2-3 degree angle (1/8”-1/4” or 3-13mm drop per foot maximum) so that the waste

travels with the liquid.

ii) Piping should not slope upwards at any point.

iii) Connections should be snug so that waste is not encouraged to “hang up” where pipe meets

connector.

iv) It is recommended that the waste pipe not be longer than 15 feet (460cm) without installing a clear

out port(a Y fitting with screw on end cap) near the toilet to provide easy access should it ever be

required.

v) Use a soft sealant, such as silicone for the connection of the waste piping to the composting unit so

that the composting unit can be moved for servicing or other reasons should this ever be required.

vi) Insulate piping if unit is to be used during the winter.

For heavy winter use, the composting unit will need to be kept warm by enclosing it, insulating the

enclosure, and providing some heat source. The enclosure must not be airtight since the unit

must be able to draw air in.

The 3”(75mm) waste inlet (supplied with kit) should be installed where the waste pipe feeds into the

composting unit. This assembly will allow the waste to flow into the Bio-Drum without interfering with the

drums’ function. If more room is needed in your installation, you can substitute this assembly by con-

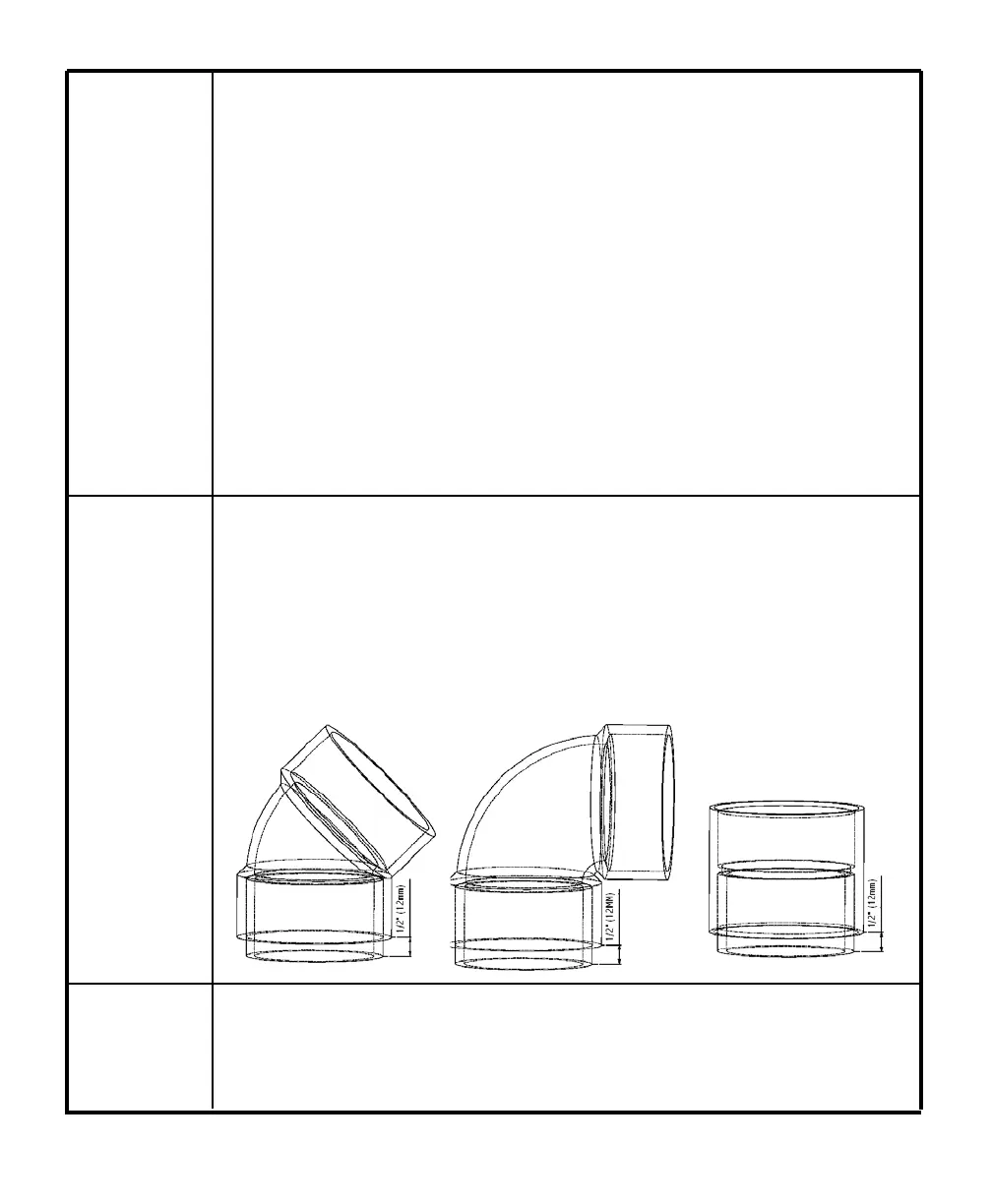

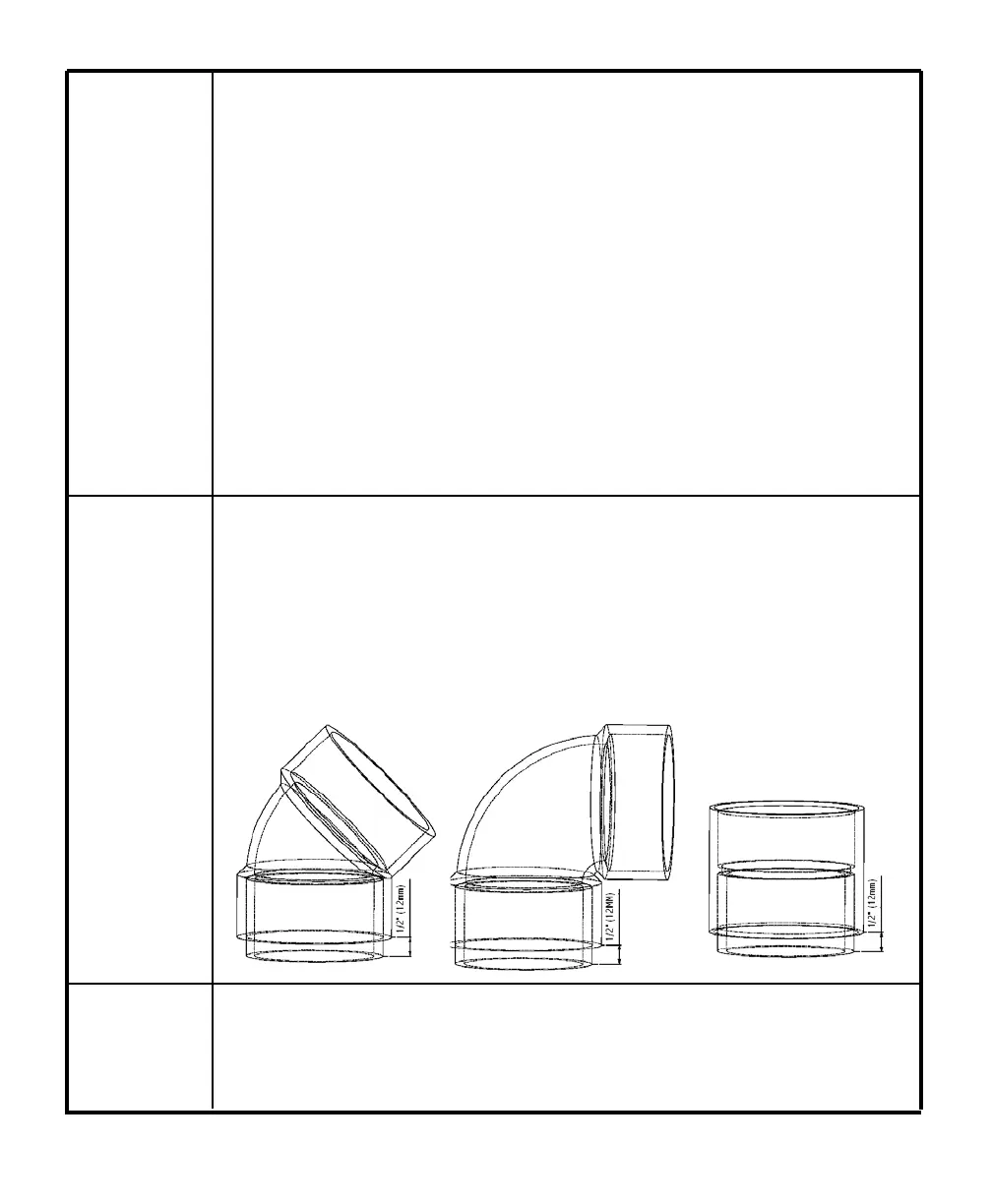

structing your own 3” (75mm) waste assembly from the examples shown below.

This assembly can be constructed by using a 3 (75mm)inch coupling or elbow (as shown below) and a

piece of 3 inch(75mm) pipe. Glue the pipe into the end of the coupling or elbow that will sit on the

composting unit waste inlet opening. Cut this pipe so that only 1/2”(13mm) protrudes from the coupling

or elbow. This pipe will fit in the waste inlet hole and should end just above the opening in the drum,

without interfering with drum movement.

The drains must be connected for all applications. The 1” (25mm)Safety drains at the left of the

“Centrex 2000”, exit to both the front and back. To connect one of the drains, (whichever is conven-

ient), remove the plug, attach the 1”(25mm) hose (included) and secure with a hose clamp. Ensure

there are no kinks or upward bends in the drain hose.

Re-install the vent so there are no longer any low

points where condensate can collect. If re-instal-

lation is not possible, drill a small hole in the bot-

tom of the low point (preferable outdoors) to

allow condensate to drain. (Note: watch for icing

in winter at this hole.)

Have your serial number ready and call Sun-Mar

for a replacement. Instructions are included with

the replacement fan.

Remove and replace fan. Fan should be on when

installed. When it is turned off it forms an

obstruction in the vent.

Wind turbines or vent caps may be discouraging

air movement. If so, replace with a Sun-Mar dif-

fuser.

1. Hold a lighter up to the air intake holes on the

back of the unit. Air should be drawn into

the holes. If air is not easily pulled in, check

venting for too many bends or horizontal

lengths and/or provide more ventilation to

the room.

2. Install fresh air intakes on any competing

appliances.

1. Re-install the vent stack to reduce the number

of bends/eliminate horizontal lengths.

2. If the vent stack cannot be further straight-

ened, remove the fan assembly and reduce

the amount of recirculating air by covering up

the area between the fan exhaust and the 90

degree vent intake elbow with duct tape or

similar.

Chapter 5

MECHANICAL TROUBLE SHOOTING

Most problems are prevented through proper maintenance and the use of proper bulking materials in the composting

unit. If you do have a problem, the Trouble Shooting section will help you solve it. If you still have further questions,

contact technical service at Sun-Mar for advice at 1-888-341-0782

Loading...

Loading...