Included

In Your Kit

Installing the

“1 Pint” Low

Flush Toilet

- 8 -

- 21 -

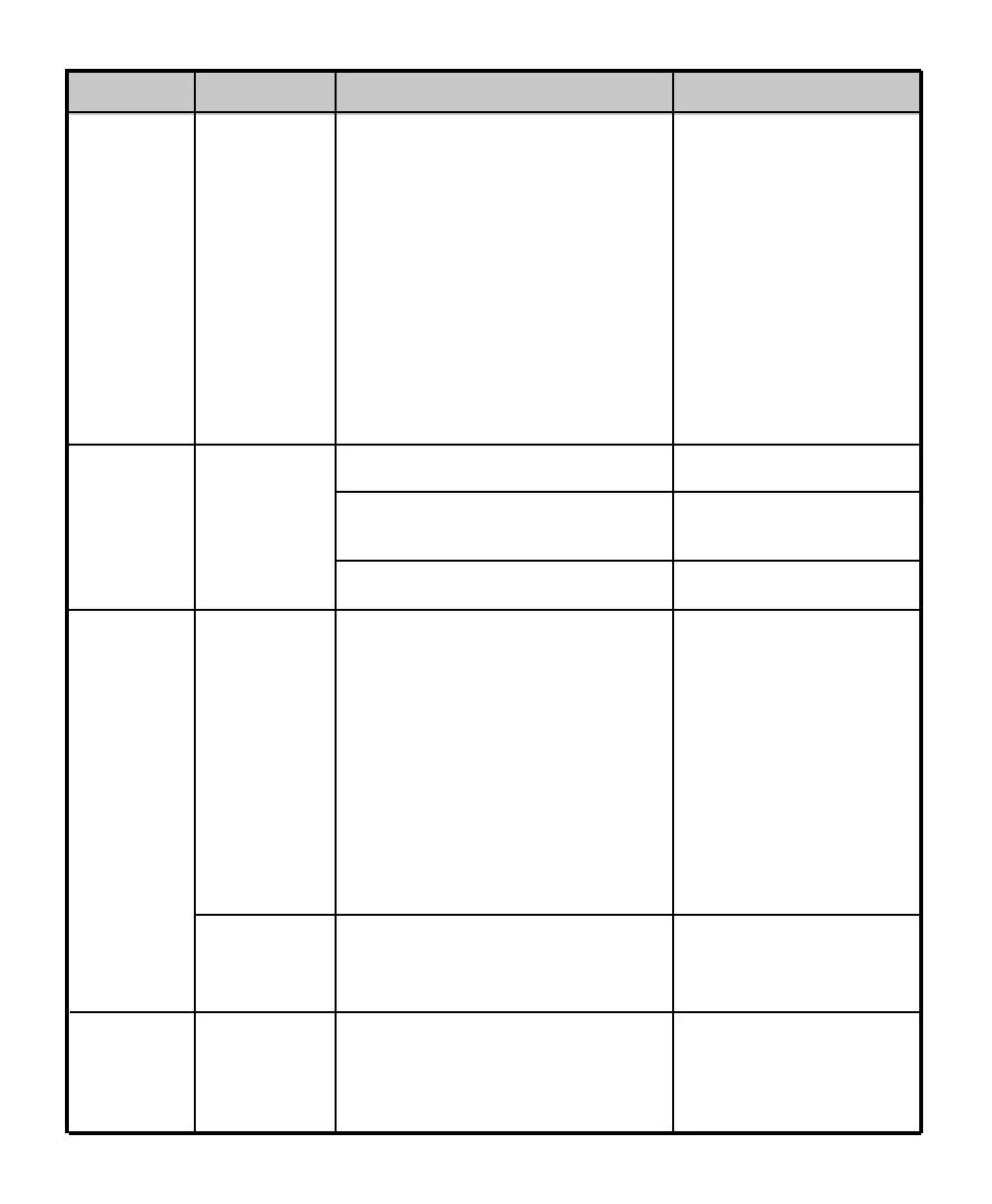

Symptom Cause Remedial Action Prevention

Occasional

Urine Odor

Outside

Strong

Sewage

Odor

Present

when drum

turns

Fan Noisy

(Electric

and AC/DC)

Fan Not

Working

(Electric

and AC/DC)

1. Vent stack not

installed even

with peak of roof.

2. If vent stack is

installed above

roofline, natural

obstructions,

such as tall

trees, being

located in a

valley or close to

a hill may be

causing down-

draft.

Compost is

anaerobic

Fan damaged in

shipping, or bear-

ings are beginning

to wear if it is rat-

tling.

Fan vibrations res-

onating in vent pipe

(12 Volt Fan)

Debris in fan or

Mechanical Failure.

1. Check that the vent is installed 2-3 feet (600-

900mm) above the peak of the roof. If not,

extend the vent.

Guide wires may be necessary.

2. Add lime to the evaporation chamber; as

much as you think necessary. You will have

to rake more often if you do this. You can

also add lime to the compost if desired, but

no more than 1/2 cup(250ml) per week as it

may upset the PH balance in larger amounts.

3. Sun-Mar has a filter box available which will

filter the ammonia out of the vented air in a

downdraft situation. Call Sun-Mar for details.

Drum too full.

Handle not turned enough.

Incorrect bulking mixture used

1. If it is rattling, it may need to be cleaned or

the bearings are worn and the fan needs to

be replaced.

2. A hum is the normal sound the fan will make.

If you are in a very quiet setting it will be

more noticeable. If this is the case, consider

purchasing a fan speed control so that the

fan may be turned down when the noise

bothers you.

3. If it is a vibration noise, you may need to tie

down the top of the stack with guide wires and

bracket the pipe that runs up the side of

the structure.

Use pipe clamps to secure vent pipe or install fan

with rubberized couplings to help absorb vibra-

tions.

Have your serial number ready and call Sun-Mar.

Downdraft is dependent on wind

direction, as well as natural

obstructions, etc.

Initially, install the vent 2-3 feet

(600-900mm)above the peak of

the roof. If symptoms occur, add

lime or a filter box.

Ideally, drum should be maintained

at 1/2 full.

Drum should be turned every sec-

ond day, 6 complete turns of the

drum (36-40 turns of the handle)

Use Compost Sure Blue or 100%

non-antibacterial wood shavings

Clean the fan with a small brush

and/or compressed air nozzle once

every 2-3 years in cottage use, or

once a year residentially. To do

this, remove the fan assembly by

taking off the snap cap covers and

unscrewing the screws which hold it

in.

The entire assembly will then simply

slide out. This will prevent wear

and lengthen the life of your fan.

The fan is a continuously moving

part which will eventually have to be

changed. Do Not turn on and off

daily.

1- Owners Manual 1- 1 1/2” (38mm)Roof Flashing (Electric & AC/DC)

1- Warranty Card 1- 4” (100mm)Roof Flashing (NE & AC/DC)

1- Evaporation Tray 6- 2” x 30” (50760mm)PVC Pipe (Electric & AC/DC)

1- 8’ 4” (254cm)Drain Pipe 2- Compost Sure

1- Rake 1- 4” Diffusor (100mm)(Electric & AC/DC)

1- 3” (76mm)Centrex 2000 Inlet 1- 6” (150mm) Diffusor (NE & AC/DC)

5- 4” x30” (100x 700mm)ABS Pipe (NE & AC/DC) 1- Centrex 2000 Hardware Kit

1- 12 Volt 2.4 Watt Fan (NE & AC/DC) 1- Centrex NE Hardware Kit (NE & AC/DC)

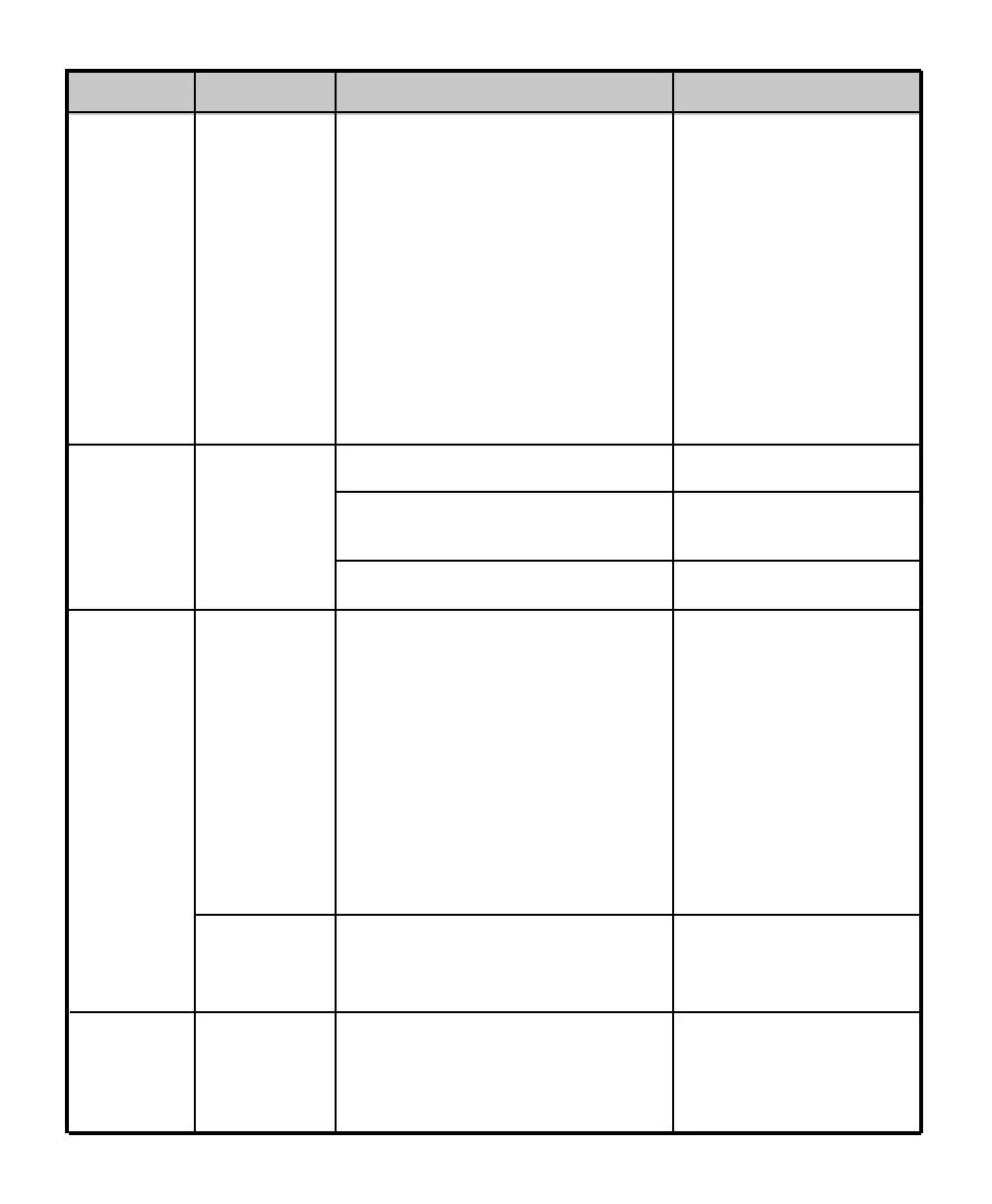

1. Make sure the center of the floor flange is at least 11 inches

(280mm) from the back wall.

2. When Installing a new floor flange, make certain that the toilet

mounting bolts align properly with Sealand Traveler toilet mount-

ing pattern.

3. Secure flange to floor using flat head screws through counter-

sunk holes in flange. Insert bolts into slotted holes in flange

(Fig. A)

4. If toilet is being installed in a shower stall, apply a 1/4”(6mm) thick

by 3/4”(19mm) wide bead of glazing compound around the

circumference of the floor flange (Fig B).

5. Position floor seal by pressing the floor bolts up through the

holes in the seal.

6. Set toilet in place with bolts protruding up through mounting holes

in base (Fig C).

7. Install washers and hex nuts provided with toilet. Tighten nuts

down equally with standard 7/17” (12mm) open end wrench.

Remove excess Glazing compound from around base.

8. Connect water supply line to water valve (1/2” or 13mm MPT) inlet

using appropriate fittings (Fig D)

9. Turn on water supply and flush toilet to test for leaks.

10. Attach pedestal and pedal covers to toilet base. See instructions

below.

Loading...

Loading...