26

ⓓ Loosen the base clamp②, adjust

the thread base③ up and down

that the interval between the

thread wiper and the needle

center can be 2.5mm when the

thread wiper and the needle center

are in a straight line, then tighten

the clamp②

ⓔ Loosen the thread crank clamp④,

adjust the thread wiper crank⑤

that the thread wiper under sewing

standby can have the interval of

15~17mm from the needle center,

then tighten the wiper crank

clamp④.

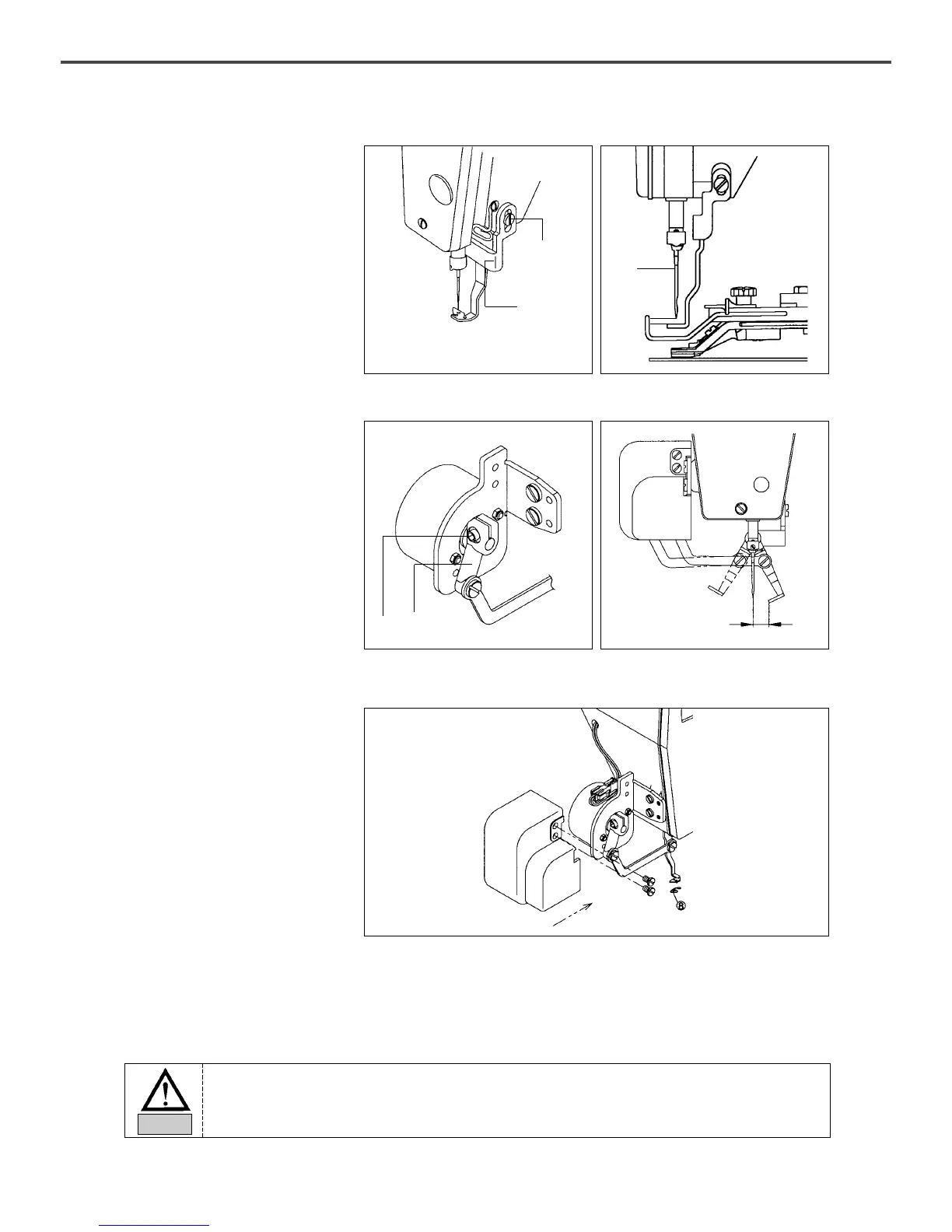

ⓕ Finally, after arranging the

connector as shown in the

figure48, attach the wiper cover

⑥ by using wiper cover joint

screw⑦.

ⓖ The thread wiper spring⑧ attached on the thread wiper base has the function to hold upper thread after

thread trimming, and its proper tension is about 20~30g. (A little stronger than the tension of lower thread

in the bobbin case)If the tension of the thread wiper spring is strong, the thread may come upward the

button.

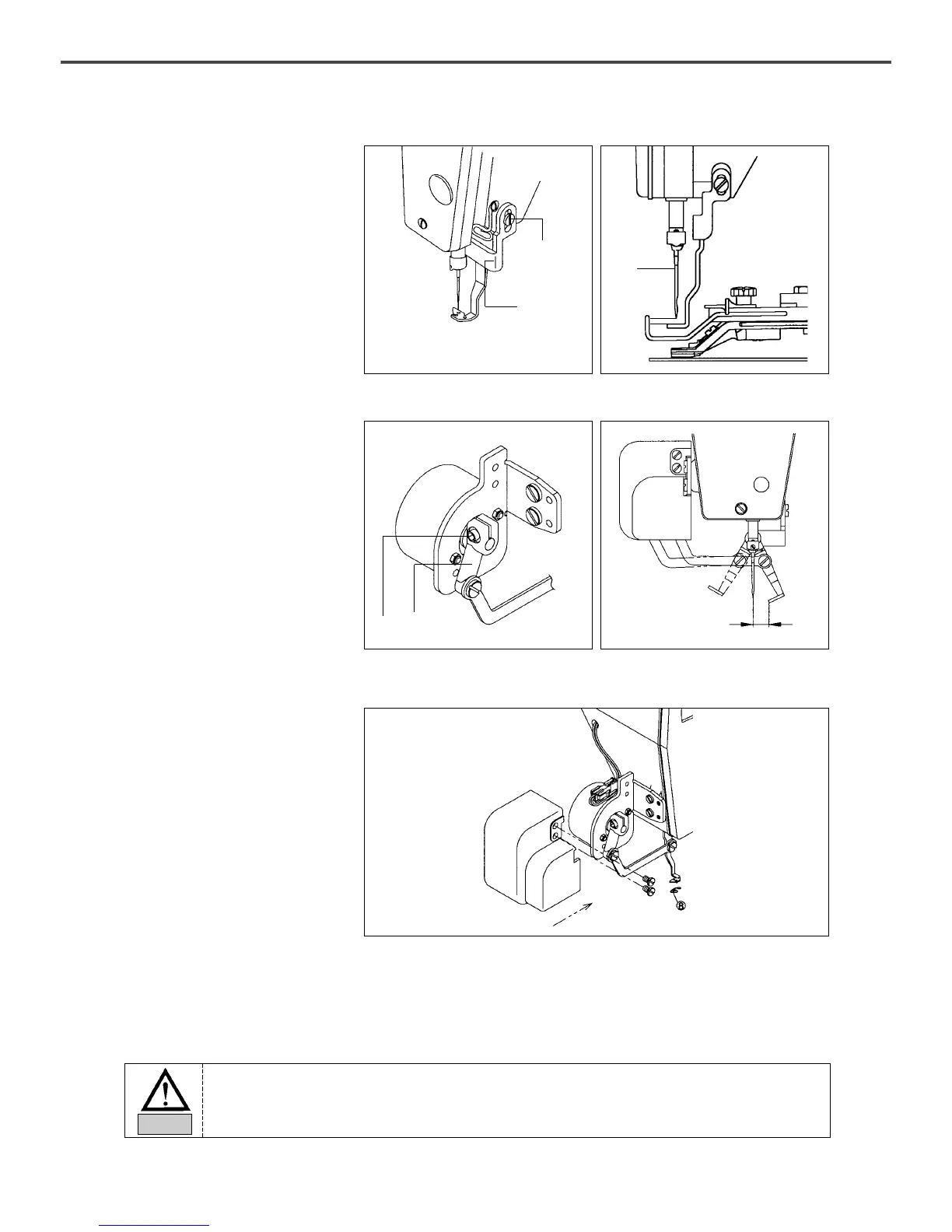

[ Fig. 44 ] [ Fig. 45 ]

[ Fig. 46 ]

[ Fig. 47 ]

[ Fig. 48 ]

②

①

2.5mm

③

④

⑤

15~17

To use the thread wiper solenoid, the sewing related function number, A-18 should be set up to

“100”. In addition to, check if A-14 is set up to “1”and A-31 to “0”.

Caution

Loading...

Loading...