General Information

900285-00 11/2014

Innovative Hearth Products

Superior

TM

DRT3000 Series Direct-Vent Gas Fireplaces

9

BTU Input

Table 1: Input Rate (BTU/HR), Gas Valves

Models

Natural Gas Propane Gas

High Rate Low Rate High Rate Low Rate

33” Models 14,000 10,500 13,000 9,500

35” Models 16,000 11,000 15,000 11,000

40” Models 20,000 14,000 19,000 14,000

45” Models 21,500 13,500 21,500 13,500

Table 2: Thermal Efficiency (%)

Model

Millivolt Electronic

AFUE * P4 ** AFUE * P4 **

33” Models 65 60 65 63

35” Models 66 61 66 63

40” Models 66 61 66 63

45” Models 67 61 67 63

* AFUE is a measurement of the US Department of Energy, ** P4 (EnerGuide) is a measurement of the Canadian Office of Energy Efficiency.

Efficiencies are based on Normal input operation.

Gas Pressure

Table 3: Inlet Gas Supply Pressure

Fuel Minimum Maximum

Natural Gas 5” WC / (1.25 kPa) 10.5” WC / (2.61 kPa)

Propane 11.0” WC / (2.74 kPa) 13.0” WC / (3.23 kPa)

Table 4: Manifold Gas Supply Pressure

Fuel Pressure

Natural Gas 3.5” WC / (0.87 kPa)

Propane 10.0” WC / (2.49 kPa)

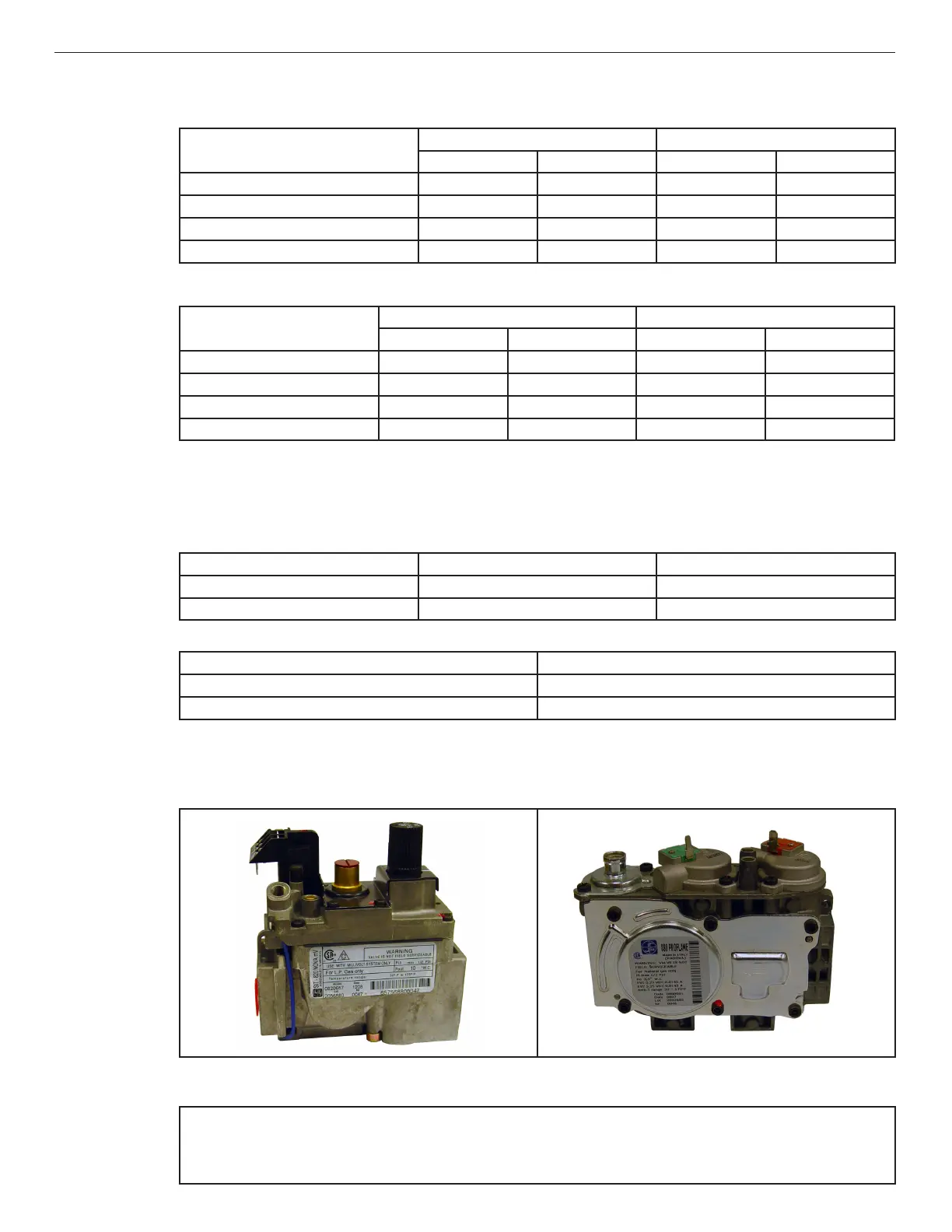

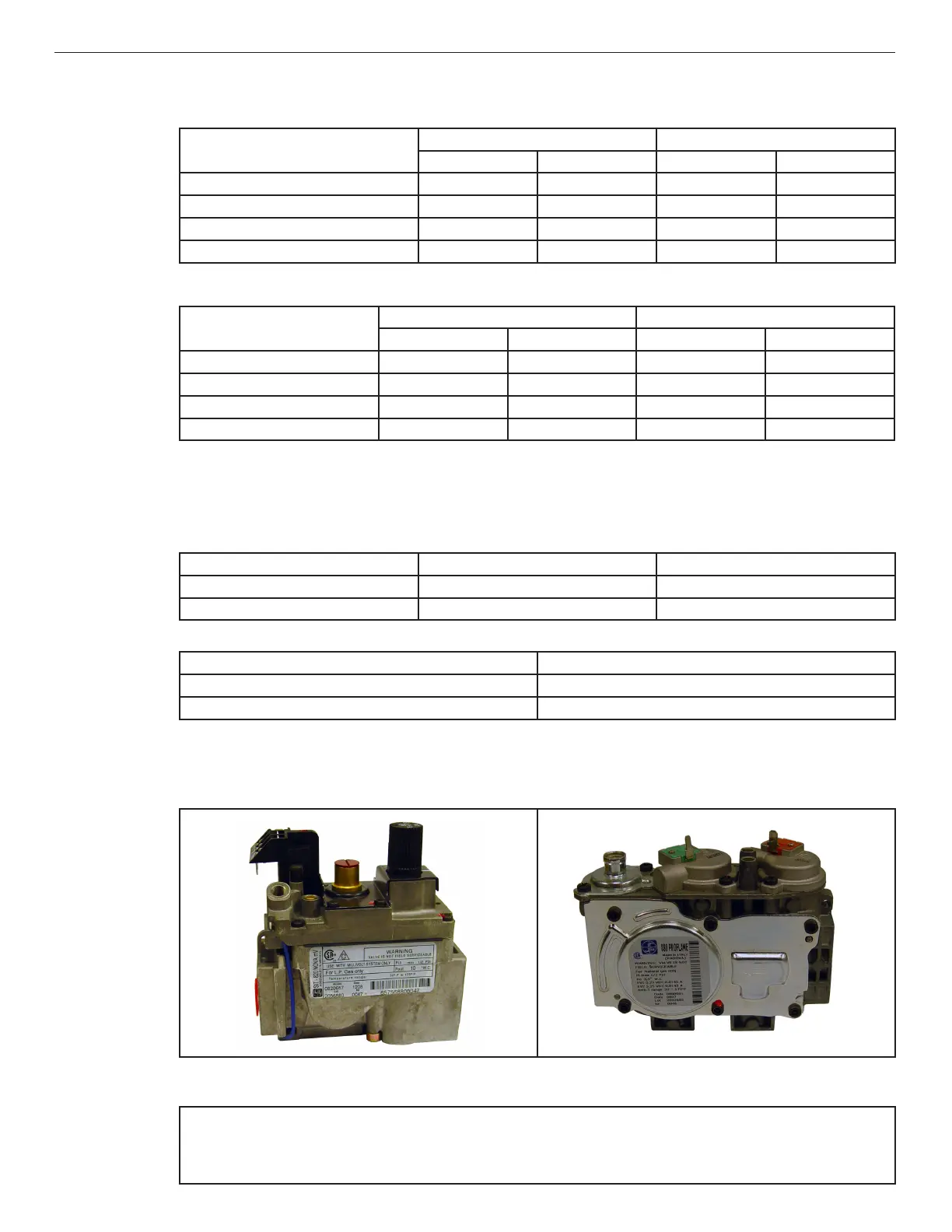

Test gauge connections are provided on the front of the millivolt and electronic gas control valve (identified IN for the

inlet and OUT for the manifold side). The control valves have a 3/8” (10 mm) NPT thread inlet and outlet side of the

valve (Figure 1 and Figure 2).

Figure 1: Millivolt Gas Valve Figure 2: Electronic Gas Valve

Propane tanks are at pressures that will cause damage to valve components. Verify that the tanks have step down

regulators to reduce the pressure to safe levels.

The appliance and its appliance main gas valve must be disconnected from the gas supply piping system during

any pressure testing of that system at test pressures in excess of 1/2 psi (3.5 kPa).

The appliance must be isolated from the gas supply piping system by closing its equipment shutoff valve during

any pressure testing of the gas supply piping system at test pressures equal to or less than 1/2 psi (3.5 kPa).

Loading...

Loading...