technical reference

46

SYNRAD OEM v30 Operator’s Manual Version 2

Interface connections

Table 4-4 DB-9 input circuit specications

Input Signals Input Device Type and Specications

PWM Positive High-speed optoisolator LED, forward voltage drop (Vf) 1.5 VDC

O state Vmax +0.8 VDC

On state Vmin +3.5 VDC @ 5 mA

On state (continuous) Vmax +6.7 VDC @ 10 mA

Frequency, max. 100 kHz

Laser Enable 5V logic input buer

O state Vmax +0.8 VDC

On state Vmin +2.0 VDC @ 0.2 mA

On state (continuous) Vmax +5.0 VDC @ 0.5 mA

Note: Do not apply a Laser Enable signal until the OEM v30’s internal +5 VDC power supply has

stabilized (approximately 200 ms after DC power-up).

Sample input circuits

Caution

possible

equipment

damage

The Interface A (DB-9) Laser Enable input is a direct 5V logic input.

Do not send a voltage signal to the Laser Enable input (Pin 9) until

DC power is applied; otherwise, the control board will be damaged.

Observe all 5V logic specications and precautions when integrating

OEM v30 inputs and outputs into your control system.

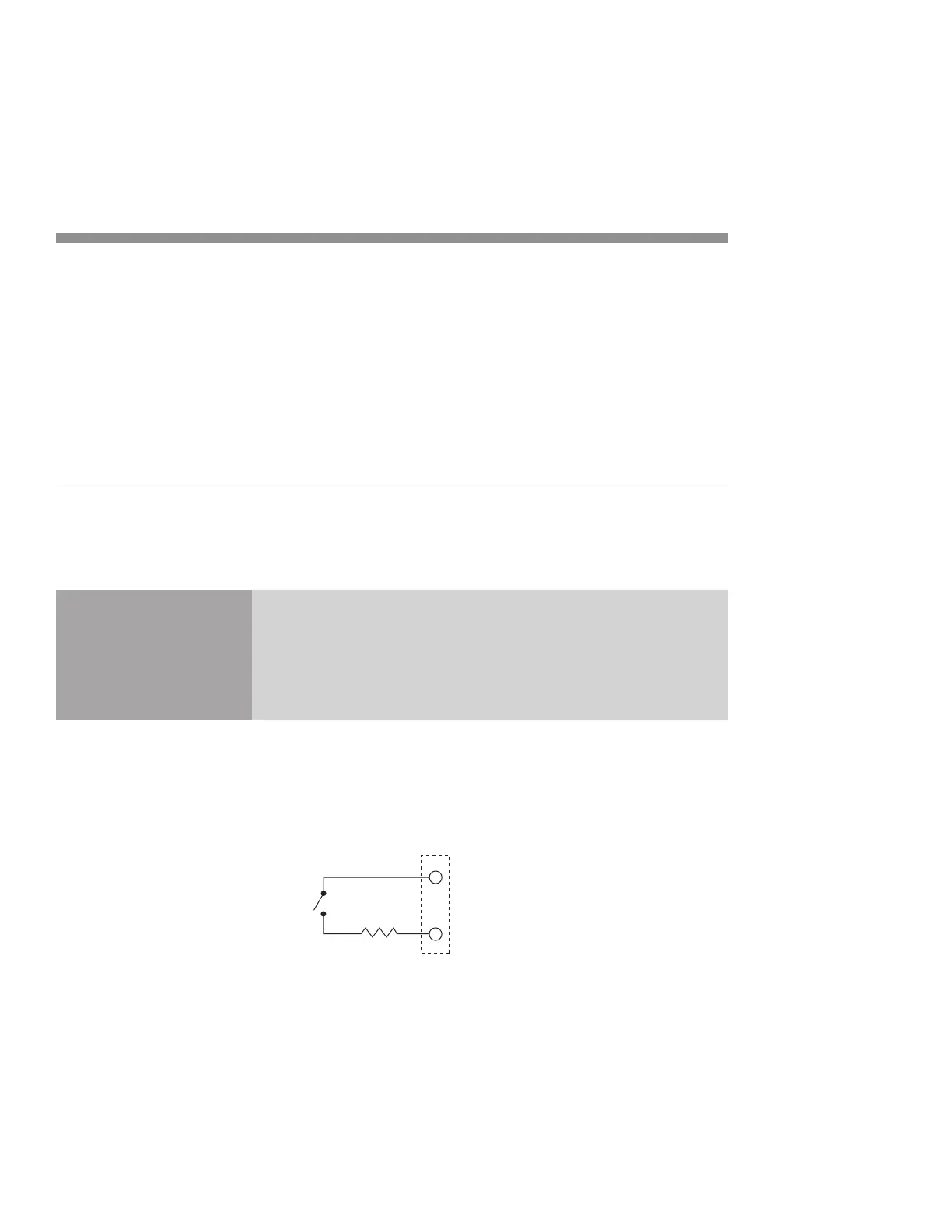

Figure below illustrates one method of applying the Laser Enable signal using a customer-

supplied limit switch or relay contact powered by the OEM v30’s DC Out output (+5 V, 250

mA).

Laser enabled when

switch or contact closed

DB-9 (INTERFACE A) CONNECTOR PINS

(5) DC OUT

(9)

100 Ohm

Figure 4-6 OEM v30 powered Laser Enable circuit

Loading...

Loading...