Air Chiller System (ACS) and Chiller Panel Getting Started Guide for the DMA 850 Page 17

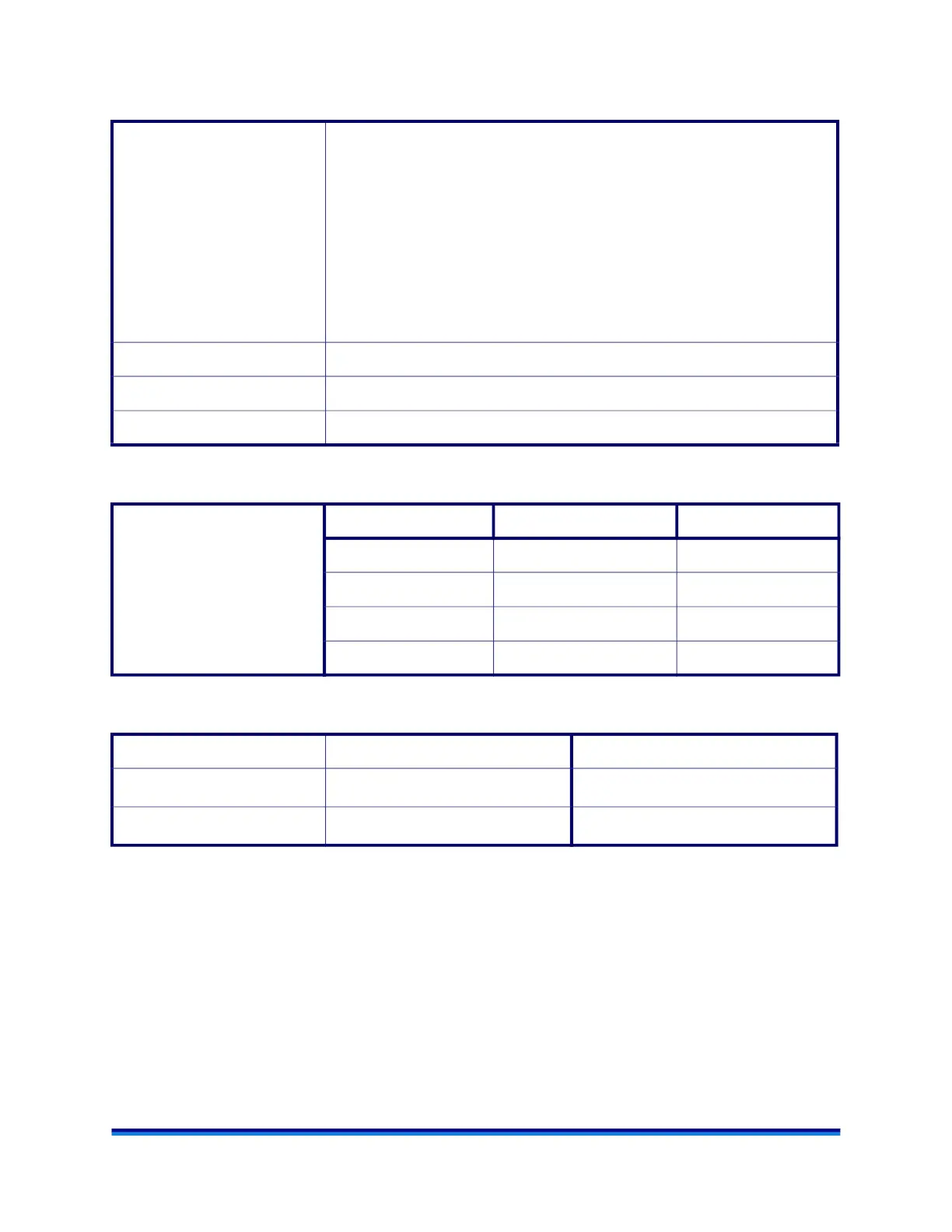

Table 4: Accessory Operating Environmental Conditions for ACS-2 and ACS-3

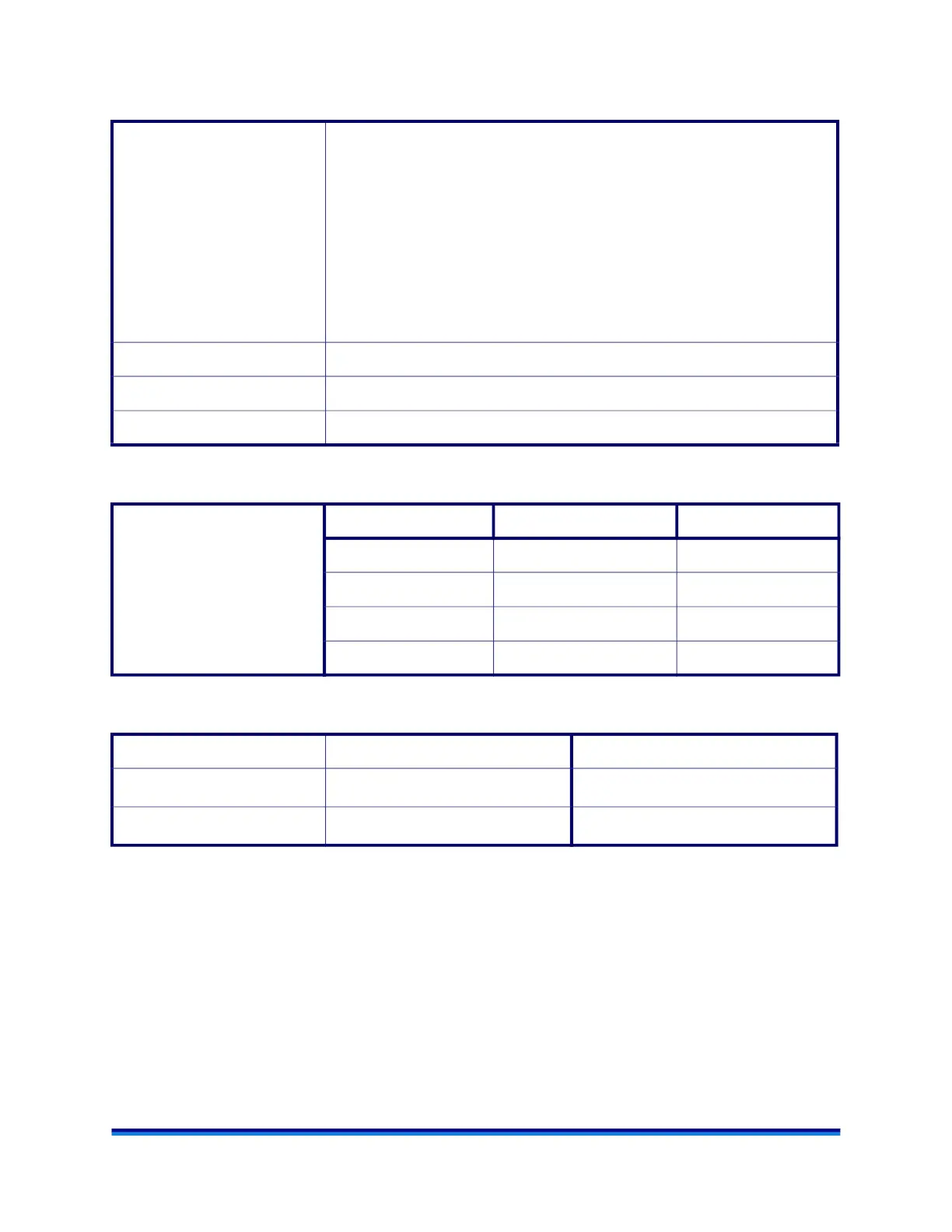

Table 5: Accessory Power Requirements for ACS-2 and ACS-3

Table 6: Accessory Performance Specifications

Ambient air 21°C–24°C = Ideal

NOTE: The ACS generates a significant quantity of heat when running. These

operating temperatures must be maintained during system operation.

Heat Generation:

ACS-2 50 Hz: 1450 W

ACS-2 60 Hz: 1450 W

ACS-3 50 Hz: 1750 W

ACS-3 60 Hz: 1600 W

*Refer to the serial number plate on the rear of the unit.

Operating altitude 2000 meters maximum

Relative humidity 5% to 80% RH from 15°C to 30°C

IP Rating The degree of protection for this instrument according to EN 60529 is IP20.

Electrical

*Refer to the serial number

plate on the rear of the unit

Part Number Voltage Frequency Current

405000.901 240V 60 Hz 9A

405000.902 220-230V 50 Hz 11A

405001.901 240V 60 Hz 8A

405001.902 220-230V 50 Hz 9.1A

Specification ACS-2 ACS-3

Lowest temperature

1

1. Lowest temperatures specified are achievable under ideal operating conditions. Actual temperature limits

will vary with ambient and compressed air temperatures and testing conditions.

-50°C

1

-100°C

1

Cooling rate:

see below

2

see below

2

2. Ramp Rate: The maximum sustainable ramp rate will depend on a number of factors particularly the start

and end temperature. To determine the maximum sustainable heating/cooling rate, perform the following

test and analysis:

a. Equilibrate to start temperature. Perform a time sweep or peak hold test with the temperature set (if

possible) to a few degrees in excess of the end temperature. Set the time much longer than you expect;

the test can be aborted when the temperature has reached a stable value.

b. Plot a graph of temperature vs. time (min) and take the derivative. Inspect the derivative curve over

your temperature range of interest. The maximum sustainable rate will be the lowest value on the de-

rivative curve.

Loading...

Loading...