CHARACTERISTICS OF ABRADING

WHEELS

The choice of which Genuine Taber abrading

wheels to use is best determined by preliminary

testing on the material to be investigated. The

abrasive action of the testing wheel should

reproduce, as nearly as possible, the wear that

the material will receive in actual use. It is

important to keep in mind that wear is a complex

phenomenon that may not be exactly replicated

through an accelerated abrasion tests.

Abrading wheels for the Taber Abraser can be

classified as:

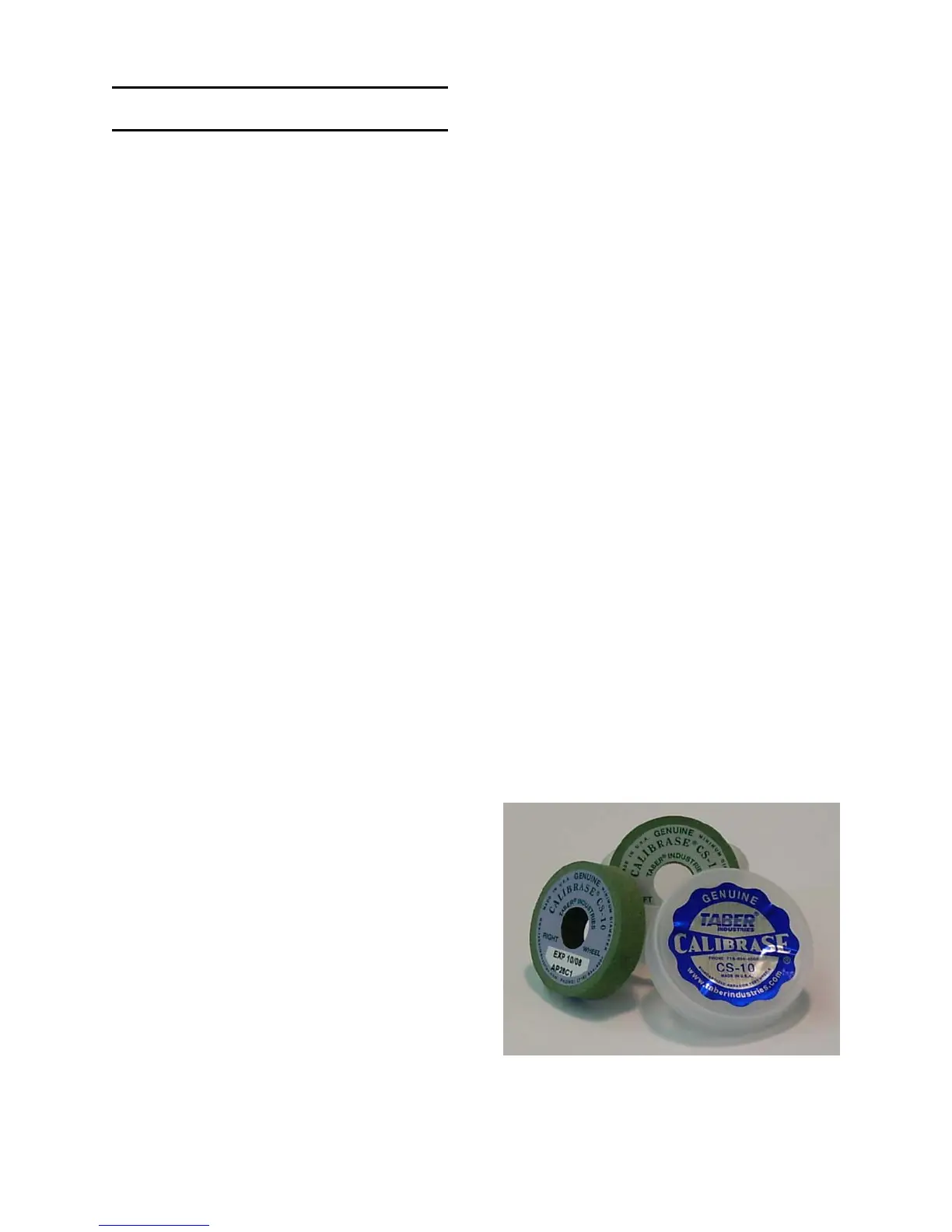

Calibrase

®

– A resilient wheel composed of

resilient binder and aluminum oxide or silicon

carbide abrasive particles. Frequently used

to evaluate rigid specimens.

Calibrade

®

– A non-resilient wheel

composed of a vitrified (clay) binder and

silicon carbide or aluminum oxide abrasive

particles. Frequently used to evaluate

flexible specimens.

Specialty – Used for special applications.

For both Calibrase and Calibrade wheels,

different grades are furnished to meet varying

requirements of abrasive action. During testing,

the wheel surface gradually wears away

exposing new abrasive particles. The minimum

usable diameter of Taber abrading wheels is 1-

3/4 inch, which corresponds with the wheel

label.

The composition of Genuine Taber abrading

wheels has been carefully chosen to reproduce

normal service wear. The quality and uniformity

of these wheels is maintained by continuous

inspection sampling and tightly controlled

manufacturing processes.

NOTE: The wear life of Calibrase or Calibrade

wheels will vary based on the load, surface texture

and frictional characteristics of the material tested and

frequency of refacing.

NOTE: The abrasive coefficient of the wheels can be

altered by oil or other contaminants. Handle only the

sides of the wheels.

U WARNING: Shelf life is dependent on proper

storage conditions (temperature 23°C±2°, relative

humidity 50 ±5%). When not in use, store

abrading wheels in their original container.

Calibrase Wheels

CS-10F Calibrase – A resilient wheel that offers

a mild abrading action, and was designed to

operate under loads of 250 or 500 grams. The

CS-10F is typically used to test materials such

as safety glazing materials and transparent

plastics, and must be refaced with the ST-11

refacing stone.

CS-10 Calibrase – Similar to the CS-10F, this

resilient wheel offers a mild – medium abrading

action like that of normal handling, cleaning, and

polishing. This popular wheel has been used to

evaluate a variety of materials including organic

coatings, plastics, textiles, leather and paper

products. Reface with the S-11 refacing disc.

CS-10P Calibrase – The abrasion rate is the

same as the CS-10, but this wheel has been

engineered so the wheel surface does not load

when testing paper products. Intended for tests

of short duration, with refacing after every tenth

test.

CS-10W Calibrase – This wheel is the same as

the CS-10 but white, to eliminate any color

transfer from the wheel to the specimen.

CS-17 Calibrase – Compared to the CS-10

wheel, the CS-17 produces a harsher abrasion.

Normally operated using loads of 500 or 1000

grams, this wheel is useful for testing materials

such as ceramics, plastics and enamels.

Reface with the S-11 refacing disc.

NOTE: Custom formulations can be developed

specific to your application.

U WARNING: Because of possible deterioration,

Calibrase wheels should NOT be used after the

expiration date printed on the wheel.

Figure 55

22 5135 / 5155 Operating Instructions ver 1.1

Loading...

Loading...