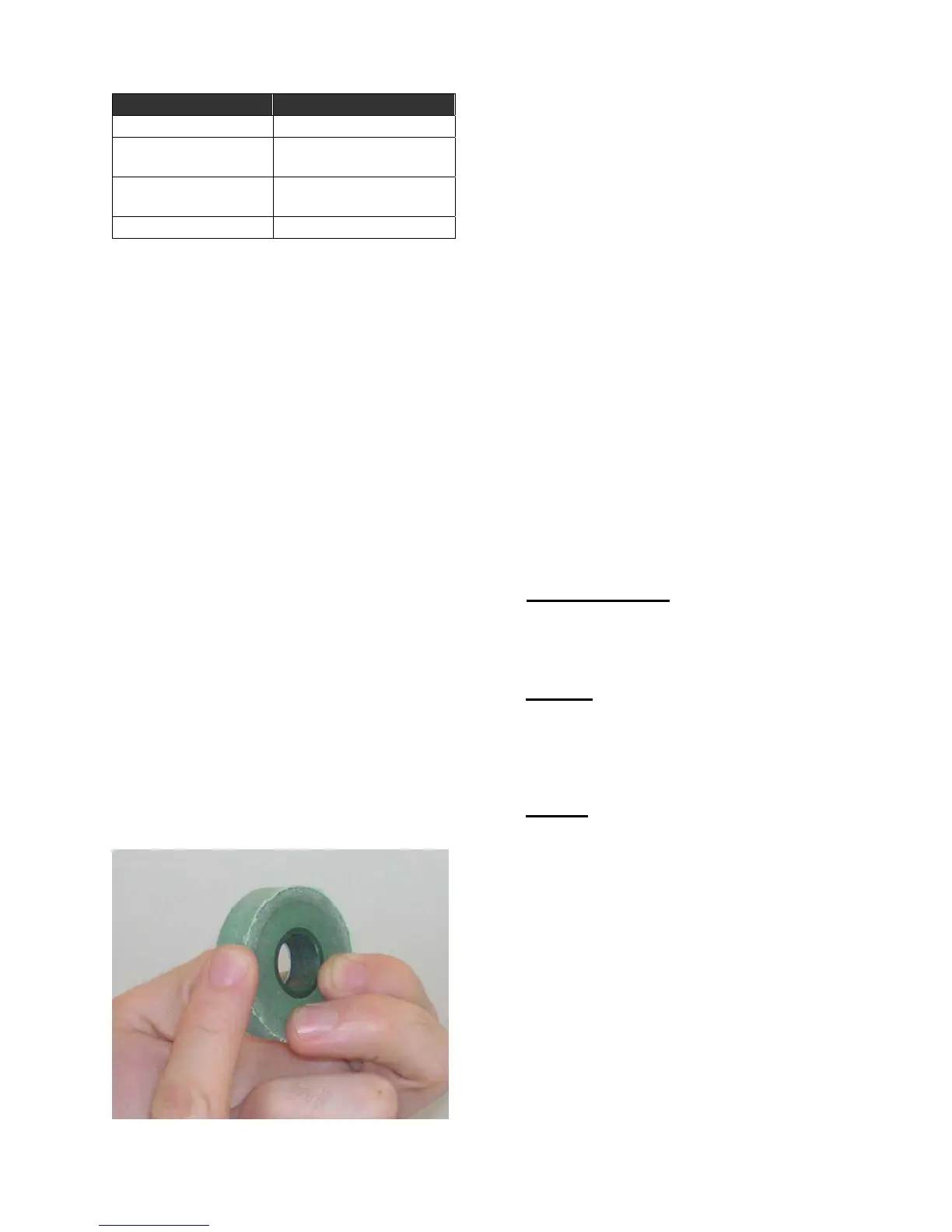

TABLE 1

Wheel Status Refacing Cycles

New 2 refacings of 50 cycles

Used (previous test

<1,000 cycles)

25 cycles

Used (previous test

>1,000 cycles)

50 cycles

* During Test 25 cycles

NOTE: When refacing CS-10F wheels, adjust the

vacuum pick-up nozzle to 0.79 – 1.59 mm (0.0312 –

0.625 inch) above the ST-11 refacing stone.

NOTE: Properly refaced wheels must contact the

specimen their full width. Refacing can be checked

visually, wheel color should be uniform after two

refacings of 50 cycles each. If it is not, reface the

wheels a third time.

U WARNING: Do not reface Calibrase wheels by

placing a S-11 refacing disc over the specimen.

Mounting on top of a specimen may cause the

surface of the S-11 not to run absolutely true,

which would abrade a slight crown on the wheel

faces causing inaccuracies.

Wear Characteristics of Calibrase Wheels

Resilient wheels possess properties that cause

the working faces to disintegrate slowly as they

are used, continually exposing fresh abrasive

grains to the specimen being tested. This

characteristic is necessary for the proper

functioning of the Abraser.

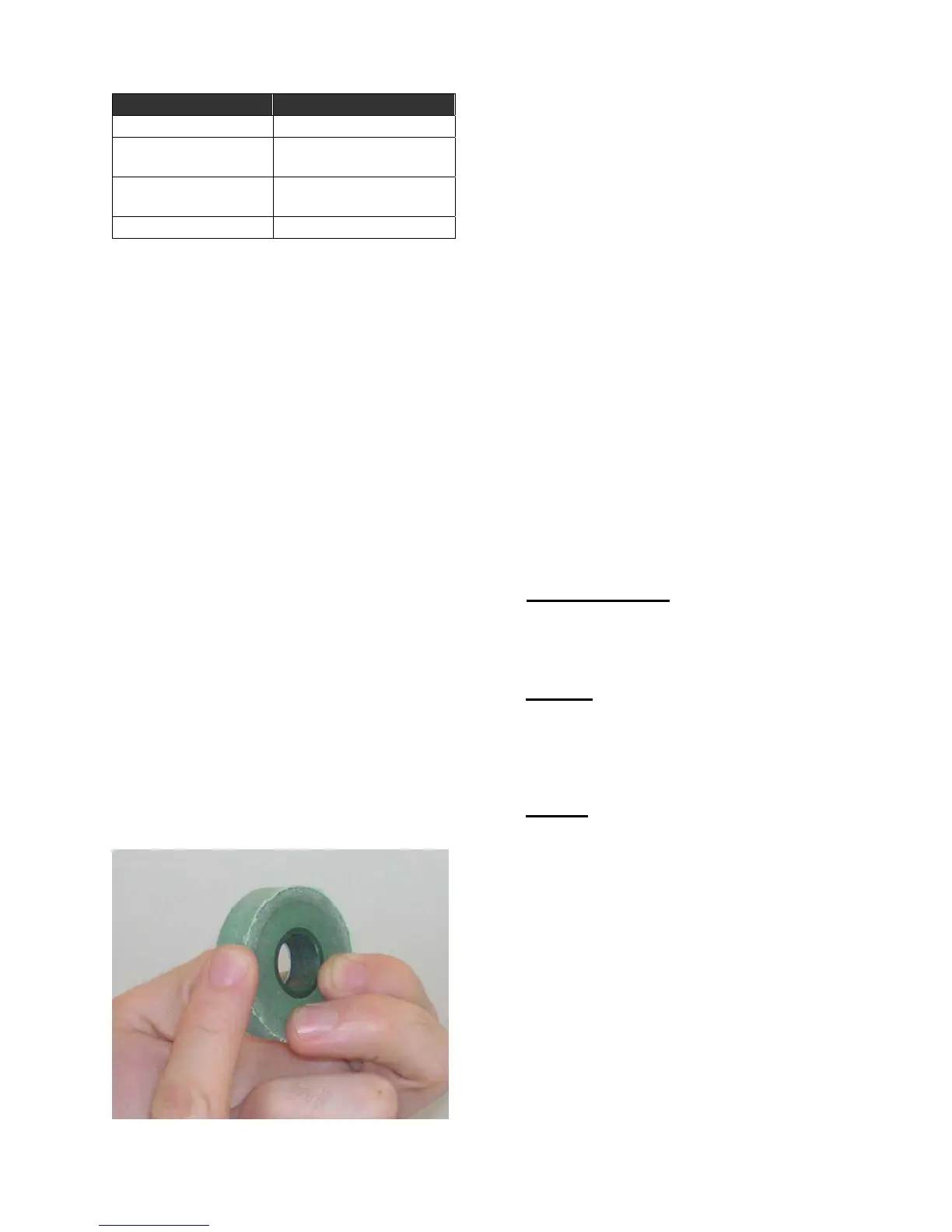

A thin film of rubber may form on the left hand

edge of Calibrase wheels as the main body of

the wheel wears down (Figure 64). Although a

narrow fin is not detrimental to the test, should it

extend more than 1.59 mm

(0.0625 inch) beyond

the work surface, remove it by gently rubbing the

edge with your finger. Do not rub excessively so

as to round the edge of the wheel.

Figure 64

Wear life of Calibrase wheels varies with the

surface texture and frictional characteristics of

the material tested, in addition to the load.

Under ordinary conditions Calibrase wheels

should give from 10,000 to 50,000 wear cycles.

Abnormally short wheel life indicates use of the

wrong wheel, load, or procedure for the material

tested, or too frequent refacing.

U WARNING: The abrasive coefficient of the

working faces of the wheels can be altered by oil

or moisture from the fingers. Touch only the sides

of wheels in handling.

Refacing Vitrified Wheels (Calibrade)

All Calibrade wheels are diamond trued at the

factory and may be used continuously without

further refacing until the abrading surfaces show

indications of becoming worn out of round,

crowned or clogged with abraded material.

Refacing is also advised when starting a series

of comparative tests or changing to an entirely

different material. In some instances, where

there is a tendency for the working surfaces of

the wheels to pick up excess material, it may be

desirable to reface the wheels before testing

each specimen. (This latter procedure is only

required in exceptional cases.)

A. Worn out of round

– Occasionally, wheels

become out of round due to unevenness of the

specimen being abraded or other reasons. The

normal abrading surface of these wheels should

be concentric with the hub.

B. Crowned

– The working surfaces of wheels

that are “crowned” appear slightly rounded. To

check for this condition, place a straight edge

against the two wheels. The straight edge

should be in contact with the full width of the

wheels.

C. Clogged

– “Clogging” can be identified as a

spot buildup on the working faces of the wheels

and should not be confused with the uniform

coloring of abrading dust from the specimen.

Procedure for Refacing Calibrase Wheels

To properly reface Calibrade wheels, a Taber

Wheel Refacer must be used. This instrument

utilizes a diamond tool that is traversed across

the working surface to precision dress the

abrading wheels (Figure 66).

Refacing Calibrade wheels leaves a sharp edge

that may sever threads when testing textile

fabrics. It is acceptable to remove this sharp

edge prior to testing. To do so, cut a small strip

from an S-11 refacing disc and hold it lightly

against the outer edge of each wheel. Manually

turn the nut to rotate the motor shaft. Reverse

26 5135 / 5155 Operating Instructions ver 1.1

Loading...

Loading...