Figure 69

Wood (S-17) – S-17 plaques (Figure 70) are

manufactured from grade A1, 6.35 mm

(0.25 inch)

birch plywood. Sanded on both sides, the size

is 100 mm

(4 inch) square with a 6.35 mm (0.25

inch)

center hole.

Figure 70

Aluminum (S-18) – Produced out of #19 gauge

5052 aluminum, S-18 plates (Figure 71) are 100

mm (4 inch) square with rounded corners and a

6.35 mm

(0.25 inch) center hole.

Figure 71

Glass (S-31) – The S-31 is a quality plate glass,

approximately 3.17 mm

(0.125 inch) in thickness

with a 6.35 mm

(0.25 inch) center hole.

Panels dipped or sprayed on both sides should

be marked with an “A” or “B” to identify the front

and back surfaces and their respective tests. An

extra heavy application may not dry with the

same physical properties as a light coating.

When preparing your own test panels, ensure

the sides are flat and parallel. A simple means

to check for flatness is to place a straight edge

across the test panel surface, and verify there is

no gap. Use a file to remove any burrs from the

center hole and edges.

• To generate useful data, specimens must be

flat and have a uniform coating thickness.

• To subject specimens to a wet abrasion test,

the Rimmed Specimen Holder (E140-75)

may be used. This holder has a 9.5 mm

(0.375 inch) raised rim for retaining liquids

during test. Such tests might include paint

used to mark traffic lanes at busy

intersections, subjected to both wet and dry

abrasion in everyday use.

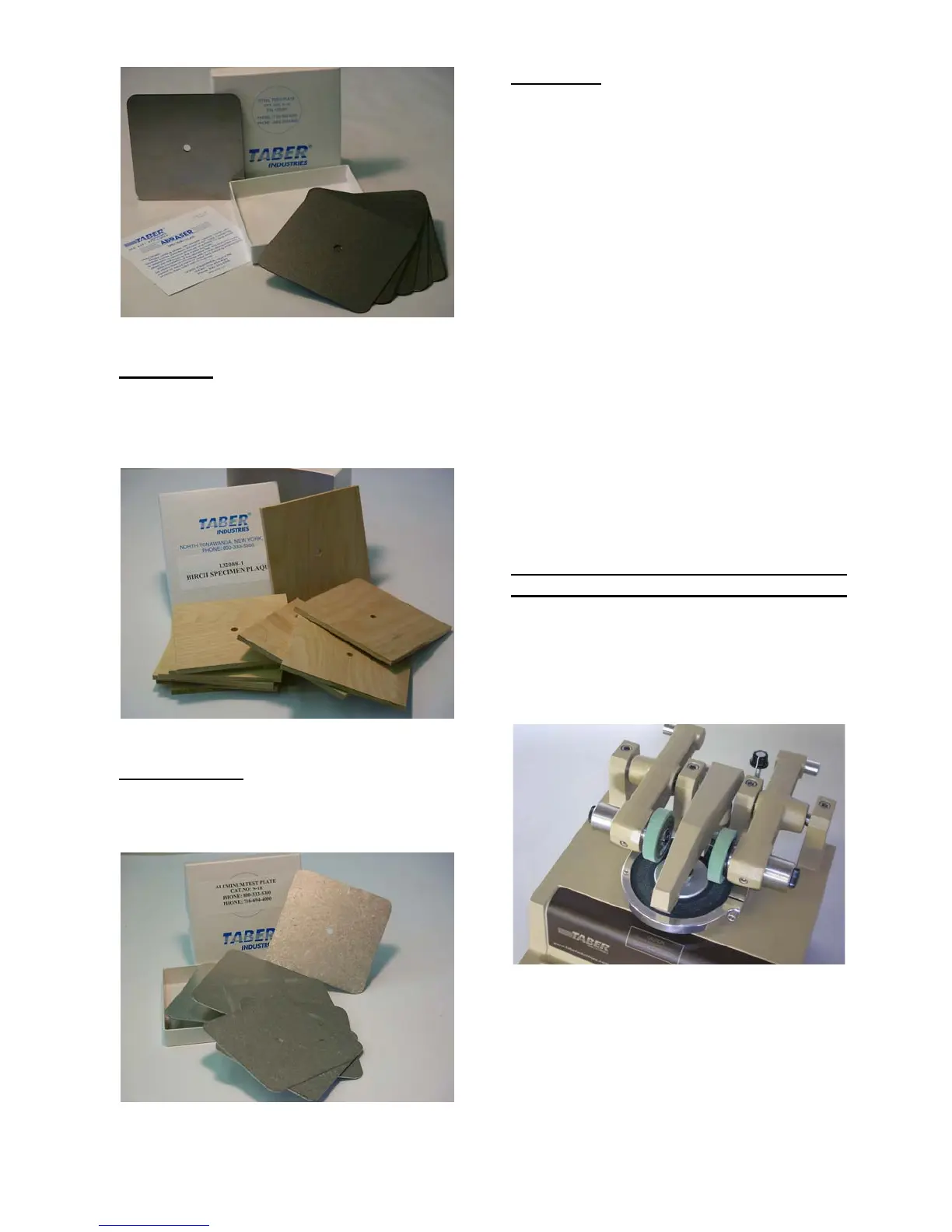

TEST PROCEDURES

The following suggestions are provided as a

starting point for using the Taber Rotary Abraser

to evaluate different materials. See page 47 for

a partial listing of internationally recognized test

methods that reference the Taber Abraser.

Figure 72

Prior to conducting any tests, the abrading

wheels should be prepared accordingly and a

consistent vacuum nozzle height should be used

(measured off the specimen surface). Other

factors to consider include specimen

conditioning, environmental conditions, vacuum

suction level, specimen cleaning, and test

cycles. Specimens must have a flat, even

surface and run true.

33 5135 / 5155 Operating Instructions ver 1.1

Loading...

Loading...