Wheels and Load: CS-10 Calibrase with 250

gram or 500 gram load.

Evaluation

: Visual changes (i.e. loss of luster;

changes of surface; etc.); weight loss method.

Remark: Duration of the test is a predetermined number of

cycles (i.e. 300, 500 or whatever number is needed to reach

the degree of wear to be regarded as the end point of the

test). The loss in milligrams is calculated on a 1000 cycle

basis which gives a Taber numerical wear index directly

comparable with that of similar materials tested under the

same conditions.

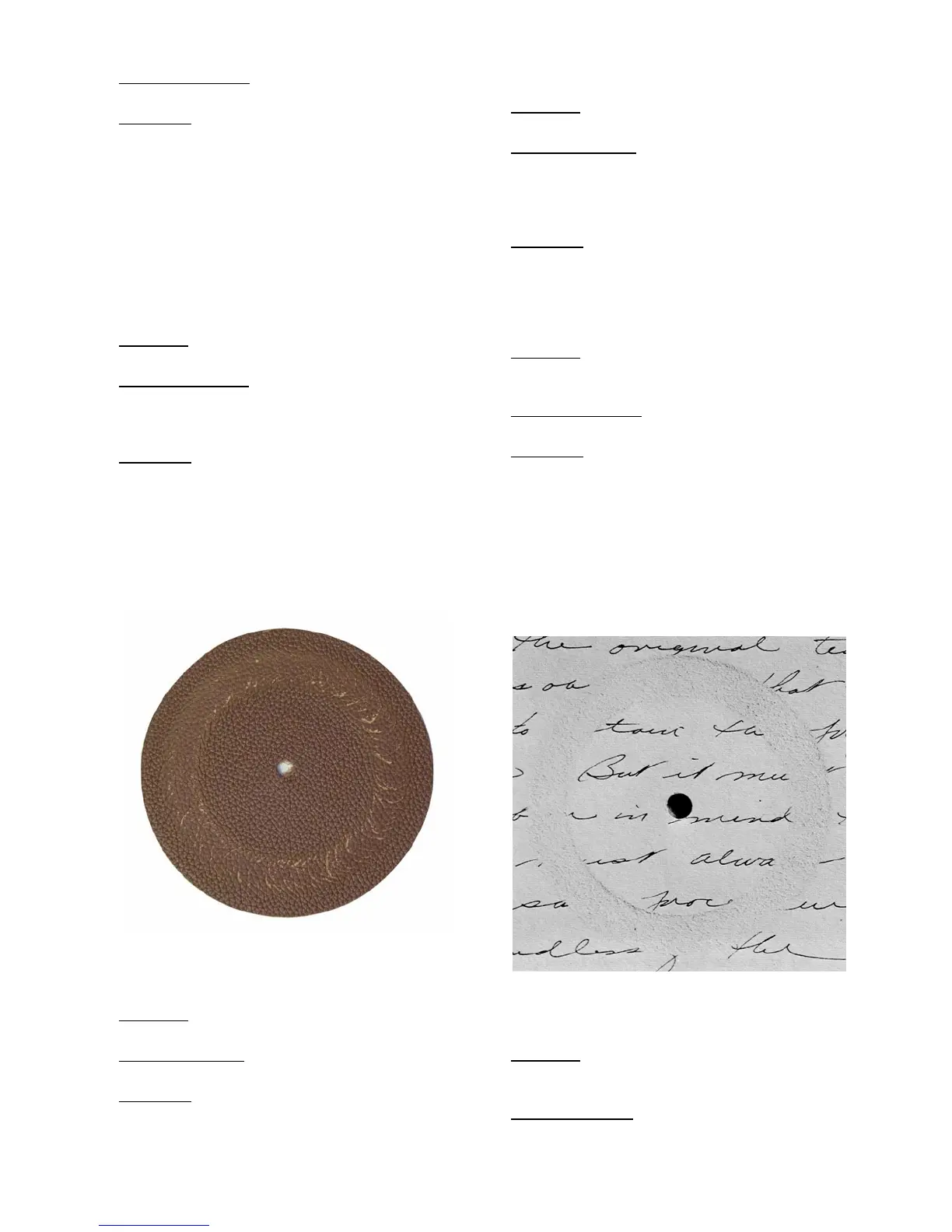

Leather Coverings – Luggage and

Upholstery (Figure 75)

Specimen: 100 mm (4 inch) diameter or square

with 6.35 mm (0.25 inch) center hole.

Wheels and Load

: CS-10 or CS-17 Calibrase

with 500 gram or 1000 gram load. Alternatively

use H-18 or H-22 Calibrade with 1000 gram

load.

Evaluation

: Weight loss method, visual changes

(i.e. loss of luster; changes of surface; color

changes; breakthrough of top coat).

Remark: H-22 Calibrade wheels can be used on the more

durable grades of leather subject to harsh wear; dyed,

surface colored leather may require less severe abrasion

with the CS-10 or CS-17 Calibrase wheels to produce a test

of sufficient duration to judge correctly the degree of

abrasion resistance.

Figure 75

Leather (Shoe Soles)

Specimen: 100 mm (4 inch) diameter or square

with 6.35 mm

(0.25 inch) center hole.

Wheels and Load

: H-18 or H-22 Calibrade with

500 gram or 1000 gram load.

Evaluation

: Weight loss method; or depth of

wear method [maximum depth of penetration

recommended is 0.8 mm

(0.0312 inch)].

Linoleum

Specimen: 100 mm (4 inch) diameter or square

with 6.35 mm

(0.25 inch) center hole.

Wheels and Load

: H-18 or H-22 Calibrade with

500 or 1000 gram load. For solid linoleum

subjected to extreme wear or cutting action, S-

35 Tungsten Carbide wheels with 1000 gram

load.

Evaluation

: Weight loss method or depth of wear

method [maximum depth of penetration

recommended is 0.8 mm

(0.0312 inch)].

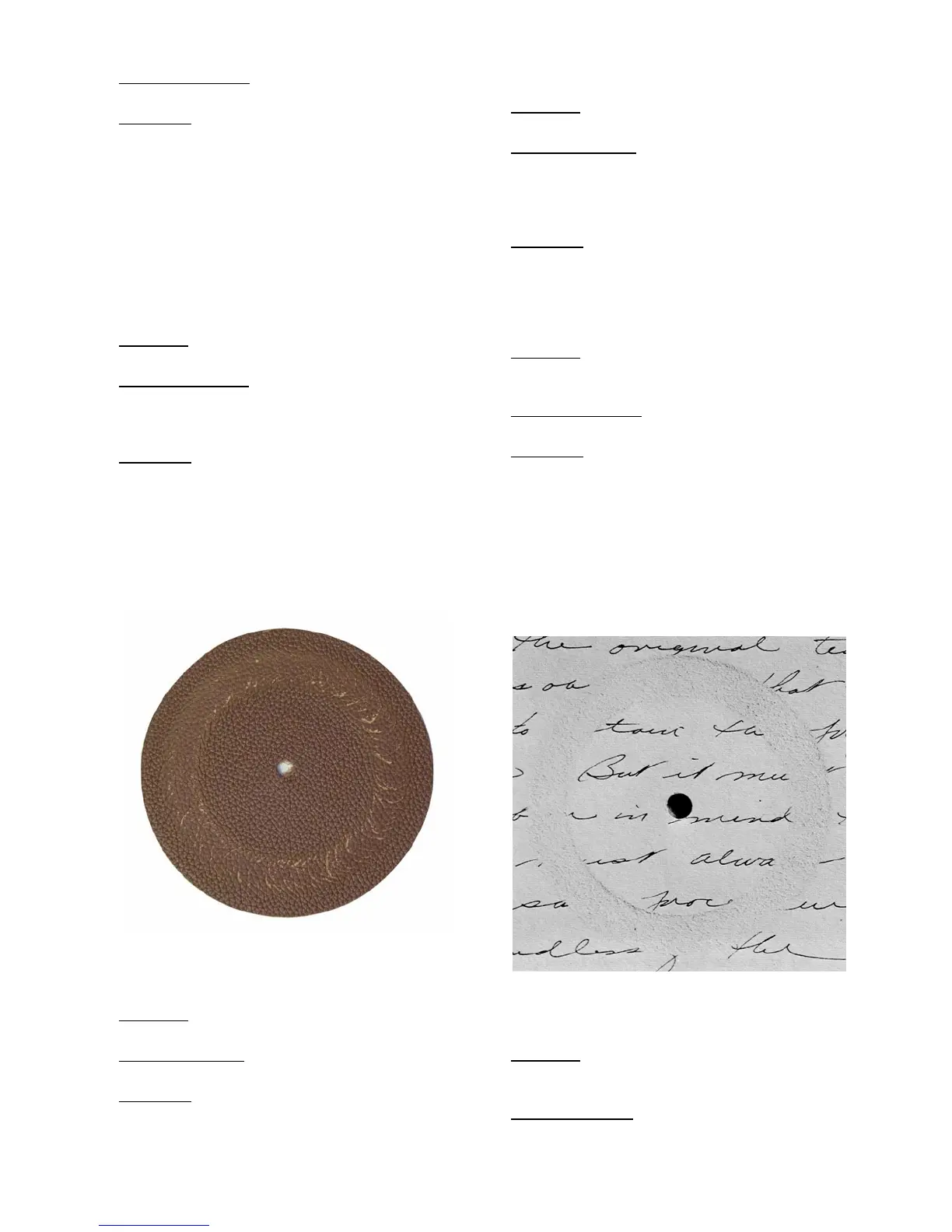

Paper – Erasure Tests (Figure 76)

Specimen: 108 mm (4.25 inch) diameter with 6.35

mm

(0.25 inch) center hole, mounted on S-36 or

S-36-1 Mounting Card.

Wheels and Load

: CS-10 Calibrase with 250

gram or 500 gram load.

Evaluation

: Visual end point determined by

partial erasure of ink marks from wear path

surface.

Remark: The properties to be determined are: 1) ease of

erasure, 2) amount of damage to surface from abrasion, 3)

ability of specimen to accept rewriting after erasure, 4)

number of times the specimen will accept erasure and

rewriting. The specimen is prepared by writing or drawing

circular lines on the surface to be tested using a permanent

ink. The ink should be thoroughly dried on the conditioned

paper before testing.

Figure 76

Paper – Scuffing Test

Specimen: 108 mm (4.25 inch) diameter or square

with 6.35 mm

(0.25 inch) center hole center hole

mounted on S-36 or S-36-1 Mounting Card.

Wheels and Load

: H-10, H-18 or H-22 Calibrade

with 500 or 1000 gram load. Alternately, CS-5

36 5135 / 5155 Operating Instructions ver 1.1

Loading...

Loading...