The Best Way

To Go

About Your

Business

TAYLOR-DUNN

®

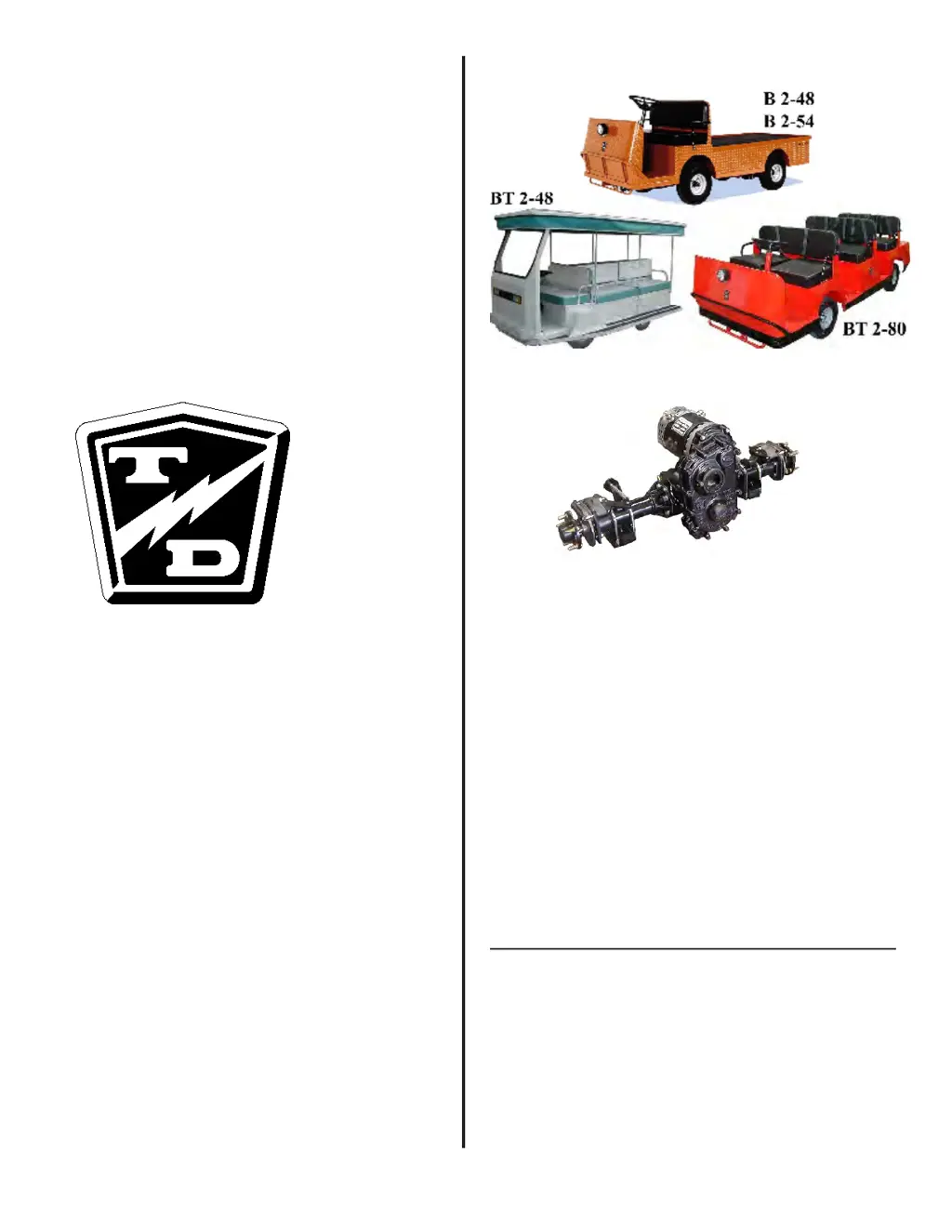

B 2-48/B 2-54 Serial number Starting: 146189

BT 2-48 Serial number Starting: 150719

BT 2-80 Serial number Starting: 159916

All models - Serial Number Ending 177126

MANUAL MB-248-10

Operation, Troubleshooting and

Replacement Parts Manual

Revision: L, 6/28/2017

EQUIPPED WITH GT-DRIVE SYSTEM

GT Drive

Models Inlcuded:

B0-248-36 (B 2-48, 36-volt)

B0-248-48 (B 2-48, 48-volt)

B0-254-36 (B 2-54. 36-volt)

B0-254-48 (B 2-54, 48-volt)

BT-248-36 (36-volt Back to Back Tram)

BT-248-48 (48-volt Back to Back Tram)

BT-280-36 (36-volt 10-passenger Tram)

BT-280-48 (48-volt 10-passenger Tram)

Shown with optional equipment installed