9

Models 150, 152, 162, 168

Introduction

Installation Instructions

Air Cooled Units

Air cooled units require a minimum of 6” (15.2 cm) of

clearanceonallsides of the freezer . Failure to allow for

adequate clearance can reduce the refrigeration

capacity of the freezer and possibly cause damage to

the compressor.

Water Cooled Units

An adequate cold water supply with a hand shut-off

should be provided.

Step 1

Flush all water lines.

Step 2

Connect the water supply line to the inlet (water in)

connection.

Note: If local codes permit, use flexible water lines.

Step 3

Install the drain line into an open trap drain so that the

water flow can be observed.

IMPORT ANT: Do not install a shut-off valve on the

drain line.

Note: Drain water should be warm during normal

operation.

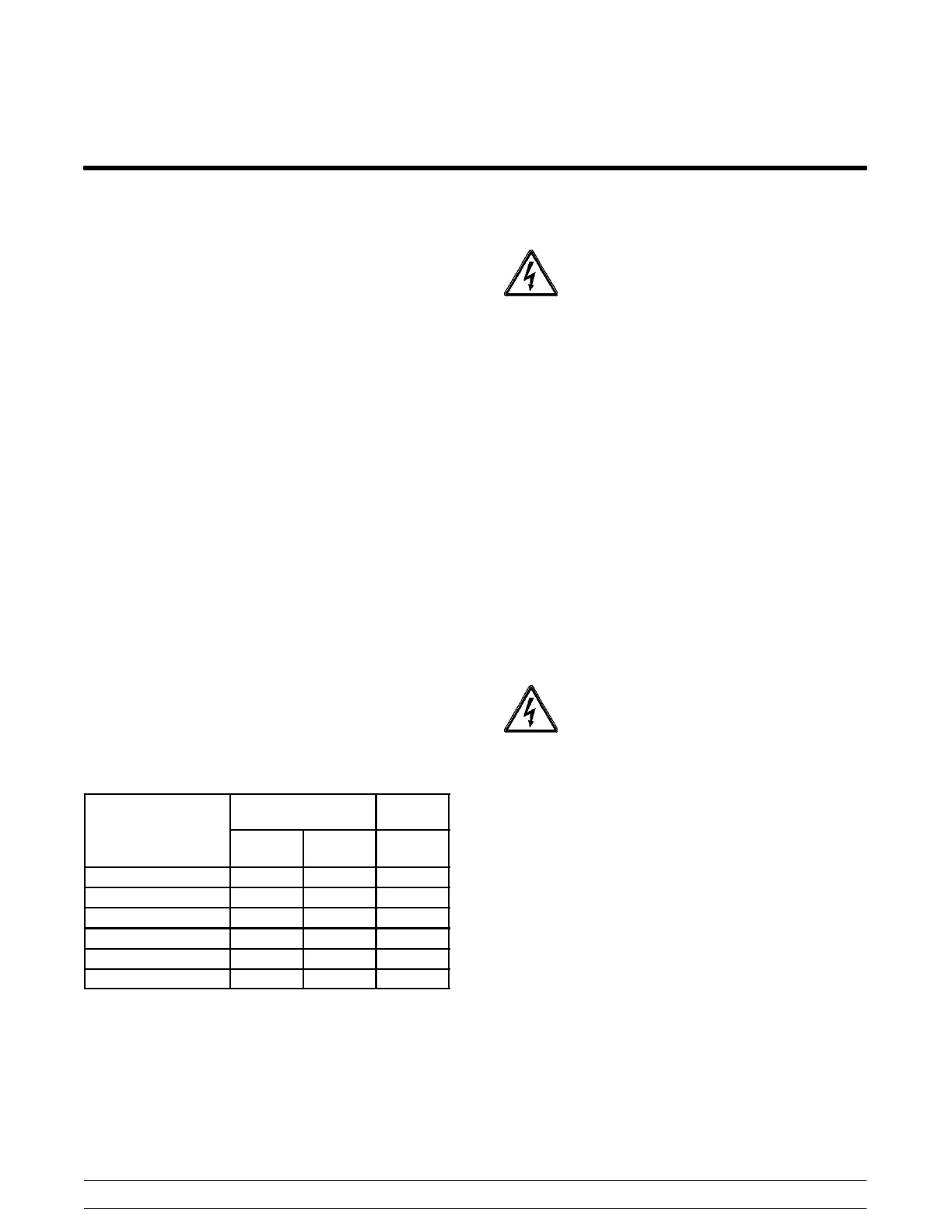

Refrigeratio n

R502

404A /

HP62

o

e

Air

Cooled

Water

Cooled

Air

Cooled

150 Temp. Control 40

150 TQC 34 18

152 Temp. Control 40

152 TQC 34

162 TQC 34 23 18

168 TQC 34 20 18

Separate Hopper Refrigeration

Single Hopper: R12 = 7 oz., 134A = 4.5 oz.

Double Hopper: R12 = 8 oz., 134A = 4.5 oz.

Note: Refrigerant charges are subject to change.

Always refer to the freezer data plate.

Beater Rotation

TURN THE POWER SWITCH OFF! Failure

to follow this instruction may result in electrocution.

Step 1

Remove the door assembly and the beater. Press the

push button switch on the underside of the control

channel. This switch is a latching relay system and will

only drop out if thepower is disconnected, or if abeater

motor overload occurs.

Step 2

Place the power switch in the “W ASH” position. This

activates the beater motor only.

Step 3

Look into the freezing cylinder. The female hex drive

coupling should be turning clockwise.

Step 4

If rotation is not correct, follow the directions on the

beater motor to reverse the rotation.

REMEMBER TO DISCONNECT ALL

POWER TO THE FREEZER! Failure to follow this

instruction may result in electrocution.

Electrical Connections

Each freezer requires one dedicated power supply.

Check the data label on the freezer for fuse, circuit

ampacity and electrical specifications. Refer to the

wiring diagram, provided inside the control box, for

proper power connections.

This equipment is intended to be installed in

accordance with the National Electric Code (NEC),

NFPA 70. The purpose of this code is the practical

safeguarding of persons and property from hazards

arising from the use of electricity. This code contains

provisions considered necessary for safety.

Compliance therewith and proper maintenance will

result in an installation essentially free from hazard.

Loading...

Loading...