8

Introduction

Models 150, 152, 162, 168

Running Specifications

The following are the pressure and temperature

settings recommended by the Taylor Company and

apply to all models covered in this manual.

Expansion Valve

Pressure setting: 502 = 18 to 20 PSI

(124 to 138 kPa).

HP62 & HP 81 = 20 to 22 PSI

(138 to152 kPa)

Normal product temperature should range between

18_Fto20_F (-7.8_Cto-6.7_C).

Mix hopper and standby temperature should range

between 38_Fto40_F(3.3_Cto4.4_C).

High Side

Head pressure on air cooled unitsvaries dependingon

ambient temperatures.

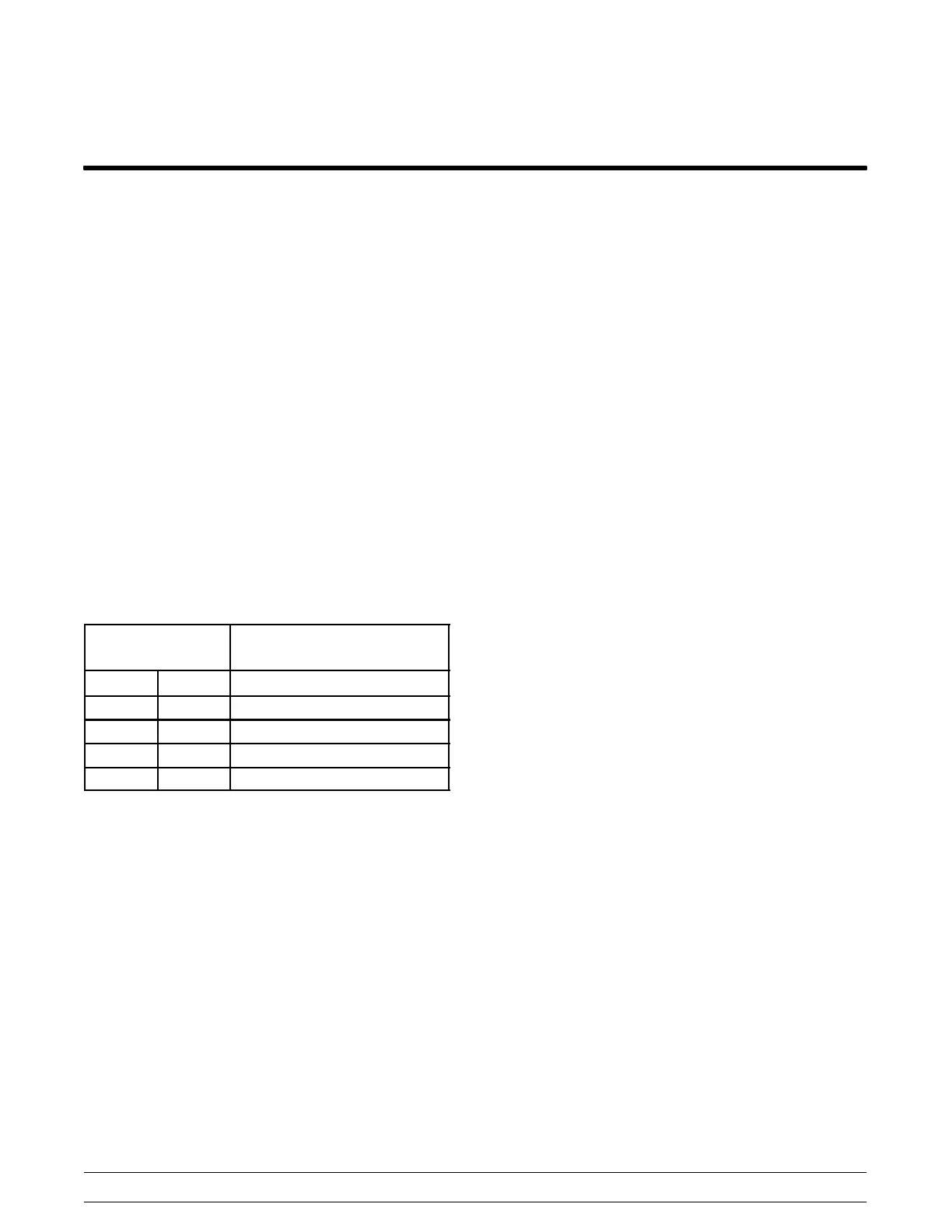

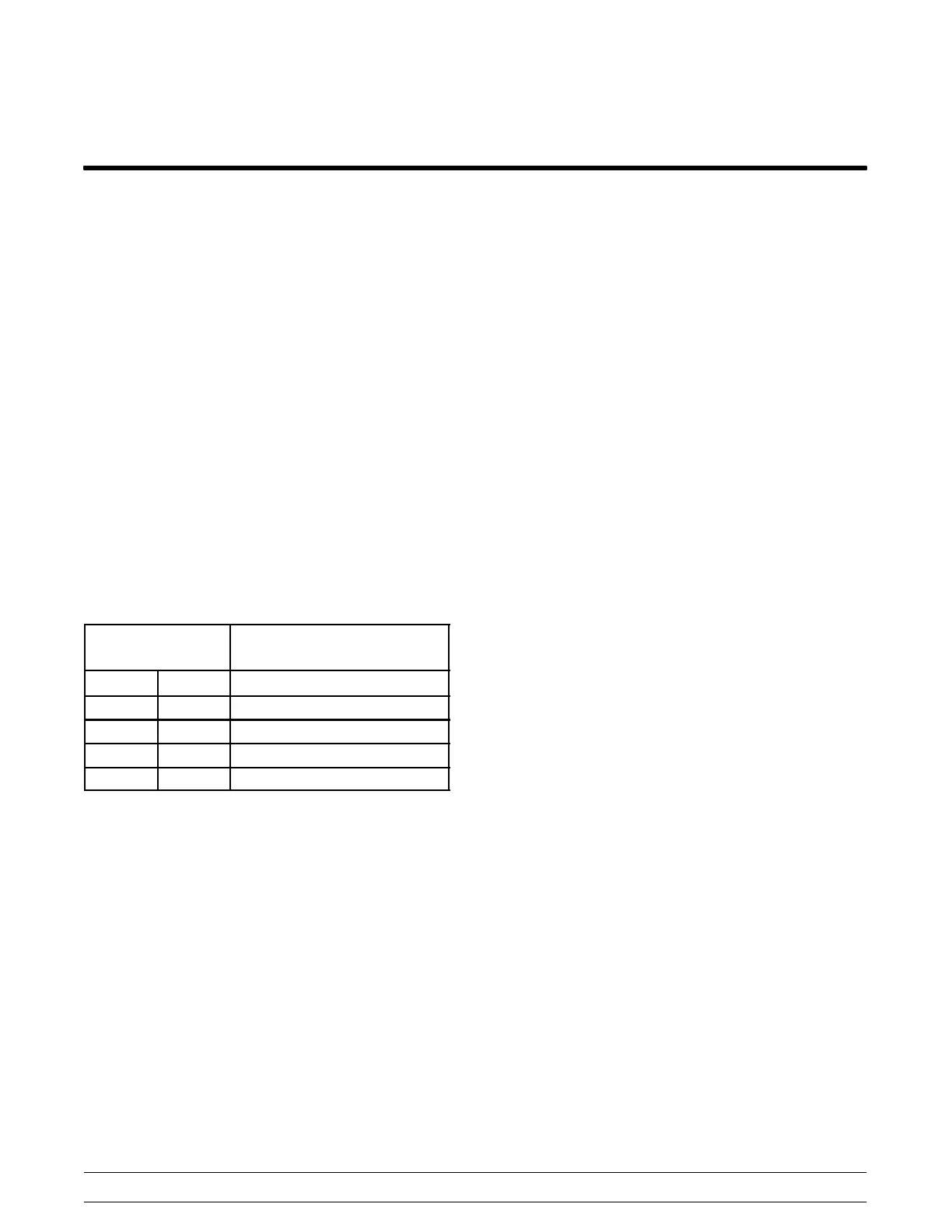

Air Cooled: The following chart indicates normal

operating head pressures at various ambient

temperatures.

Ambient

Temperature

Normal Operating

Head Pressures

F. C. PSI

70_ 21.1_ 240 - 270 (1,655 - 1,862 kPa)

80_ 26.7_ 270 - 300 (1,862 - 2,069 kPa)

90_ 32.2_ 300 - 340 (2,069 - 2,344 kPa)

100_ 37.8_ 340 - 380 (2,344 - 2,620 kPa)

Note: This chart applies to units using R502 or 404A

refrigerant.

Low Side

Low side pressure is determined by the expansion

valve setting. Adjust the pressure higher or lower by

turning the adjustment knob on the expansion valve.

Clockwise adjustments will raise the pressure, and

counterclockwise adjustments will lower the pressure.

Note: Make expansion valve adjustments with mix in

the freezing cylinder and with the machine in the

“AUTO” mode. Allow adequate time for pressure to

stabilize.

Loading...

Loading...