IM-995

Installation, Operation & Maintenance Manual

16

Maintenance (refer to safety section)

observations of sound and vibration will help prolong the life of the fan. If changes are noted check bolt tightness, foundation integrity,

cleanliness of the impeller and or motor, bearing lubrication and drive components. Always keep records of the maintenance that is

performed.

Drive Maintenance (refer to safety section)

V-belt drives need periodic inspection, retensioning and occasional belt

replacement. When inspecting drives, look for dirt buildup, burrs or obstructions

that can cause premature belt or drive replacement. If burrs are found, use fine

emery cloth or a stone to remove them. Be careful that dust does not enter the

bearings.

Check sheaves for wear. Excessive slippage of belts on sheaves can cause wear and vibration. Replace worn sheaves with new ones.

Carefully align sheaves to avoid premature sheave failure. If fraying or other wear is observed to be mostly on one side of the belts,

When replacing belts, replace the entire set. Never use belt dressing on any belts, as it may cause belt wear.

Motor Maintenance

The three basic rules of motor maintenance are:

1. Keep the motor clean.

2. Keep the motor dry.

3. Keep the motor properly lubricated.

motor from overheating.

Some smaller motors are lubricated for life. Lubrication requirements are normally attached to the motor. Use the motor manufacturer’s

recommendations for relubrication. Often motor lubricants are not the same as the fan bearings. If this information is not available,

inspection for wear and shaft corrosion is recommended. Replace the ring if it is making minimal contact with the shaft. If corrosion

is present, treat the shaft with colloidal silver per the ring manufacturer's instructions.

WARNING

When working around belts and pulleys, keep

hands away from pinch points.

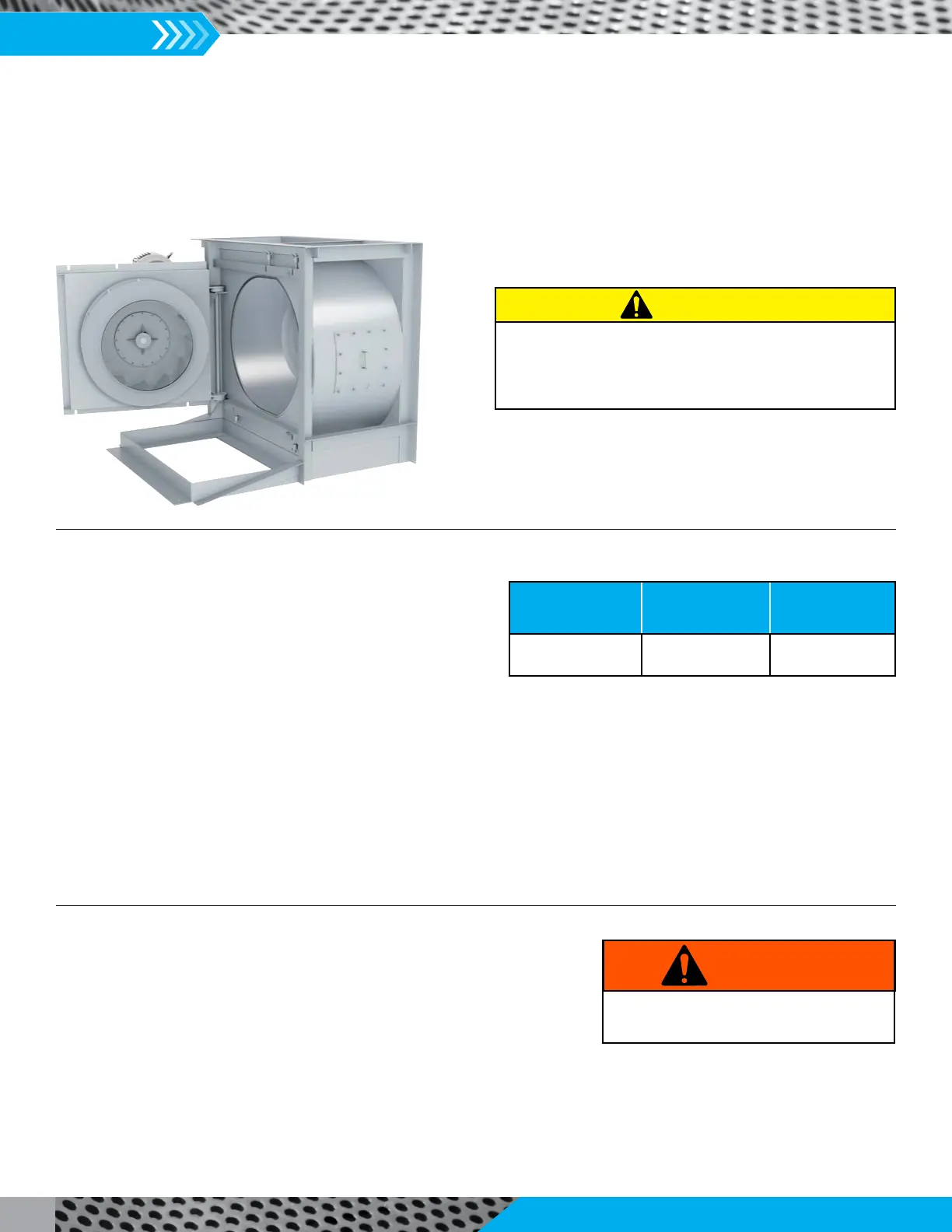

1. Swingout fans should be opened for impeller cleaning and

inspection only and should be closed immediately after

cleaning. Isolate from the electrical supply before opening.

2. Do not run swingout fans the fan in the open position.

CAUTION

Motors Less than 10HP

Running 8 Hrs/Day

(clean environments)

Motors Between

15-40HP

(clean environments)

Motors Running 24/7

or if in dirty/dusty

environments

Lube every 5 years Lube every 3 years

interval by 4

Motor Lubrication Schedule

Do not over lubricate.

Loading...

Loading...