30

Section IV – Pipeline Under Pressure

2.0 Continued J. Check the O-ring on the PIG-SIG V for any

damage. Replace if necessary.

K. Ensure the O-ring is not twisted. Lubricate the O-

ring with silicone grease and the threads wit

h

P

TFE grease (anti-seize) (Figure 4.11).

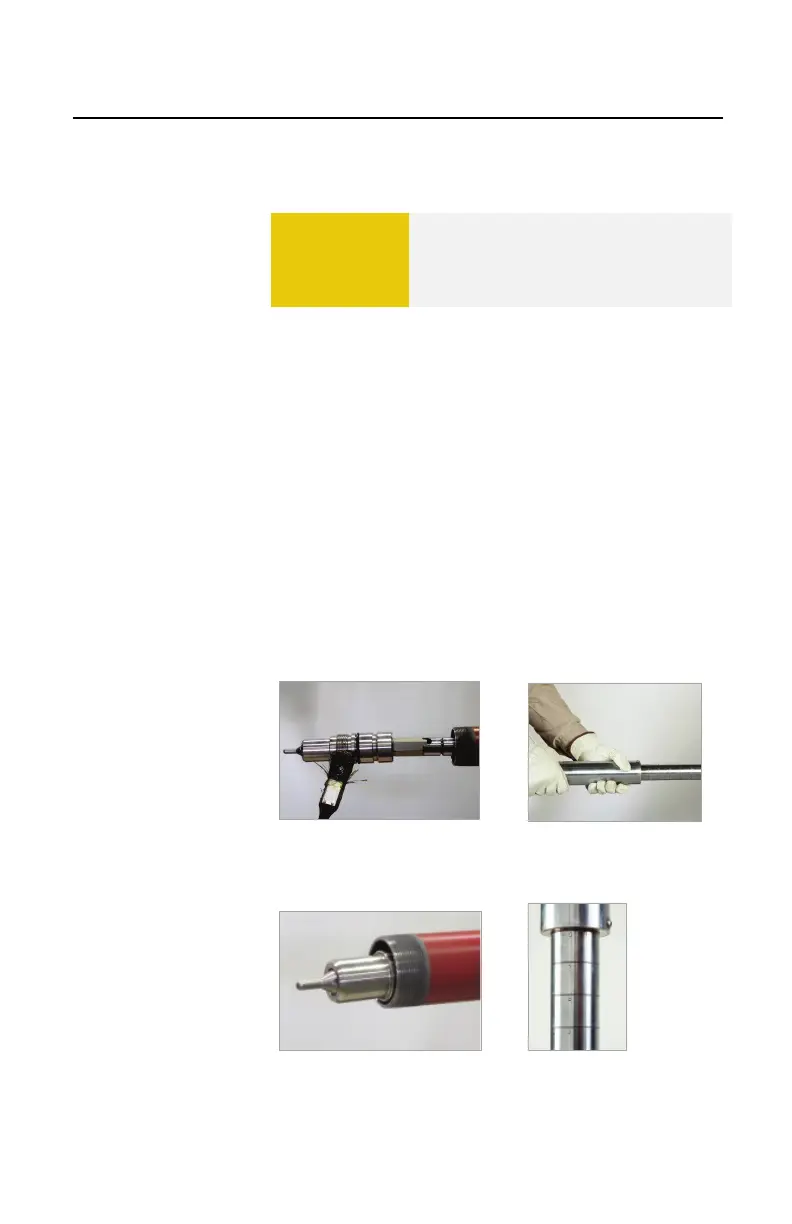

L. While holding the body tube, slowly rotate th

e

f

eed tube counterclockwise (Figure 4.12) until t

he

l

ast thread of the PIG-SIG V is flush with the

bottom of the threaded adapter (Figure 4.13).

M. Using a marker pen, place a mark on the body

tube at the base of the feed tube.

N. Slowly rotate the feed tube counterclockwis

e

(

Figure 4.14) until the feed tube is at zero. Wit

h

t

he PIG-SIG V fully retracted, ensure that th

e

t

rigger does not extend past the end of the drilli

ng

m

achine adapter threads.

Figure 4.11. Lubricate Threads

Tube

Figure 4.13. PIG-SIG V Flush with

Bottom of Thread Adapter

Figure 4.14. Feed Tube at

Zero

CAUTION

A damaged O-ring can create a

hazardous environment from leaking

fluids and result in personal injury

Loading...

Loading...