28

Tester for Automotive Alternators BT030 Manual

EN

3. Start the car engine and reset the load. Wait until the

engine operates steadily at idle.

WARNING! Testing of the alternator in a car should

be performed on promises equipped with combined

extract and input ventilation or fume otake system.

Alternatively, all the measurements should be carried

out outdoor.

WARNING! It is prohibited to exit the testing mode

when engine is running. Otherwise it will result in a

sharp surge of voltage generated by the alternator.

WARNING! In case of spontaneous disconnection

of the black ("B-", battery negative terminal) and/ or

red ("B+, battery positive terminal) clamp it is strictly

prohibited to connect it again when the engine is

running.

4. Use "-V" and "+V" buttons to change the alternator volta-

ge in the range between 13.2V and 14.8V. The measured

voltage (displayed is green) should change in proportion to

a possible deviation by ±0,2V.

5. Use “-V” and “+V” buttons to set any voltage in the range

between 13.2V and 14.8V on the alternator. Increase the

crankshaft rotation speed up to average rpm. In this case,

the voltage value displayed on the device screen must not

change (possible value uctuations with a tolerance of

±0,2V are the norm).

6. Without reducing the crankshaft speed, increase the

load in the alternator by switching on headlights and other

lighting units. The voltage value displayed on the device

screen must not change (possible voltage reduction is by

0.3V).

7. Shut the engine o.

8. Disconnect the BT030 Tester terminals.

9. Failure of one the operational requirements described

in items 2.1, 4, 5 and 6 of the manual, signs the alternator

malfunction.

6. TESTER MAINTENANCE

The BT030 Tester is designed for a long-therm

operation 24/7. However, to ensure the test bench uptime,

it is necessary to provide regular technical inspection and

below described routine maintenance of the device.

Below are the main points that should be checked during

a daily inspection:

• Environmental conditions for the tester operation (tempe-

rature, humidity, air pollution, vibration, etc.).

• Condition of the wires that should be connected to the

device outputs (visual inspection).

• Do not store or use the device in places exposed to high

temperature, humidity, danger of explosion or re, strong

magnetic eld. Exposure to dampness may degrade the

product´s performance.

6.1 Tester Software Update

Update BT030 software as follows:

- Download a new version of the software.

*File with the latest software version can always be

found on our website: www.gauss.com.br

- Copy it to the root of 32GB MicroSD drive formatted in

FAT32.

- Switch the tester o and insert the drive into the MicroSD

connector of the device.

- Switch the tester on by connecting the red wire to the

battery plus and the black one to its minus, or connect the

device to 12V DC power supply.

- On launch, the device will automatically detect a new ver-

sion of the software and start the installation.

- Wait until the installation is completed.

WARNING! Do not interrupt the sotware update

process by disconnecting the unit or removing the

MicroSD drive.

- The device will boot up upon nishing the installation.

- Switch the device o.

- Extract the MicroSD.

6.2 Cleaning and Care

Soft tissues or wipe cloths should be used to cle-

an the surface of the device with neutral detergents. The

display should be cleaned with a special ber cloth and a

screen cleaning spray. No abrasives or solvents should be

used to prevent corrosion, failure or damage to the tester.

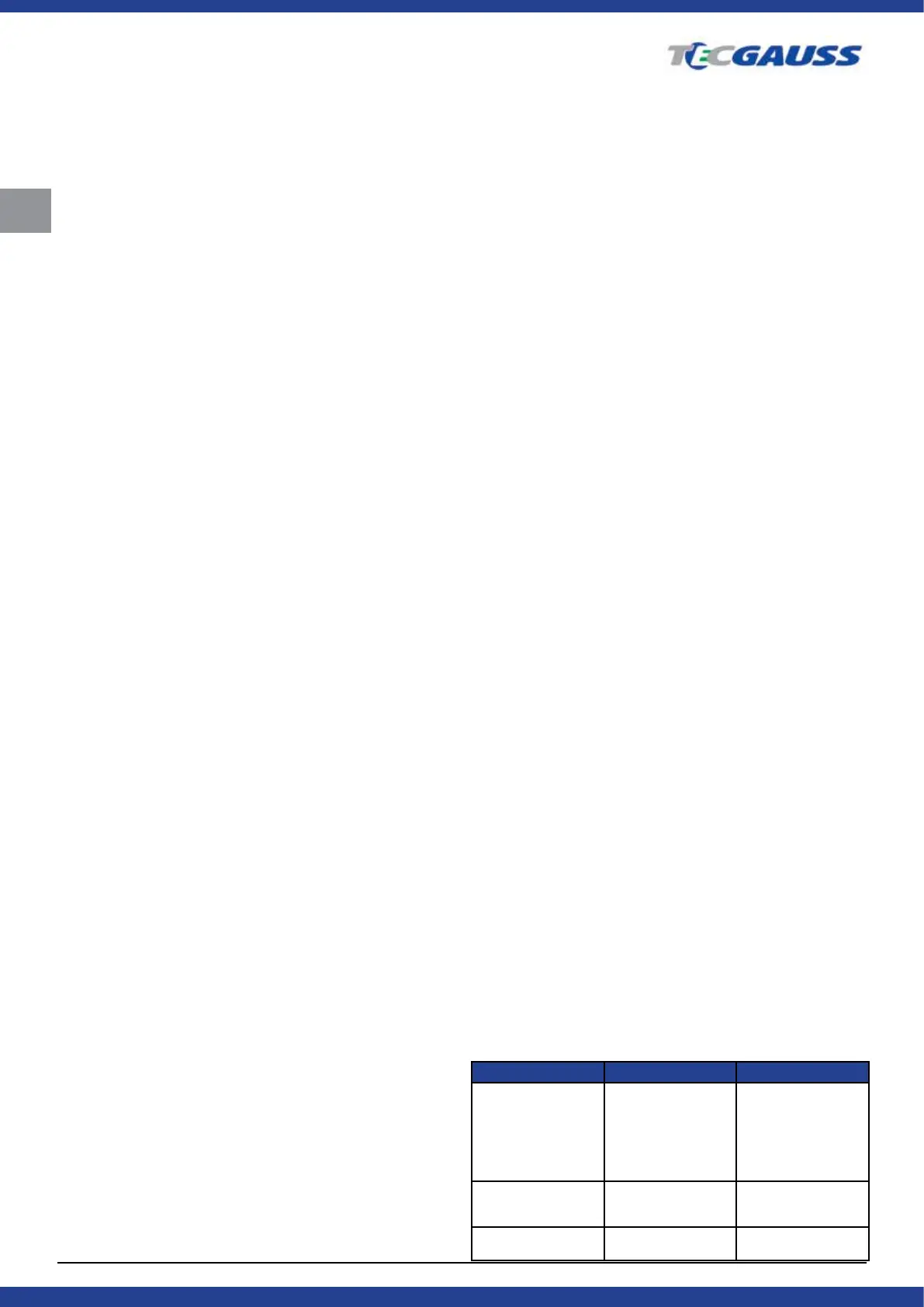

7. MAJOR FAULT AND TROUBLESHOOTING

TECHNIQUES

Possible malfunctions and ways to x them are

described in the below table:

Failure symptom Potential Cause Troubleshooting tips

1. The tester fails to be

switched on or Tested

parameters are dis-

played incorrectly.

1.1 Poor contact with the

dignostic connector.

1.2 Diagnostic cable is

broken.

1.3 Incorrect or poor

connection to the gene-

rator connectors.

1.1 Check the connector

for secure xation.

1.2 Check dagnostic

cable. Replace with new.

1.3 Restore the contact.

2. The display doesn´t

respond to the

operator´s touch.

2.1 The touch screen is

damaged.

2.1 Contact the service

department.

3. Dignostics fails to be

launched.

3.1 Operating system

malfunction.

3.1 Contact the service

department.

Loading...

Loading...