Doc No: OMM50001243

Rev: C Page 20 of 68

This document and all the information contained herei

n are the confidential and exclusive property of TechnipFMC,

and may not be reproduced, disclosed, or made public in

any manner prior to express written authorization by TechnipFMC.

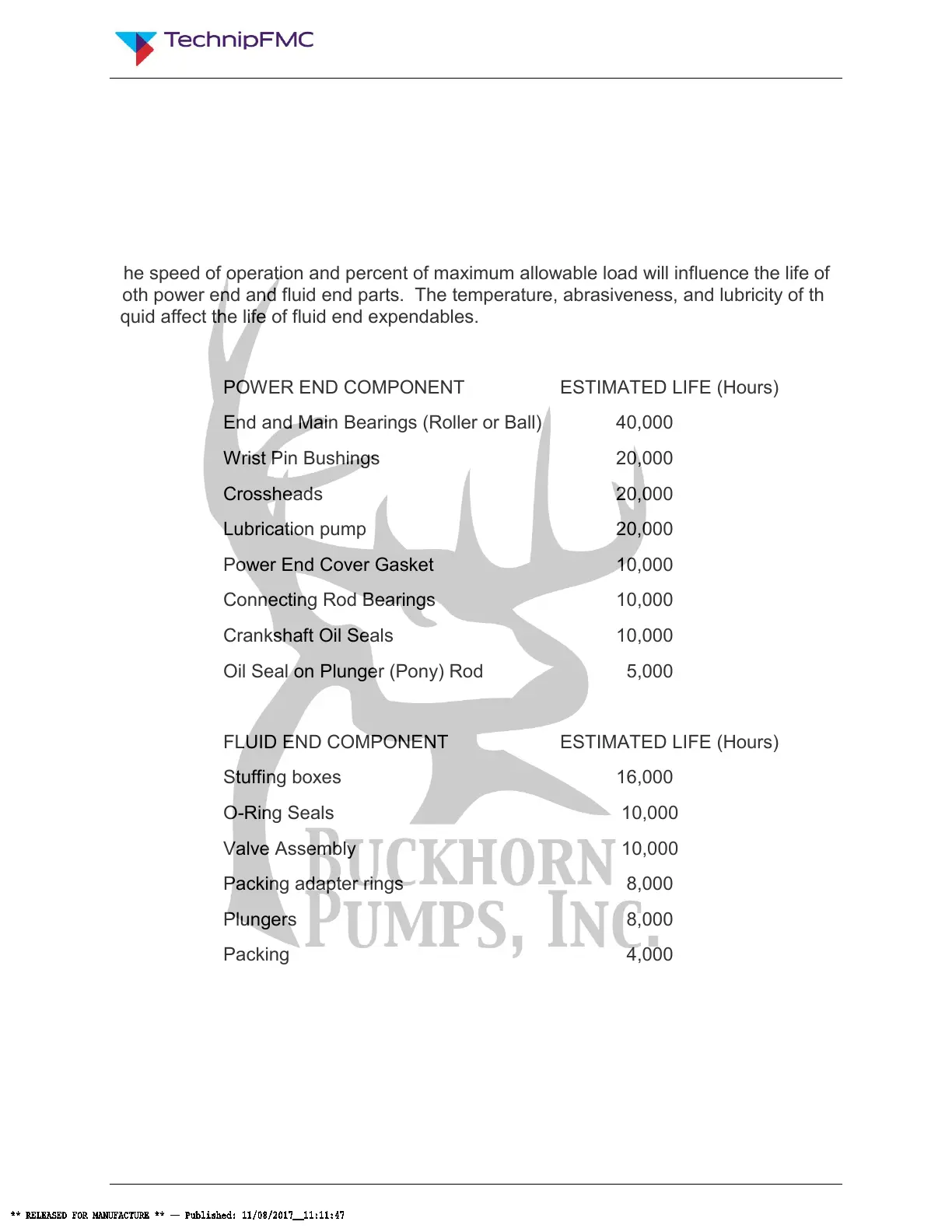

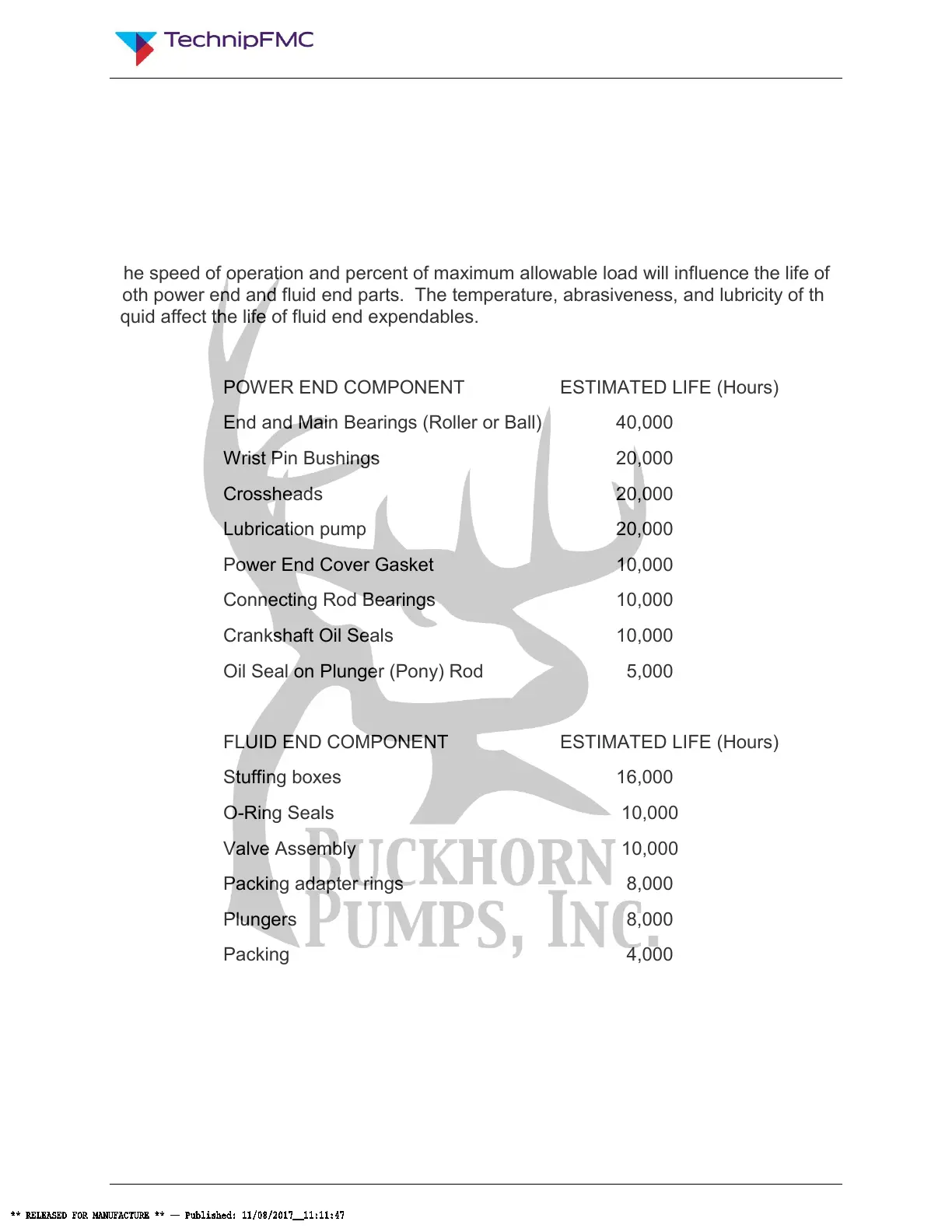

8.0 Estimated Life of Wearing Components

The information given here is an estimate of the average wear life of listed components

in clean liquid service. It is not a guarantee of life for any given application, but is

intended to facilitate maintenance schedules and stocking of spares. The maintenance

of the power end lubrication system will influence the life of the power end components.

The speed of operation and percent of maximum allowable load will influence the life of

both power end and fluid end parts. The temperature, abrasiveness, and lubricity of the

liquid affect the life of fluid end expendables.

POWER END COMPONENT ESTIMATED LIFE (Hours)

End and Main Bearings (Roller or Ball) 40,000

Wrist Pin Bushings 20,000

Crossheads 20,000

Lubrication pump 20,000

Power End Cover Gasket 10,000

Connecting Rod Bearings 10,000

Crankshaft Oil Seals 10,000

Oil Seal on Plunger (Pony) Rod 5,000

FLUID END COMPONENT ESTIMATED LIFE (Hours)

Stuffing boxes 16,000

O-Ring Seals 10,000

Valve Assembly 10,000

Packing adapter rings 8,000

Plungers 8,000

Packing 4,000

Loading...

Loading...