Doc No: OMM50001243

Rev: C Page 61 of 68

This document and all the information contained herei

n are the confidential and exclusive property of TechnipFMC,

and may not be reproduced, disclosed, or made public in

any manner prior to express written authorization by TechnipFMC.

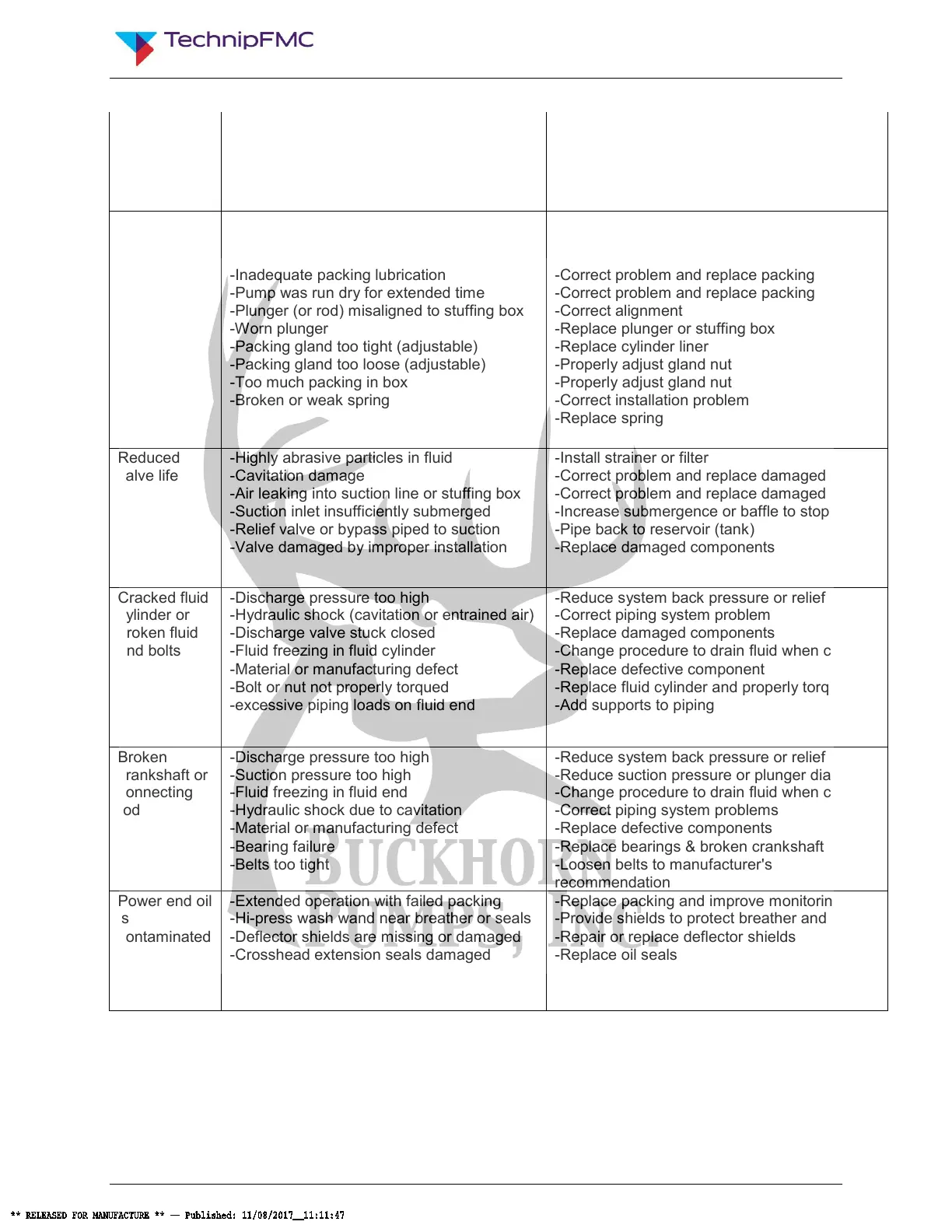

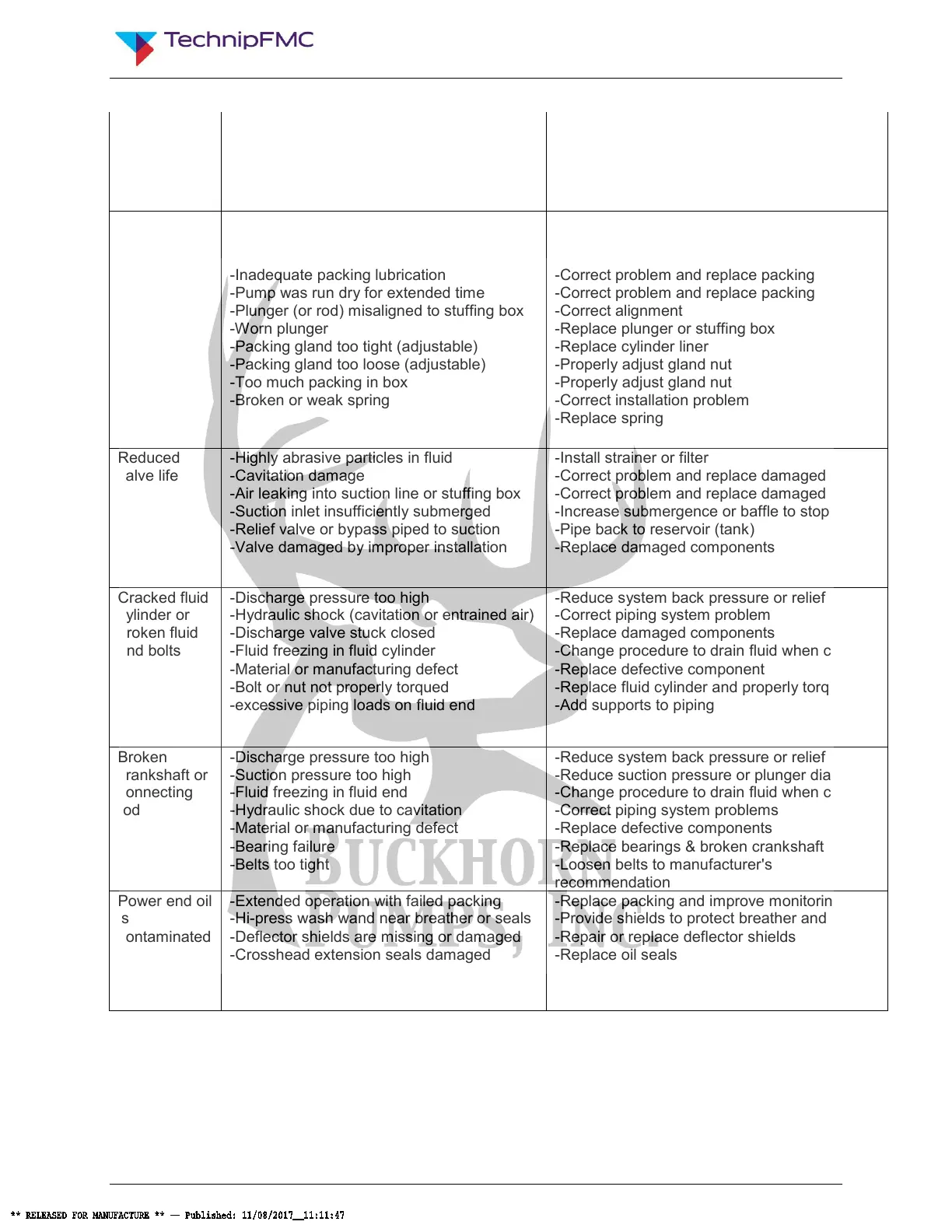

-Fluid cylinder bolts not properly tightened

-Fluid cylinder o-rings (or gaskets) damaged

-Properly tighten and torque bolts

-Replace damaged o-rings or gaskets

Reduced

packing or

piston cup life

-Highly abrasive particles in fluid

-Packing run dry

-Incorrect packing for fluid type

-Inadequate packing lubrication

-Pump was run dry for extended time

-Plunger (or rod) misaligned to stuffing box

-Worn plunger

-Packing gland too tight (adjustable)

-Packing gland too loose (adjustable)

-Too much packing in box

-Broken or weak spring

-Install strainer or filter

-Correct problem & replace packing

-Change to correct packing

-Correct problem and replace packing

-Correct problem and replace packing

-Correct alignment

-Replace plunger or stuffing box

-Replace cylinder liner

-Properly adjust gland nut

-Properly adjust gland nut

-Correct installation problem

-Replace spring

-Highly abrasive particles in fluid

-Cavitation damage

-Air leaking into suction line or stuffing box

-Suction inlet insufficiently submerged

-Relief valve or bypass piped to suction

-Valve damaged by improper installation

-Install strainer or filter

-Correct problem and replace damaged valves

-Correct problem and replace damaged valves

-Increase submergence or baffle to stop vortex

-Pipe back to reservoir (tank)

-Replace damaged components

Cracked fluid

cylinder or

broken fluid

end bolts

-Discharge pressure too high

-Hydraulic shock (cavitation or entrained air)

-Discharge valve stuck closed

-Fluid freezing in fluid cylinder

-Material or manufacturing defect

-Bolt or nut not properly torqued

-excessive piping loads on fluid end

-Reduce system back pressure or relief valve

-Correct piping system problem

-Replace damaged components

-Change procedure to drain fluid when cold

-Replace defective component

-Replace fluid cylinder and properly torque

-Add supports to piping

Broken

crankshaft or

connecting

rod

-Discharge pressure too high

-Suction pressure too high

-Fluid freezing in fluid end

-Hydraulic shock due to cavitation

-Material or manufacturing defect

-Bearing failure

-Belts too tight

-Reduce system back pressure or relief valve

-Reduce suction pressure or plunger diameter

-Change procedure to drain fluid when cold

-Correct piping system problems

-Replace defective components

-Replace bearings & broken crankshaft or rod

-Loosen belts to manufacturer's

recommendation

Power end oil

is

contaminated

-Extended operation with failed packing

-Hi-press wash wand near breather or seals

-Deflector shields are missing or damaged

-Crosshead extension seals damaged

-Replace packing and improve monitoring

-Provide shields to protect breather and seals

-Repair or replace deflector shields

-Replace oil seals

Loading...

Loading...