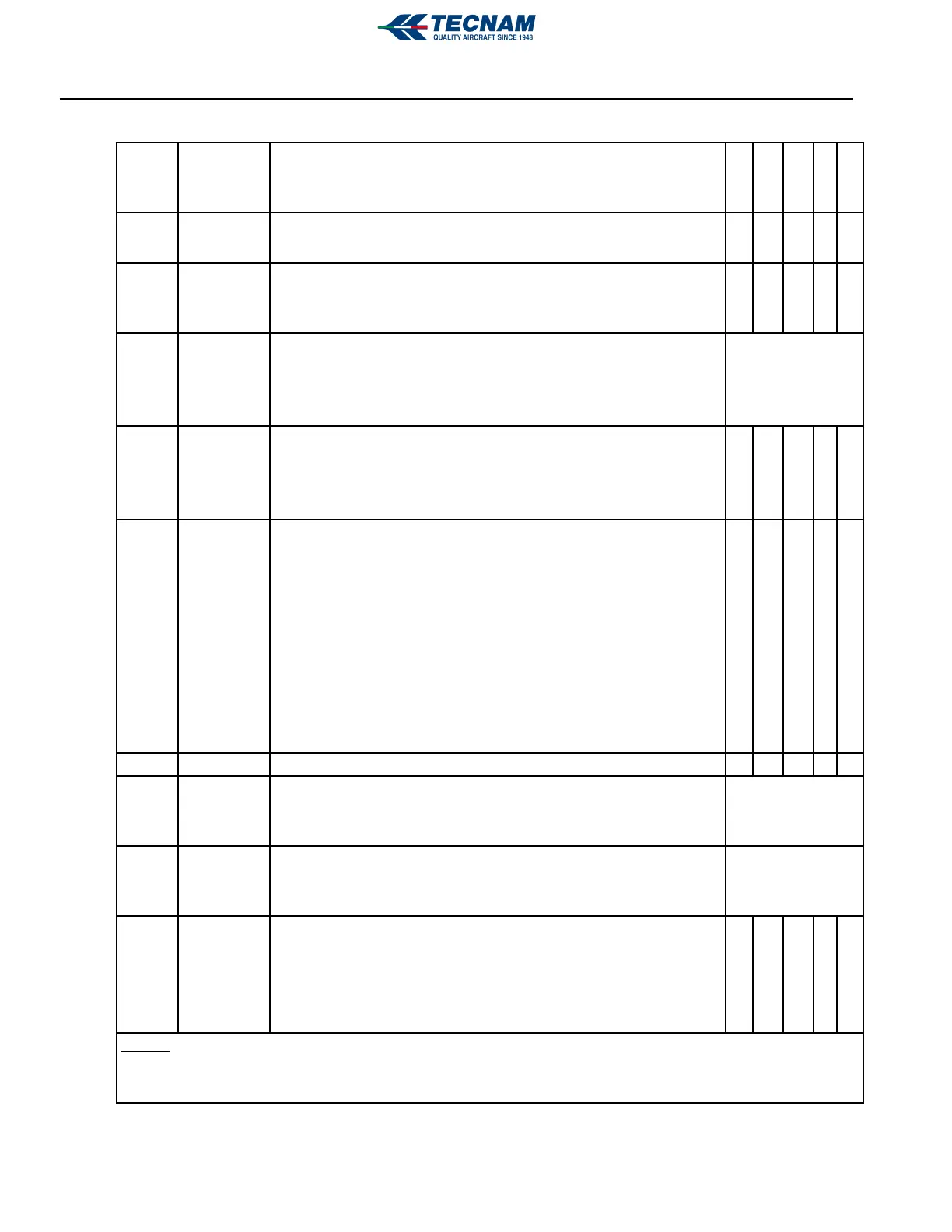

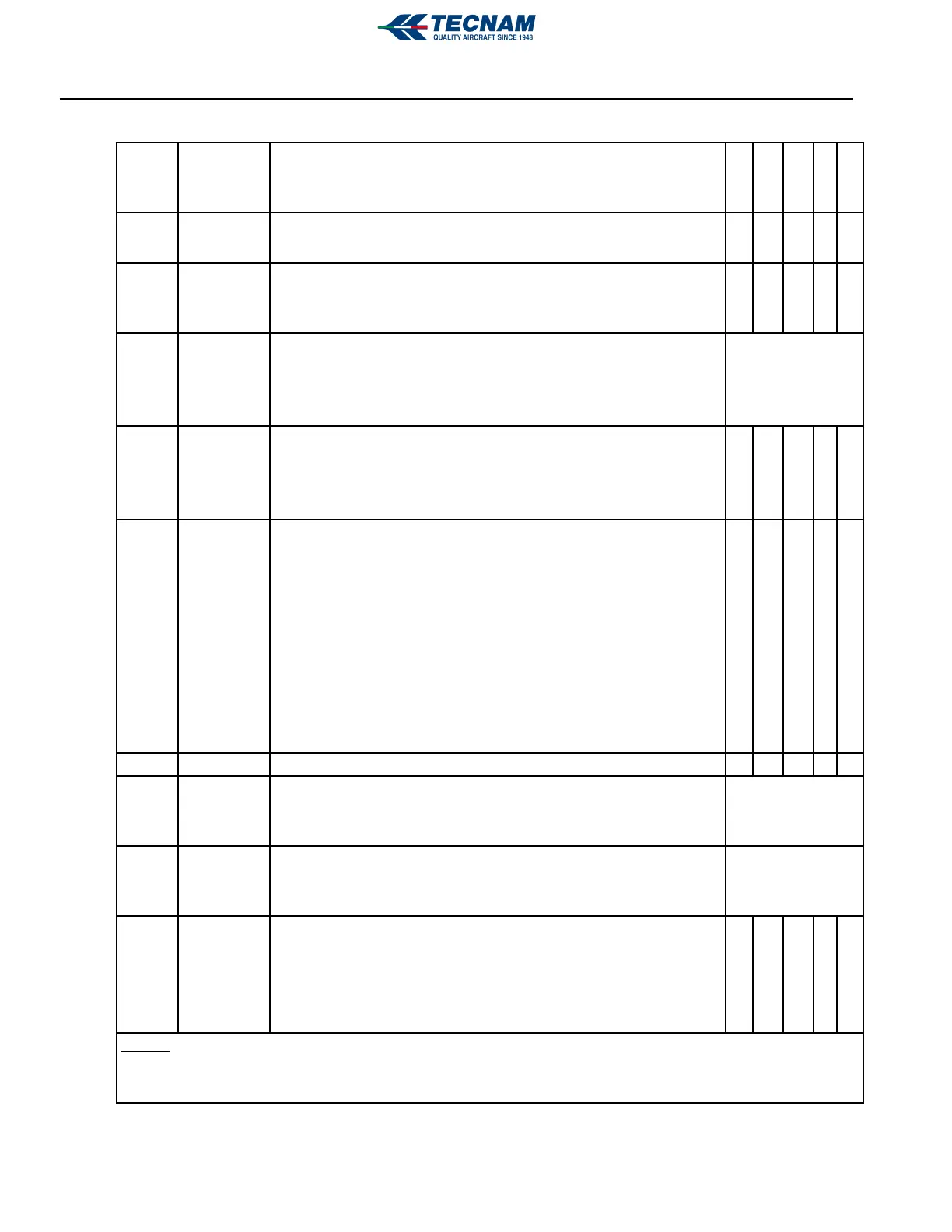

P2012

AIRCRAFT MAINTENANCE MANUAL

corrosion, cracked or buckled tubes and engine mount isolators

attachments. Check engine mount bolts and engine electrical

bonding.

71-00 Powerplant Engine electrical harness and equipment : check for condition

and security of installation

X

(*)

71-00 Powerplant Visually inspect air induction system for integrity. Check the

alternate static air source valve for integrity and correct

operation.

X

71-00 Powerplant Inspect induction system filter according to Brackett Aero Filters

manufacturer manual. Verify expiry date.

Refer to CMM

(see Bracket

Aero Filters Doc

No I-194.)

71-00 Powerplant Check for free movement of power levers. Check engine and

propeller control cables (bowden) full travel and correct

operation. Check for restricted movement, interference or

unusual freeplay. Check friction for operation.

X

71-00 Powerplant Engine compartment: check for fuel, oil liquid leakages; inspect

hoses, fittings, clamps and all other components of the systems

for cracks, holes, dents. bulges and other signs of damage that

might restrict The fluid flow or cause a leakage. All lines must be

inspected to ensure that they are properly supported and are not

rubbing against a structure. Fittings should be checked for signs

of improper installation. Overtorquing, excessive tension, or

other conditions which may lead to a failure. Inspect engine

parameters sensors and fire detector sensor for general

condition and security of installation.

X

71-00 Powerplant Check engine buffies and sealing.

X

71-00 Powerplant Inspect the engine according to Maintenance Manual.

Refer to MM (see

Lycoming MM-

TE0-540-CIA)

71-00 Powerplant Engine Overhaul according to Maintenance Manual.

Refer to MM (see

Lycoming MM-

TE0-540-CIA)

71-30 FireSeals Check engine baffles for correct installation and absence of

chaffing for near items (wiring, pipes, engine mount). Inspect

engine baffles for damage, cracks, dents, kinks. Make sure that

the holes are not ovalized. Check fasteners for tightening, wear

and tear. Inspect silicone rubber for condition and wear.

X

NOTE:

If MOD 2012/057 is installed, Check the westgate drainage fitting for leakage and verify correct

installation and fitting torque. Verify the correct installation of the support and clamps, Refer to ATA 72.

Check support, clamps and fasteners for cracks, damage or deformations.

05-20-00

Page 32

5

th

Edition - Rev. 0

2022, Jan 14

Loading...

Loading...