P2012

AIRCRAFT MAINTENANCE MANUAL

LUBRICATION CHARTS - DESCRIPTION AND OPERATION

LUBRICATION CHARTS

1. General

Proper lubrication procedures allow for A/C service life extension and for reducing the frequency of

repairs.

In addition, periodic application of recommended lubricants, as detailed in the following paragraphs,

and observance of parts cleanliness will insure the maximum efficiency of all moving parts.

Refer to Lubrication Charts and Schedule for lubrication instructions, locations, time intervals. If

necessary, refer to Inspection Caps for access panel identification.

To insure the best results from the application of lubricants, observe the following precautions:

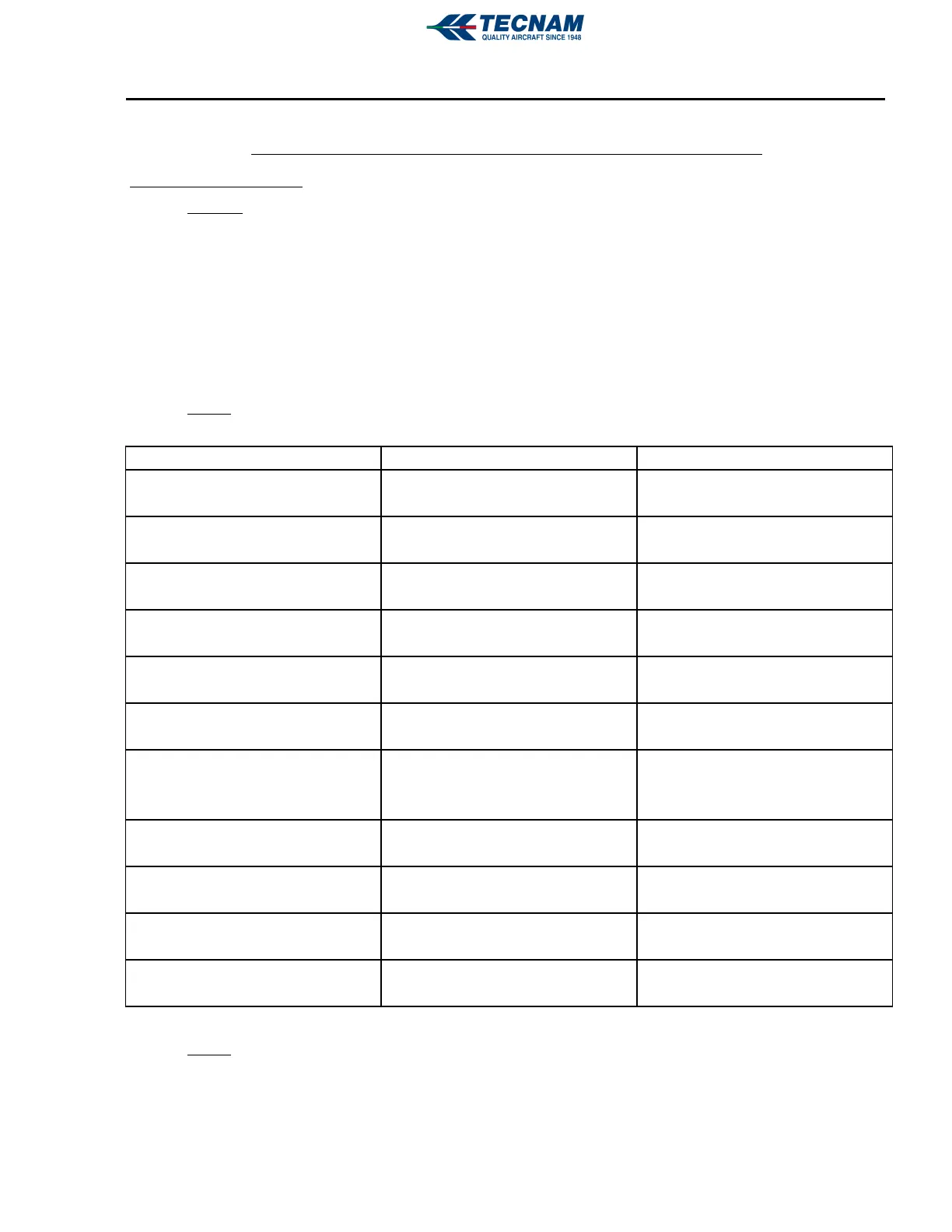

NOTE: Use recommended lubricants (Refer to Table 1).

Table 1 - Approved/Recommended Lubricants

ITEM SPECIFICATION LUBRICANT

1 MIL-G-3278 Grease, generic lubrication (e.g.

ESSO Beacon 325)

2 MIL-G-25013E Grease, bearings lubrication (e.g.

AEROSHELL Grease No. 15)

3 - Universal Airframe Grease

AEROSHELL Grease No. 33

4 - Grease, bearings lubrication

AEROSHELL Grease No. 5

5 MIL-PRF-23827C Multi-purpose aerosol grease (e.g.

ZIP-CHEM D-5907NS Aerosol)

6 - 3M aerosol white grease 8875

Lithium Lube

7 - Cleveland wheel bearing approved

grease: MOBIL Aviation Grease

SHC 100

8 - ACF-50 anti-corrosion lubricant

compound

9 - HHS 2000 wurth spray adhesive

lubricant

10 - BR2- Plus Molykote Grease

(Mineral anticorrosive Grease)

11 MIL-PRF-23827C (Type II) Grease, beraings lubrication (e.g.

AEROSHELL Grease No. 7)

NOTE: Check the components to be lubricated for evidence of excessive wear and if

necessary, replace them.

05-30-00

Page 1

5

th

Edition - Rev. 0

2022, Jan 14

Loading...

Loading...