Maintenance

6–4

TDS 340A, TDS 360 & TDS 380 Technical Reference

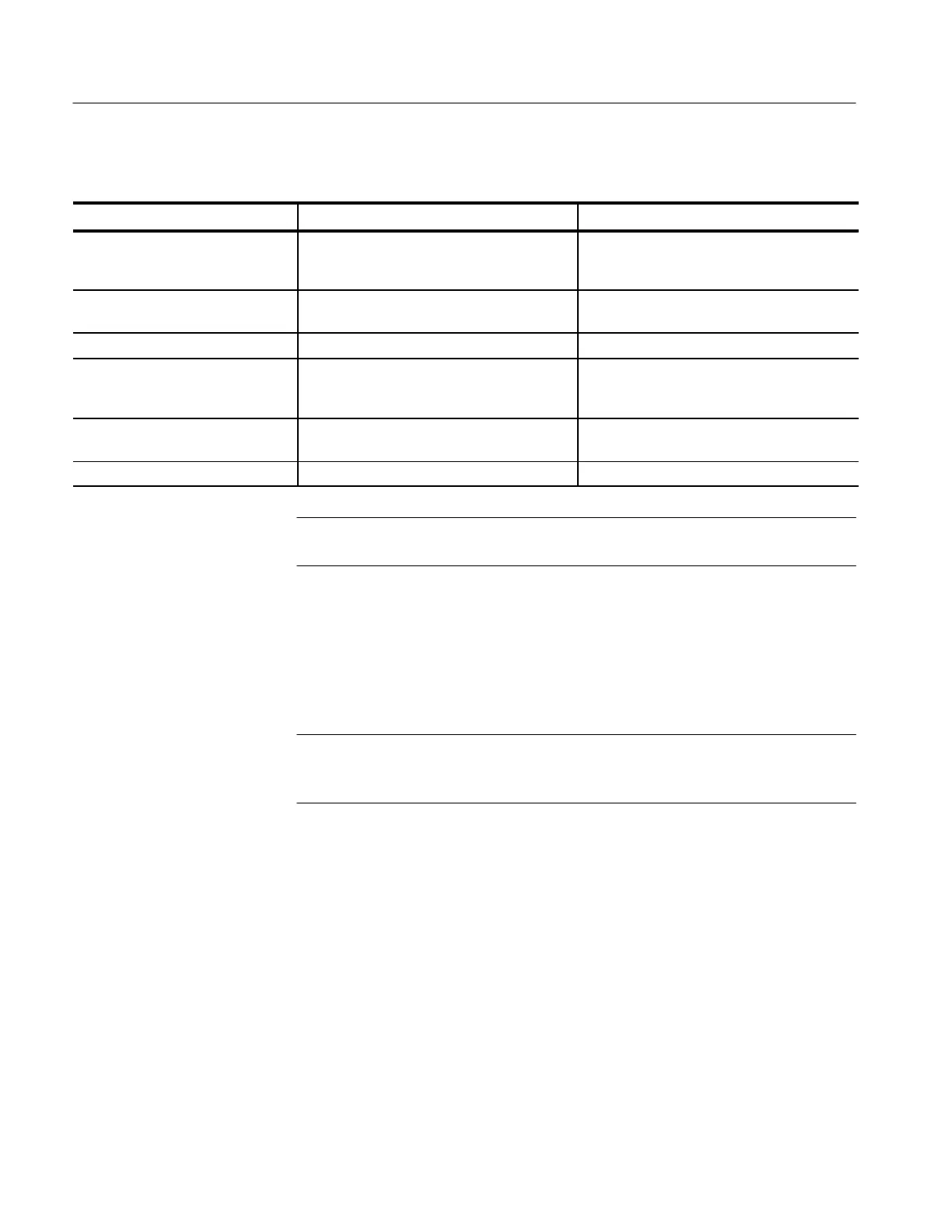

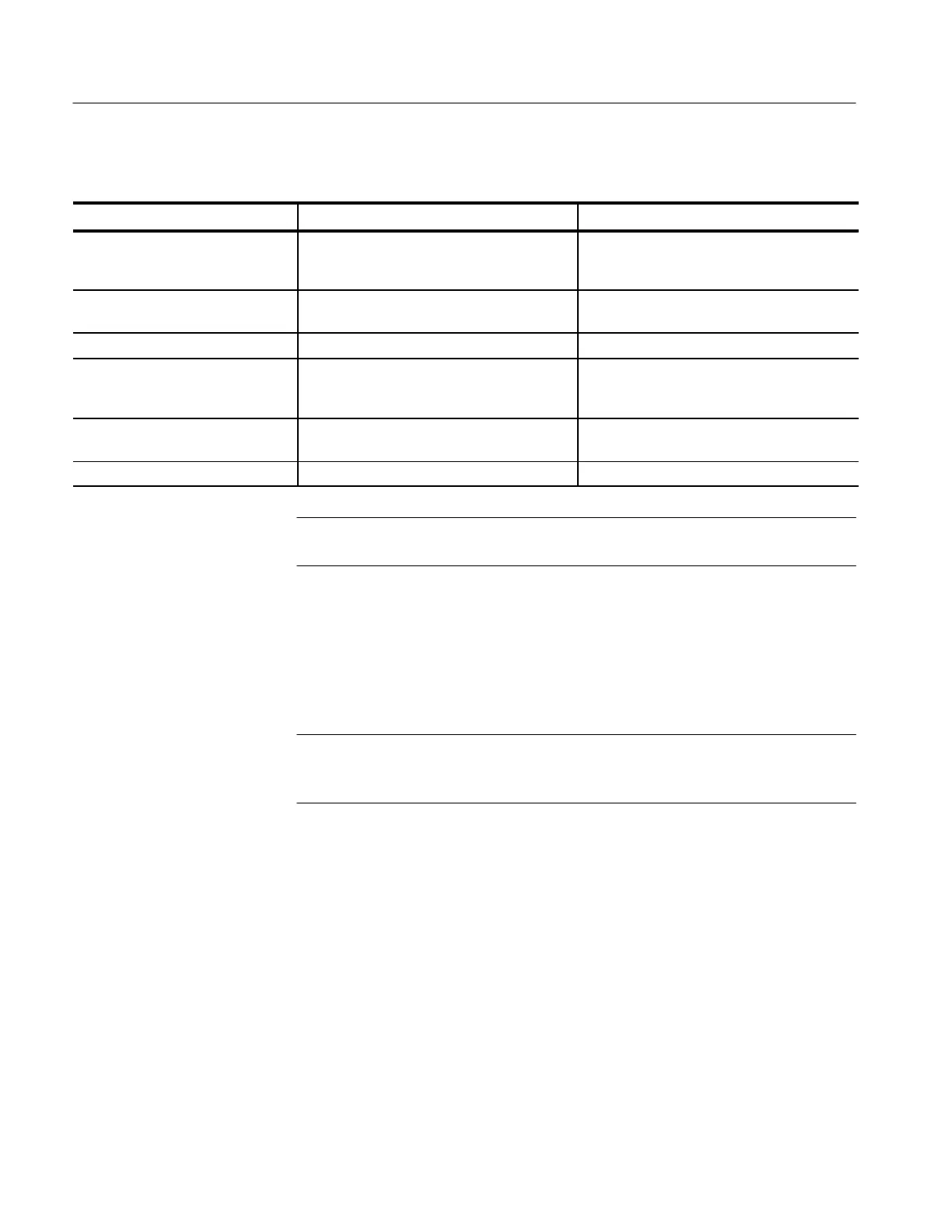

Table 6–2: Internal inspection check list

Item Inspect for Repair action

Circuit boards Loose, broken, or corroded solder connec-

tions. Burned circuit boards. Burned, broken,

or cracked circuit-run plating

Remove the failed module and replace it with

a new module

Resistors Burned, cracked, broken, or blistered condition Remove the module with the faulty resistor

and replace it with a new module

Solder connections Cold solder or rosin joints Resolder joint and clean with isopropyl alcohol

Capacitors Damaged or leaking cases. Corroded solder

on leads or terminals

Remove the module with the faulty capacitor

and replace it with a new module from the

factory

Wiring and cables Loose plugs or connectors. Burned, broken, or

frayed wiring

Firmly seat connectors. Repair or replace

modules with defective wires or cables

Chassis Dents and deformations Straighten, repair, or replace chassis

STOP. If, after doing steps 1 and 2, a module is clean upon inspection, skip the

remaining steps.

1. Blow off dust with dry, low-pressure, deionized air (approximately 9 psi).

2. Remove any remaining dust with a lint free cloth dampened in isopropyl

alcohol (75% solution) and rinse with warm deionized water. (A cotton-

tipped applicator is useful for cleaning in narrow spaces and on circuit

boards.)

NOTE. If steps 1 and 2 do not remove all the dust or dirt, the oscilloscope may be

spray washed using a solution of 75% isopropyl alcohol by doing steps 3

through 7.

3. Gain access to the parts to be cleaned by removing easily accessible shields

and panels (see Removal and Replacement procedures).

4. Spray wash dirty parts with the isopropyl alcohol and wait 60 seconds for the

majority of the alcohol to evaporate.

5. Use hot (120_ F to 140_ F or 48.9_ C to 60_ C) deionized water to

thoroughly rinse them.

6. Dry all parts with low-pressure, deionized air.

7. Dry all components and assemblies in an oven or drying compartment using

low-temperature (125_ F to 150_ F or 51.7_ C to 65.5_ C) circulating air.

Cleaning Procedure —

Interior

Loading...

Loading...