57

GB

Mor n.

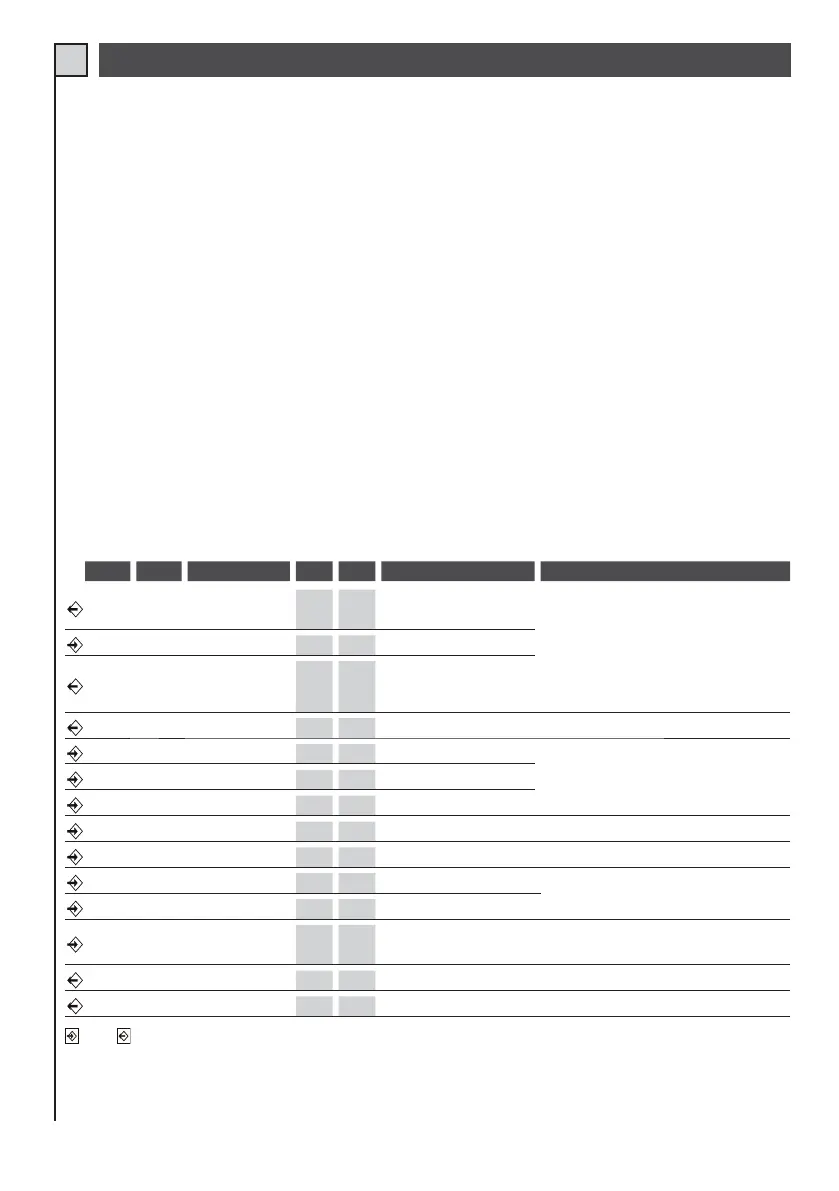

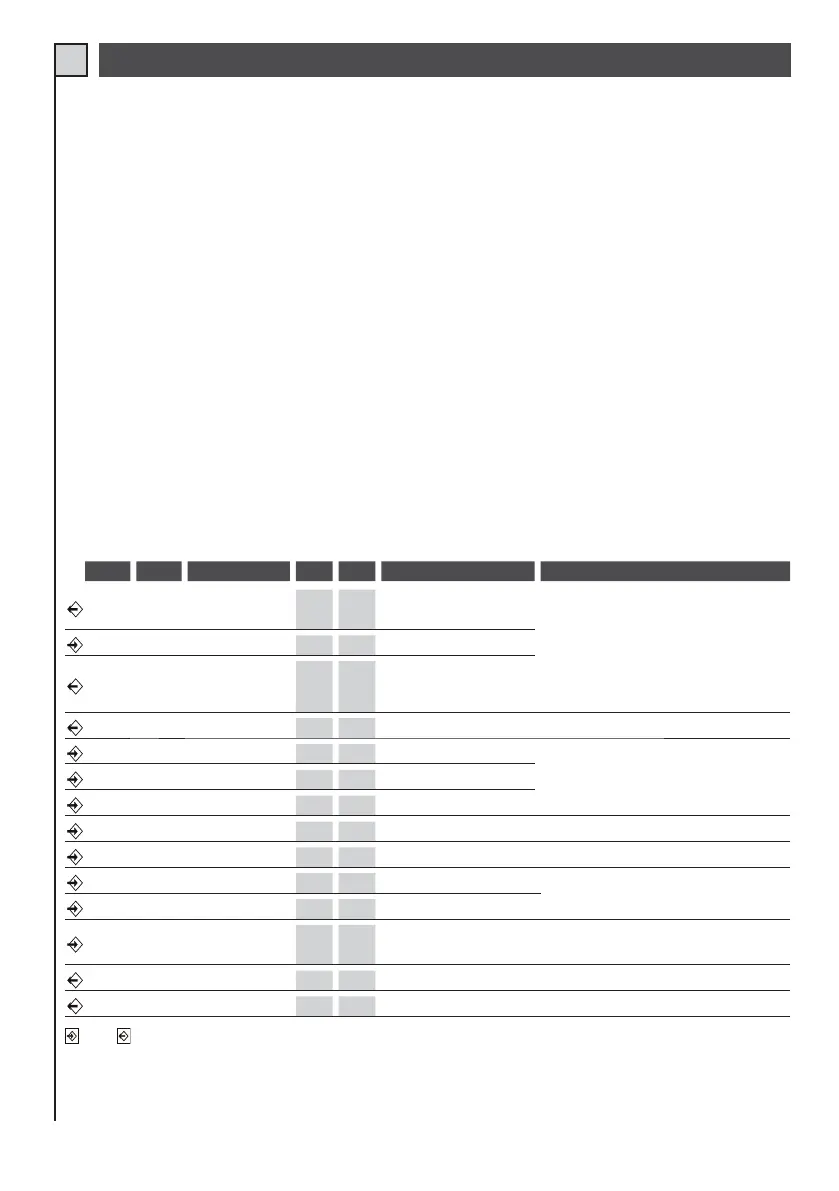

Mor n. Device V I max Function Notes

12

Transformer

(primary)

230V 0,5A

Power supply

Connect this output to the primary of the transformer supplied

35Line

230V 1A

Control unit power supply

Connect to 230Vac line. See electrical connections.

67

Flashing light or

lamp

230V 0,5A

Movement indicator

During the manoeuvres with control unit powered

by battery only, the flashing frequency is reduced.

Lit during manoeuvre. Activation can be set in advance (pre-flashing):

see function dip switch no. 5. Other functions are possible with this output

by combining dip-switches 3 and 4 (see table 3)

89Lamp

12Vcc 1A

Courtesy light

Lit during manoeuvres, and turns off with a delay of approx. 2 minutes.

11 10 , 15 NO/NC Contact Edge on closing (C.M.)

On closing stops the motor and opens completely. See table 2 for

connection types.

12 10 , 15 NC contact. Photocell 1

Inverts travel during closing.

Connect this input to the common if not used.

13 10 , 15 NC contact. Stop

Blocks all functions.

Connect this input to the common if not used.

14 10 , 15 N.O. pushbutton. Step/step

See function dip-switch no.1 and 2 (table 3)

16 17 Auxiliary

24Vcc 1A

Power supply

Permanent for power supply of photocells and external receivers.

18 Rx aerial Sheath

If a receiver is connected to the specific connector, see aerial

specifications as required by the manufacturer.

19 Rx aerial Control unit

20 21

Transformer

(secondary)

22Vca 6,8A

Power supply

Connect this input to the secondary of the transformer supplied (22V).

22 23 CB24

24Vcc 5A

Battery charger (optional)

Provision for connection of battery charger CB24 (optional) and

batteries (optional)

24 25 Motor

24Vcc 5A

Open/close

Input Output

TAB. 1

ELECTRICAL CONNECTIONS

For connections, refer to tables 1 and 2 and figure 15.

In the case of existing systems a general check should be made of the condition of wiring (section, insulation,

contacts) and auxiliary equipment (photocells, receivers, pushbutton panels, key-operated switches etc.).

1) The section of the cables must be calculated on the basis of their length and absorbed current.

2 Do not use a single “multi-pole” type cable in common with other equipment.

3) When very long control cables are used (over 50 metres) decoupling is recommended by means of relays

installed in the vicinity of the control unit.

5) All N.C. contacts associated with the same input must be connected in series.

6) All N.O. contacts associated with the same input must be connected in parallel.

Recommendations for a correct electrical installation:

4) All N.C. inputs. (photocells, safety edges and stop contacts) not used in the control unit must be

shorted with the common.

- For the control unit power supply, the INSERTION OF AN EXTERNAL DISCONNECT SWITCH (not

supplied) is envisaged, which must be independent and sized according to the load.

- The equipment must be installed « PROFESSIONALLY » by personnel with qualifications as

envisaged by current legislation and in compliance with the standards EN 13241-1, EN 12453 and

EN 12445 governing safety of the automation.

Loading...

Loading...