Display

Name&Description

Range

Display

condition

Default

value

Anti-resetwindup

Anti-resetwindup%

ManualReset

/

to

%

to

(for0.1

resolution)

to

(for1 )

to

(foranalog

input)

o

o

ARW=MAnL

Proportional

band>0and

Integraltime

=0.

20

Programming.

Cycletime

Cycletime-user

/

/

to

sec

Cycletime=

USEr

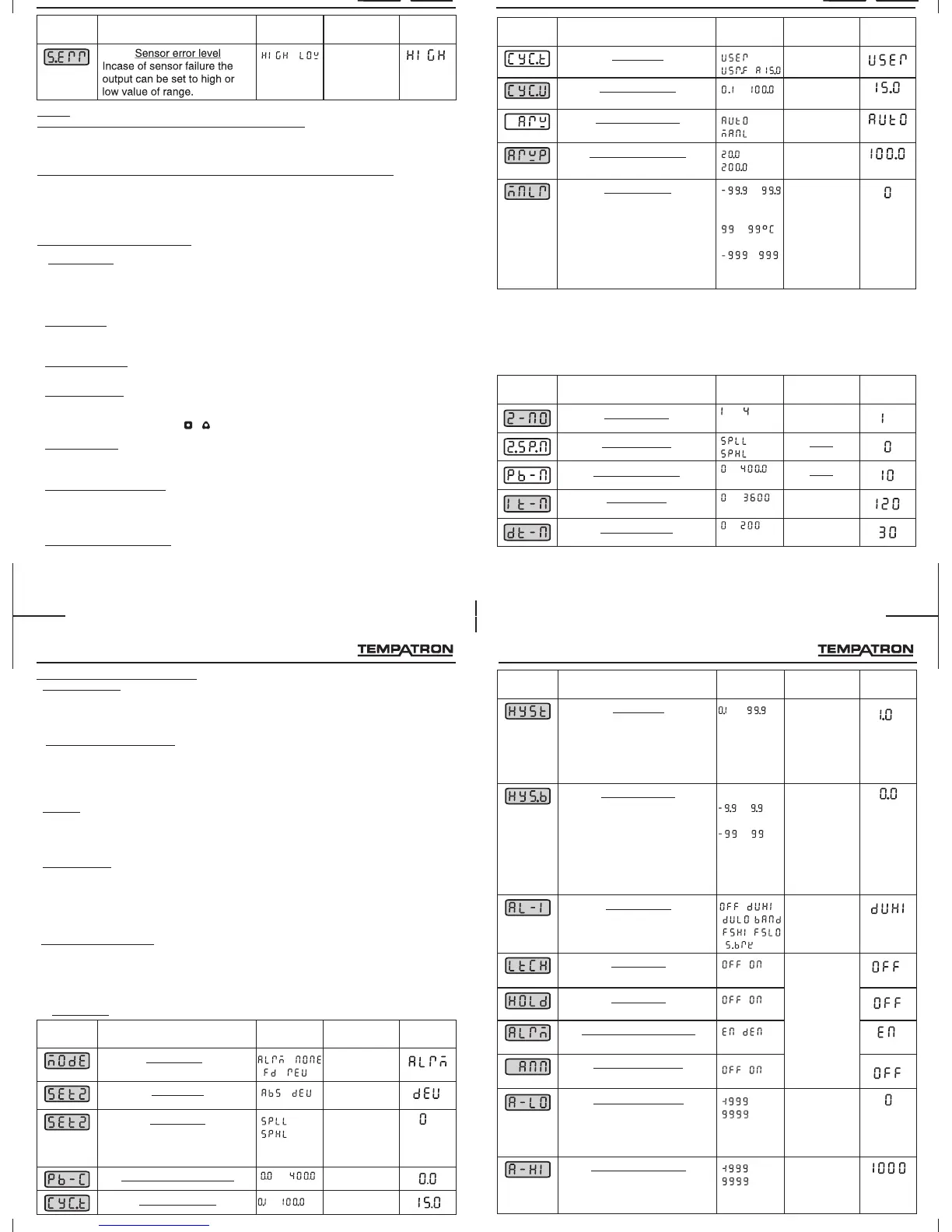

Display

Name&Description

Range

Display

condition

Default

value

Zonenumber

to

ZonePID=

YES(inlevel4)

Zonesetpoint

to

Proportionalband

Integraltime

Derivativetime

to

sec.

to

sec.

to

o

Pb-n>0

Pb-n>0

*NOTE: ForProportionalband,IntegraltimeandDerivativetimen=1to4

*

*

*

IfSetMode=ZoneandZonePID=YES,thefollowingparameterswill

beprompted.

IfSetMode=AllandZonePID=YES,Theparametersexceptthe

shadedones(i.e.Pb-1,It-1,dt-1)willbeprompted.

PIDcontrol

PIDcontrol

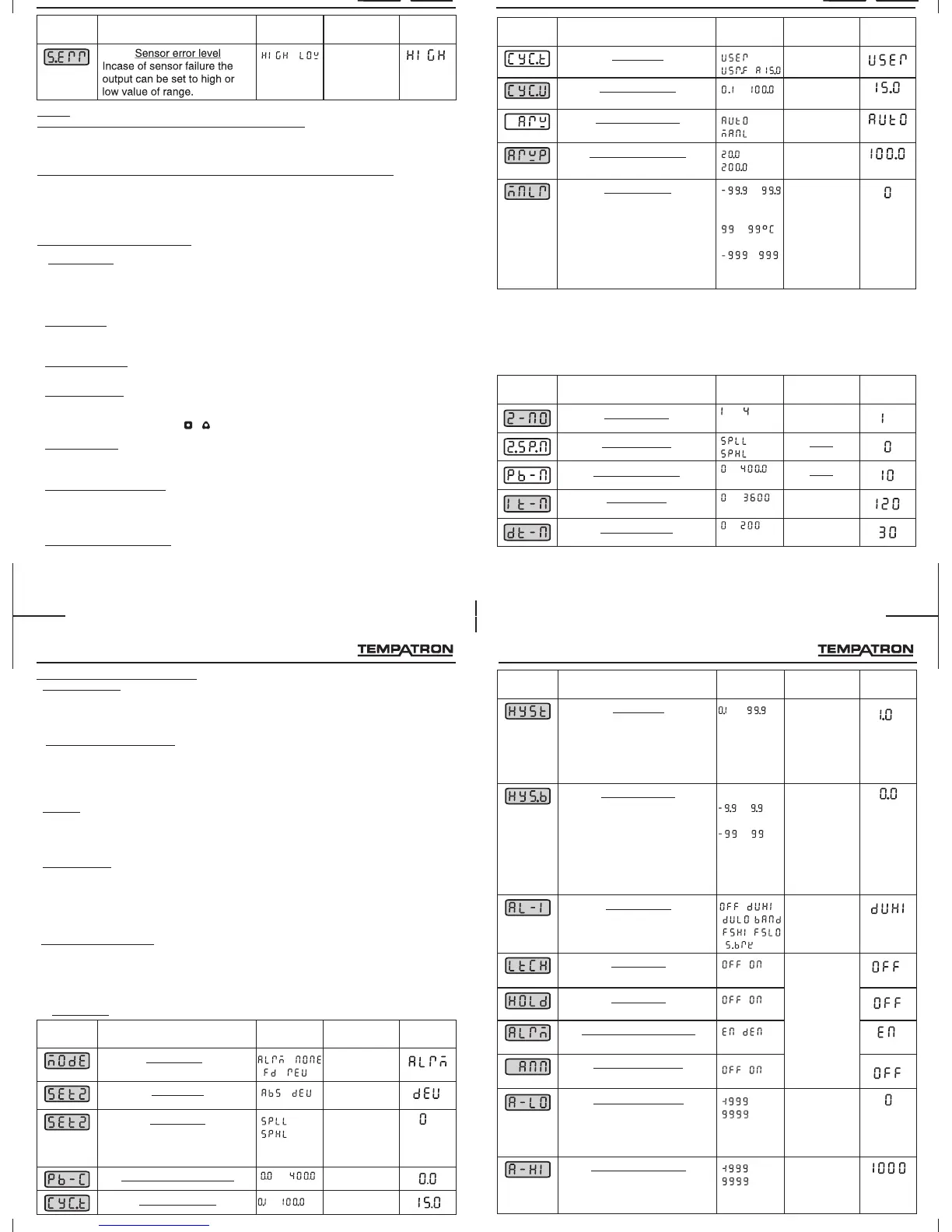

Display

Name&Description

Range

Display

condition

Default

value

/

NOTE:

HC mode

SET 2 MODE:

SET 2 TYPE:

ALARM MODES:

ALARM LATCH:

HOLD ALARM:

ALARM ANNUNCIATOR:

SENSOR ERROR LEVEL:

In only the following parameter will be prompted :-

In case of analog retransmission only the following parameters will be prompted:

1. Set 2 value - this parameter will be prompted as db (dead band)

2. Proportional band - cool (Pb-C)

3. Cycle time - cool (cyc.t)

1. A-LO : Analog low scaling.

2. A-HI : Analog high scaling.

3. S.ERR : Sensor error level.

Display is with fixed 1 resolution for TC/RTD and as per decimal point selected for analog

input.

AlrM: Set2 can be programmed as alarm.

NonE: If set2 is not required it can be programmed as none.

Fd: Set2 programmed in cooling mode.(output ON when above the setpoint).

rE: Set2 programmed in heating mode.(output ON when below the setpoint)

AbS: Absolute alarm is a self-existent alarm independent of the main set point.

DEV: The alarm is activated at an error on the main set point.

(Refer for detailed explanation).

When Latch is ON, the alarm once activated remains activated even when the error is

removed. To deactivate the alarm, it has to be acknowledged by selecting AL-NO from the

front online options and pressing + .

When HOLD is ON, in any alarm mode, it prevents an alarm signal on power-up. The alarm is

enabled only if the process temperature is within the alarm range.

When alarm annunciator is ON, during alarm condition, visual annunciation is given by the

upper display altering between AL-NO and process temperature where NO is the alarm

number. The annunciator may be disabled by selecting function ANN as OFF.

This parameter determines the analog retransmission output level in case of sensor failure.

For eg : In case of 4-20mA retransmission output, if the sensor error level is set to High, 20mA

will be available at the output at all times incase of input sensor failure.

O

PARAMETER EXPLANATIONS :

•

•

•

•

•

•

•

USER GUIDE

23

Programming.

ForAnalog

outputif

Mainoutput

=Relay2

Display

Name&Description

Range

Display

condition

Default

value

Hysteresis

to

O

C

1.Set2

mode=Fd/rEV/

ALrM(not

sensorbreak);

2.Heatcool

mode(

Pb-C=0)

Hysteresisbias

Alarm1mode

Alarmlatch

TC/RTD:

C

Analoginput:

to

asper

decimal

point

selected.

to

O

/

/ /

/ /

/

/

1.Set2

mode=Fd/rEV

/ALrM(not

sensorbreak);

2.Heat-cool

mode

(Pb-C=0)

Set2

mode=ALrM

These

parameters

arenot

promptedif

Alarm1mode

isOFF.

HoldAlarm

/

RelaystatusforAlarm1

AlarmAnnunciator

/

/

Analoglowscaling

Analoghighscaling

to

to ForAnalog

outputif

Mainoutput

=Relay2

22

Programming.

For Analog

retransmission

if Main output

= Relay2 in

Level 4

Display

Name&Description

Range

Display

condition

Default

value

Set2Mode *

Set2Type

/

/ /

/

NotforHeat-

coolmode.

Set2mode=

Fd/rEV.

5. -AUXILIARY OUTPUTMODESLEVEL 2

PARAMETER EXPLANATIONS :

!

!

!

!

!

AUTO TUNING:

OUTPUT POWER LIMITS:

TIMER:

CYCLE TIME:

ANTIRESET WINDUP:

Auto tuning is a function whereby the controller learns the process characteristics by itself

and automatically sets the required P,I and D values. The new P,I,D parameters will be

stored in non-volatile memory automatically. TUNE ON is indicated by ‘T’ LED blinking.

(For detailed explanations of PID parameters refer USER GUIDE).

These parameters are used to limit the minimum and maximum controller output power.

The output power lower limit will ensure that a minimum percentage of output (as per

requirement) is available in case any process disturbances or setpoint changes occur.

The output power high limit ensures that in case any process disturbance or set point

changes occur, the maximum value of output is limited to a value as per requirement.

TIMER is main output restart time. In this main output once turned OFF will turn ON only

after set time even if the temperature has increased and is more than the set temperature.

This is needed to prevent the compressor from restarting in a short time (less than the set

time).

There are 3 selectable modes for programming cycle time:

USEr: User can program the cycle time. The mode will be altered to AutO when put to

autotune.

Usr.F: User can fix the cycle time. This has the highest priority.

AutO: This is recommended. The cycle time value is calculated automatically during

autotune.

The anti-reset windup (ARW) inhibits the integral action until the PV is within the

proportional band thus reducing overshoot on start-up. If the selection is -

1. AutO: The value will be calculated automatically during autotune (Recommended).

2. ManL: The value can be fed manually by the user.

Set2Value

Proportionalband-Cool

to

to

Notprompted

ifSet2mode=

alarm&alarm

mode=S.Brk.

Heat-cool mode

Cycletime-Cool

to sec Pb-C>0

21

Programming.

NOTE: *-Ifset2mode=none,nootherparameterswillbeprompted.

Loading...

Loading...